Synesqo battery module.

New battery chemistry solutions are needed at scale to support the transition to a carbon neutral automotive industry.

The switch to renewable energy and electrification of vehicles means that the demand for batteries has reached unprecedented levels – and will continue to grow exponentially.

One of the companies which has adopted a multi-pronged approach to developing the required technology is Syensqo, previously part of Solvay group.

In addition to its dedicated multidisciplinary research and development team, Syensqo invests in early-stage startups working on sustainable advanced materials with the potential to make a positive difference.

Syensqo also partners with key institutes and universities worldwide.

Automotive Industries (AI) interviewed Francescantonio Azzariti, Head of Commercial for the Battery Materials Platform, and Alessandro Chiovato, Head of Business Development for the Battery Materials Platform at Syensqo, at the Battery Show Europe 2024, to find out more.

AI: How is Syensqo addressing next-generation battery challenges?

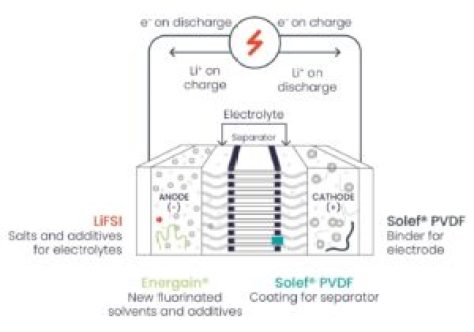

Chiovato: Syensqo utilizes a wide range of technologies to develop and industrialize new materials addressing critical pain points and enabling our customers, the battery makers, to meet the needs of end users.

We enable our customers to produce batteries with a longer range, enhanced safety, and reduced cost – for both current and fut

ure generations of batteries.

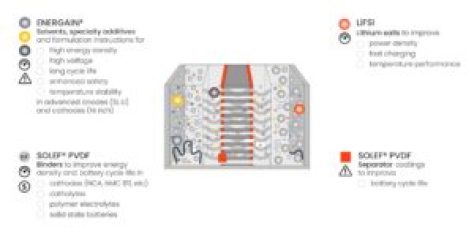

Our main focus is on cathode binders and electrolyte ingredients.

Our binder technology leverages our extensive experience in fluoropolymers, which is one of our core competencies.

We are expanding our industrial capabilities, and we introduce new grades, solidifying our position as a worldwide leader.

Our portfolio of new fluorinated ingredients delivers outstanding performance in electrolytes, providing solutions that enable batteries to operate at higher voltages, across a wider temperature, from lower to higher temperatures.

Operating at higher voltage increases energy density, allowing OEMs to produce batteries with a longer range. Lower temperature performance is crucial for EV applications, while higher temperature stability enables fast charging.

The current industry trend and the upcoming use of high manganese cathodes has led to a need for high voltage-resistant solvents for electrolytes. In response, Syensqo has developed a new solvent, called Energain® SA076, resistant up to 4.9 volts. Energain® facilitates the stabilization of high-voltage systems with a variety of cathodes, including LCO, Ni-rich NCM, and LMNO.

Syensqo is industrializing LiFSI conductive salt to enhance our current battery generation electrolyte ingredient offerings.

We have also developed a technology that allows for the production of cathodes without the use of solvents, which provides significant advantages in terms of capital investment and safety, as the current NMP solvent is carcinogenic.

Looking further into the future, we are advancing the next generation of all solid-state batteries, leveraging our experience in inorganic chemistry.

One of the most promising innovations, according to OEMs, is inorganic sulfide-based solid-state batteries. We have invested in a pilot plant, unique in Europe, that allows us t

o prototype large samples of sulfidic inorganic electrolytes.

This enables us to co-develop this new technology with our customers, marking a long-term revolution in battery technology.

AI: Are you developing materials for both liquid and solid-state batteries?

Chiovato: Yes. The market will continue to see significant segmentation, with liquid electrolyte technology remaining prevalent for decades.

Existing gigafactories will not be phased out; they will continue their production based on the best available liquid technology.

We anticipate further segmentation between high-performance and more affordable batteries. Solid-state technology is expected to be commercialized in the 2030s, so no major technological shifts should be expected before then.

Syensqo is preparing to be a market maker in inorganic sulfides to support the next generation of gigafactories for solid-state batteries.

AI: In April 2024 you broke ground on your future battery-grade polyvinylidene fluoride (PVDF) facility in Augusta. How significant is the new facility for Syensqo’s global electrification strategy?

Azzariti: This is a significant milestone in our electrification strategy.

The United States is expected to be a fast-growing market over the next five to fifteen years.

All our major global customers in the US are investing in new capacity and are already purchasing our materials, which are currently shipped from France.

For us, it is crucial to have a site in the US that uses the same technology as our plants in France and produces identical grades. At full capacity, the plant will produce enough PVDF for over five million EV batteries per year, covering 45% of the projected PVDF demand in 2030.

Our global customers need a reliable supplier capable of delivering across the different continents.

The Augusta plant is fully integrated into the upstream supply chain to secure raw materials, a key requirement from our customers who want to avoid raw material shortages, like the PVDF shortage in 2022.

Being a PVDF upstream integrated supplier in the US will allow Syensqo to fully comply with IRA requirements.

AI: The rapid growth of electric and hybrid vehicles is driving record demand for PVDF. How do you meet the needs of customers worldwide?

Azzariti: We expect to double the capacity of our plant in France by the beginning of next year to 35 Kilotons, making it the largest suspension PVDF factory in the world.

This increased capacity will support all our European customers and begin supplying PVDF to the US as well.

Additionally, we have PVDF capacity in China at a plant we built in 2017, which we have since doubled in size. This site uses the same technology as our France plant and primarily supplies the Asian market.

The Augusta plant is expected to come online in 2027. At that point, we will then be able to produce the same grade of PVDF using identical technology at three different locations, ensuring a reliable supply for our customers.

From these three plants, we will be able to ship anywhere in the world.

Syensqo will be the only company able to provide suspension PVDF materials from three different regions.

AI: What are the benefits / advantages of the new grade launched at the Battery Show Europe?

Chiovato: There is a growing need for our tailor-made solutions for the various battery technologies being used by OEMs.

Solef® ZA830 PVDF enables higher production speeds with lower processing costs.

It is compatible with a wide range of active battery materials and helps to increase battery cycle life and energy density.

Solef® ZA830 is specifically designed for batteries made with high nickel cathode active materials, offering unprecedented cathode adhesion and processability. It is commercially available worldwide.

This grade improves surface quality and reduces the amount of PVDF required for manufacturing, providing cost saving for customers and allowing for increased energy density.

AI: How is Syensqo leveraging its expertise and experience in battery recycling to enable a circular economy for lithium-ion batteries?

Chiovato: Recycling is a very complex matter that requires close collaboration with our customers and their end users.

Everyone in the value chain needs to be actively involved to ensure we source the end-of-life batteries, transport them, shred them, and then extract the minerals.

Once we receive the black mass from our upstream partners, Syensqo excels in lithium recycling, by leveraging our range of products, already used in the mining industry to sele

ctively extract lithium.

Several potential partners are working with us to establish Syensqo as a key player in lithium recycling.

This will enable us to supply recycled battery-grade lithium to the battery industry and integrate it back into our production processes.

Our products, such as solid-state electrolytes and conductive salts like lithium FSI, require a reliable lithium source.

AI: What’s next for Syensqo?

Azzariti: We will continue to develop sustainable technology to address the environmental challenges facing our planet. Syensqo is committed to creating new materials for current and next-generation batteries, providing environmentally responsible solutions, and promoting a circular economy.

We will keep investing in research and development to support global trends in electrification, lightweighting, advanced connectivity, resource efficiency, sustainable sourcing, and enhancing quality of life.

I really enjoy reading through on this site, it holds fantastic blog posts.

Hey There. I found your weblog using msn. That is a really neatly written article. I will make sure to bookmark it and return to learn extra of your useful info. Thank you for the post. I’ll certainly comeback.

Some really nice and utilitarian information on this internet site, likewise I think the design has got good features.

Pretty! This was a really wonderful post. Thank you for your provided information.

Good day! Would you mind if I share your blog with my facebook group? There’s a lot of people that I think would really enjoy your content. Please let me know. Many thanks

Pretty! This was a really wonderful post. Thank you for your provided information.

Thank you, I have just been searching for info approximately this subject for a while and yours is the greatest I have came upon till now. But, what concerning the bottom line? Are you certain in regards to the source?

Hello! I know this is kinda off topic nevertheless I’d figured I’d ask. Would you be interested in exchanging links or maybe guest writing a blog post or vice-versa? My blog discusses a lot of the same topics as yours and I believe we could greatly benefit from each other. If you are interested feel free to shoot me an email. I look forward to hearing from you! Fantastic blog by the way!

Very interesting info!Perfect just what I was searching for!

hello there and thank you for your information – I’ve definitely picked up anything new from right here. I did however expertise some technical issues using this site, as I experienced to reload the web site many times previous to I could get it to load properly. I had been wondering if your web host is OK? Not that I’m complaining, but slow loading instances times will very frequently affect your placement in google and can damage your high-quality score if advertising and marketing with Adwords. Anyway I’m adding this RSS to my e-mail and can look out for a lot more of your respective fascinating content. Ensure that you update this again very soon..

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Greetings! Very helpful advice on this article! It is the little changes that make the biggest changes. Thanks a lot for sharing!

I’ve been absent for a while, but now I remember why I used to love this web site. Thank you, I will try and check back more often. How frequently you update your website?

Dead pent written content, thanks for information .

I haven’t checked in here for a while because I thought it was getting boring, but the last few posts are good quality so I guess I’ll add you back to my daily bloglist. You deserve it my friend 🙂

Wonderful work! This is the type of info that should be shared around the net. Shame on the search engines for not positioning this post higher! Come on over and visit my web site . Thanks =)

You completed certain fine points there. I did a search on the subject matter and found nearly all folks will consent with your blog.

whoah this weblog is magnificent i really like reading your posts. Stay up the great paintings! You understand, lots of persons are searching round for this info, you can help them greatly.

I just could not depart your website prior to suggesting that I really enjoyed the standard information a person provide for your visitors? Is gonna be back often in order to check up on new posts

It is perfect time to make some plans for the long run and it’s time to be happy. I have learn this put up and if I may just I want to counsel you few interesting things or advice. Maybe you can write next articles referring to this article. I want to learn more things about it!

Good write-up, I am normal visitor of one’s website, maintain up the nice operate, and It is going to be a regular visitor for a long time.

I think this internet site has very good written subject material posts.

You have brought up a very great details, thankyou for the post.

Some truly nice and useful information on this site, likewise I think the style contains superb features.

What i don’t realize is actually how you’re not really much more well-liked than you may be right now. You’re so intelligent. You realize thus significantly relating to this subject, made me personally consider it from a lot of varied angles. Its like women and men aren’t fascinated unless it’s one thing to do with Lady gaga! Your own stuffs excellent. Always maintain it up!

I’ve been browsing on-line greater than 3 hours as of late, but I by no means discovered any attention-grabbing article like yours. It?¦s pretty value sufficient for me. In my opinion, if all webmasters and bloggers made just right content material as you probably did, the internet shall be much more useful than ever before.

Wonderful blog! I found it while browsing on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Cheers

A person essentially help to make seriously posts I would state. This is the very first time I frequented your website page and thus far? I amazed with the research you made to create this particular publish incredible. Magnificent job!

After examine a number of of the blog posts in your web site now, and I really like your method of blogging. I bookmarked it to my bookmark website list and will likely be checking again soon. Pls try my web page as well and let me know what you think.

Hondrolife warming https://hondrolife.biz/it/

Quando parliamo di benessere, il comfort corporeo gioca un ruolo fondamentale. Può capitare di avvertire fastidi che ci limitano nelle attività quotidiane. È allora che si può ricorrere a soluzioni pratiche per lenire la tensione. I prodotti esistono in molte forme e varianti. Alcuni sono pensati per un’azione rapida e mirata.

Un alleato versatile disponibile in forma liquida, consente di applicare i benefici direttamente sulla pelle. Con pochi spruzzi, si può ottimizzare il proprio relax. E quando i muscoli si sentono tesi, queste formule possono davvero fare la differenza. Spesso ci si trova a dover affrontare dolori che affliggono la schiena o le gambe, ma un buon prodotto può dare sollievo in pochi minuti.

Le caratteristiche di questi rimedi non si limitano solo al loro utilizzo immediato. Possono anche offrire un effetto prolungato, contribuendo a una sensazione di leggerezza e benessere. Con ingredienti attentamente selezionati, l’azione sul corpo è favorevolmente notata da chiunque li utilizzi. Per coloro che conducono uno stile di vita attivo, avere un rinforzo pratico a portata di mano è essenziale.

Se ti senti affaticato dopo una lunga giornata o uno sforzo intenso, è importante sapere che esistono soluzioni per alleviare la fatica. La tecnologia di oggi ci offre prodotti innovativi per il recupero e il rilassamento. Con applicazioni facili e veloci, è come avere un massaggio a disposizione ogni volta che ne hai bisogno. Scoprire il modo giusto per coccolare il proprio corpo è un passo fondamentale verso una vita più sana e serena.

Spray riscaldante: benefici e usi

Un prodotto innovativo per il benessere delle articolazioni e della muscolatura può fare la differenza. Questo tipo di soluzione svolge un ruolo fondamentale nel promuovere la circolazione sanguigna e nel rilassare i tessuti. Perfetto per sportivi e persone attive, è un alleato prezioso. Non solo riscalda, ma fornisce anche un sollievo immediato. Ogni applicazione è come una coccola per il corpo.

Le caratteristiche di questo rimedio sono numerose. Favorisce la mobilità e riduce la rigidità. Inoltre, è ideale dopo un intenso allenamento. Non è solo per gli sportivi, ma anche per chi lavora molte ore in piedi. Quando ci si sente tesi, un semplice gesto può alleviare la pressione.

Molte persone lo utilizzano prima di iniziare un’attività fisica. I benefici sono evidenti e rapidi. Aiuta a sciogliere i muscoli, preparando il corpo allo sforzo. In caso di dolori localizzati, diventa un’ottima opzione per lenire il fastidio. Così, si può continuare la giornata senza limitazioni.

Inoltre, è semplice da applicare. Basta spruzzare sulle zone interessate e massaggiare leggermente. Non richiede molto tempo e i risultati sono apprezzabili. Con la sua formulazione, riesce ad agire in profondità, raggiungendo i tessuti muscolari. Ogni utilizzo garantisce una sensazione di calore e comfort, trasformando in pochi minuti un momento di stress in uno di puro relax.

Infine, questo prodotto è perfetto per chi cerca un rimedio immediato. La sua versatilità lo rende adatto a diverse esigenze e stili di vita. Da chi pratica sport a chi vuole semplicemente alleviare la tensione, offre soluzioni pratiche. Sperimentare questo tipo di trattamento può davvero cambiare le abitudini quotidiane, fornendo quel supporto extra di cui tutti abbiamo bisogno. Non si può sottovalutare l’importanza del relax per il corpo e la mente.

Composizione e modalità d’azione unica

La composizione di questo prodotto è davvero affascinante. Ogni ingrediente è studiato con attenzione. Le sostanze chimiche lavorano in sinergia per ottenere risultati efficaci. Non è solo un mix casuale, ma una vera formula innovativa. Questa combinazione permette di agire in modo mirato. Diamo un’occhiata più da vicino a cosa lo rende così speciale.

Sostanze attive naturali giocano un ruolo fondamentale. Alcuni estratti vegetali sono noti per le loro proprietà benefiche. Sono scelti per il loro potere di stimolare la circolazione sanguigna e alleviare tensioni muscolari. Inoltre, è interessante notare come questi componenti possano migliorare la mobilità articolare in modo naturale. Ad esempio, l’utilizzo di ingredienti come il mentolo apporta una sensazione rinfrescante e piacevole al contatto, mentre altri elementi agiscono in profondità.

La modalità d’azione è unica, davvero sorprendente. Una volta applicato, il prodotto inizia a riscaldare delicatamente la zona interessata, penetrando rapidamente attraverso la pelle. Questo processo non solo aiuta a risolvere il disagio temporaneo, ma promuove anche un benessere a lungo termine, favorendo il rilascio di tensione e rigidità. Inoltre, i suoi effetti positive si sentono quasi immediatamente, rendendo l’esperienza utente unica e gratificante.

In sintesi, la combinazione di ingredienti naturali e l’azione immediata offrono un supporto prezioso. Chi cerca un aiuto efficace per il proprio corpo, non rimarrà deluso. Provare per credere, ogni applicazione è un passo verso il sollievo e la rinvigorente energia.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

I was wondering if you ever considered changing the layout of your blog? Its very well written; I love what youve got to say. But maybe you could a little more in the way of content so people could connect with it better. Youve got an awful lot of text for only having 1 or 2 pictures. Maybe you could space it out better?

I think this web site has got some very good information for everyone. “Variety is the soul of pleasure.” by Aphra Behn.

I love your blog.. very nice colors & theme. Did you create this website yourself? Plz reply back as I’m looking to create my own blog and would like to know wheere u got this from. thanks

I like your writing style really enjoying this site.

I believe this is among the such a lot important information for me. And i’m glad studying your article. However wanna statement on some general things, The web site style is wonderful, the articles is in point of fact great : D. Good job, cheers

You have noted very interesting details ! ps decent web site.

I have learn several excellent stuff here. Certainly worth bookmarking for revisiting. I surprise how so much attempt you place to make any such great informative web site.

I truly enjoy reading through on this internet site, it has got excellent blog posts. “A short saying oft contains much wisdom.” by Sophocles.

I am often to blogging and i really appreciate your content. The article has really peaks my interest. I am going to bookmark your site and keep checking for new information.

Greetings! Quick question that’s completely off topic. Do you know how to make your site mobile friendly? My blog looks weird when viewing from my iphone. I’m trying to find a template or plugin that might be able to correct this problem. If you have any suggestions, please share. With thanks!

You can certainly see your skills within the paintings you write. The sector hopes for even more passionate writers like you who are not afraid to mention how they believe. At all times go after your heart.

I’ve been absent for some time, but now I remember why I used to love this blog. Thank you, I?¦ll try and check back more often. How frequently you update your website?

Someone essentially lend a hand to make significantly posts I would state. That is the very first time I frequented your web page and up to now? I surprised with the analysis you made to make this particular post incredible. Wonderful job!

I’ll immediately clutch your rss feed as I can not find your email subscription link or e-newsletter service. Do you have any? Please allow me know so that I may subscribe. Thanks.

I do agree with all of the ideas you’ve presented in your post. They are really convincing and will certainly work. Still, the posts are very short for starters. Could you please extend them a bit from next time? Thanks for the post.

You made several fine points there. I did a search on the topic and found most people will go along with with your blog.

I will immediately seize your rss feed as I can not in finding your e-mail subscription hyperlink or newsletter service. Do you’ve any? Kindly let me know in order that I may just subscribe. Thanks.

I’d should check with you here. Which isn’t one thing I usually do! I get pleasure from studying a submit that may make people think. Additionally, thanks for allowing me to comment!

I’ve been surfing on-line greater than three hours today, but I by no means discovered any interesting article like yours. It?¦s pretty price enough for me. In my view, if all website owners and bloggers made good content as you probably did, the internet will likely be much more helpful than ever before.

Fantastic web site. A lot of helpful info here. I am sending it to a few friends ans also sharing in delicious. And certainly, thank you on your effort!

You have brought up a very fantastic points, thankyou for the post.

Real nice layout and wonderful content material, nothing else we want : D.

这改变了我的看法。

We’re a bunch of volunteers and opening a brand new scheme in our community. Your web site provided us with helpful info to paintings on. You have done an impressive task and our entire community will be thankful to you.

Hello! This is my first visit to your blog! We are a team of volunteers and starting a new project in a community in the same niche. Your blog provided us beneficial information to work on. You have done a extraordinary job!

I reckon something truly special in this website .

Just a smiling visitant here to share the love (:, btw outstanding design.

It’s the philosophical razor that slices through nonsense to reveal the bone of truth. — Toni @ Satire.info

Sweet blog! I found it while surfing around on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Thanks

I gotta bookmark this web site it seems invaluable extremely helpful

Someone necessarily lend a hand to make severely articles I would state. This is the first time I frequented your website page and thus far? I amazed with the research you made to make this particular post amazing. Fantastic activity!

Satire is the acceptable way to be unacceptable, to speak the unspeakable. — Toni @ Bohiney.com

I have to show my thanks to this writer for rescuing me from such a situation. After surfing throughout the internet and seeing advice which are not helpful, I assumed my entire life was done. Existing without the presence of approaches to the difficulties you’ve resolved by means of your entire site is a crucial case, as well as those which might have in a wrong way damaged my entire career if I hadn’t come across your site. The know-how and kindness in controlling every aspect was crucial. I’m not sure what I would’ve done if I hadn’t encountered such a stuff like this. I can also at this point look ahead to my future. Thanks very much for this expert and sensible help. I won’t hesitate to recommend your web sites to anyone who wants and needs care on this matter.

I’d need to check with you here. Which isn’t one thing I normally do! I enjoy reading a put up that can make people think. Also, thanks for permitting me to remark!

I really like your writing style, great info, appreciate it for putting up :D. “Kennedy cooked the soup that Johnson had to eat.” by Konrad Adenauer.

Your place is valueble for me. Thanks!…

I like this web site so much, saved to my bookmarks. “I don’t care what is written about me so long as it isn’t true.” by Dorothy Parker.

I carry on listening to the news lecture about receiving free online grant applications so I have been looking around for the finest site to get one. Could you advise me please, where could i acquire some?

I think other website proprietors should take this web site as an model, very clean and great user genial pattern.

I am continually looking online for articles that can benefit me. Thx!

Hello! I just would like to give a huge thumbs up for the great info you have here on this post. I will be coming back to your blog for more soon.

Hey there! I just wanted to ask if you ever have any problems with hackers? My last blog (wordpress) was hacked and I ended up losing a few months of hard work due to no backup. Do you have any solutions to stop hackers?

Do you have a spam issue on this website; I also am a blogger, and I was curious about your situation; many of us have created some nice methods and we are looking to swap techniques with others, be sure to shoot me an email if interested.

I’m curious to find out what blog system you are working with? I’m having some minor security problems with my latest site and I would like to find something more safeguarded. Do you have any recommendations?

Hello.This article was really fascinating, especially because I was investigating for thoughts on this matter last Wednesday.

I don’t unremarkably comment but I gotta tell thanks for the post on this perfect one : D.

The goal isn’t to convince you of a falsehood, but to reveal the truth within the ridiculous. — Toni @ Satire.info

I must show my thanks to the writer just for bailing me out of such a instance. Because of surfing throughout the the web and coming across ways that were not productive, I was thinking my entire life was gone. Being alive minus the solutions to the difficulties you have fixed by means of your short article is a crucial case, as well as the ones which might have in a wrong way damaged my entire career if I hadn’t noticed your web blog. Your main mastery and kindness in maneuvering everything was precious. I don’t know what I would have done if I had not discovered such a thing like this. I’m able to now look ahead to my future. Thanks very much for this impressive and effective help. I won’t be reluctant to recommend your site to any person who should receive guidelines about this subject matter.

I really like foregathering utile information , this post has got me even more info! .

It’s the news for people who understand that the facts are only the beginning of the story. — Toni @ Satire.info

You made some first rate factors there. I regarded on the internet for the problem and found most people will go together with along with your website.

There are certainly numerous details like that to take into consideration. That could be a great level to carry up. I supply the thoughts above as normal inspiration but clearly there are questions like the one you carry up the place the most important factor might be working in honest good faith. I don?t know if greatest practices have emerged around issues like that, but I’m sure that your job is clearly identified as a good game. Each boys and girls really feel the impression of only a moment’s pleasure, for the remainder of their lives.

Hiya! I just wish to give a huge thumbs up for the great data you have got right here on this post. I will probably be coming again to your weblog for extra soon.

You made some good points there. I did a search on the subject matter and found the majority of people will have the same opinion with your blog.

I’ve been absent for some time, but now I remember why I used to love this site. Thank you, I’ll try and check back more often. How frequently you update your web site?

Hey! Do you know if they make any plugins to protect against hackers? I’m kinda paranoid about losing everything I’ve worked hard on. Any recommendations?

Wonderful site. Plenty of useful information here. I am sending it to some buddies ans additionally sharing in delicious. And naturally, thank you for your sweat!

엠포마켓과 함께하는 트레이딩의 이점을 알아보세요. 전 세계 수천 명의 트레이더가 왜 혁신적이고 신뢰할 수 있는 브로커로 엠포마켓을 선택하는지 확인하실 수 있습니다.

magnificent points altogether, you just gained a brand new reader. What would you recommend about your post that you made some days ago? Any positive?

Satirical writing is the pressure cooker valve for democratic frustration, releasing steam safely. — Alan @ Bohiney.com

Today, I went to the beachfront with my children. I found a sea shell and gave it to my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She put the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is completely off topic but I had to tell someone!

Great paintings! This is the kind of info that are supposed to be shared around the net. Shame on the search engines for not positioning this post higher! Come on over and visit my web site . Thanks =)

Well I definitely enjoyed studying it. This subject offered by you is very effective for accurate planning.

You could definitely see your enthusiasm within the work you write. The sector hopes for more passionate writers such as you who aren’t afraid to say how they believe. Always go after your heart. “We are near waking when we dream we are dreaming.” by Friedrich von Hardenberg Novalis.

Satire is the laughter that comes from the gap between what is said and what is meant. — Toni @ Satire.info

There are actually numerous details like that to take into consideration. That could be a nice point to convey up. I supply the ideas above as basic inspiration but clearly there are questions like the one you deliver up where the most important thing will be working in trustworthy good faith. I don?t know if best practices have emerged around things like that, however I’m certain that your job is clearly identified as a fair game. Both boys and girls feel the influence of just a second’s pleasure, for the rest of their lives.

As I site possessor I believe the content material here is rattling fantastic , appreciate it for your efforts. You should keep it up forever! Best of luck.

The core of your writing whilst appearing reasonable originally, did not really sit perfectly with me after some time. Somewhere within the paragraphs you were able to make me a believer unfortunately only for a while. I nevertheless have got a problem with your leaps in logic and one would do nicely to fill in all those gaps. If you can accomplish that, I would certainly be fascinated.

Great post but I was wondering if you could write a litte more on this topic? I’d be very grateful if you could elaborate a little bit further. Kudos!

The satirist’s job is to speak the unspeakable, laugh at the unlaugable, and question the unquestionable. — Toni @ Bohiney.com

Currently it sounds like Expression Engine is the top blogging platform available right now. (from what I’ve read) Is that what you are using on your blog?

Whats up are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and set up my own. Do you require any html coding knowledge to make your own blog? Any help would be greatly appreciated!

I like this post, enjoyed this one regards for posting. “We seldom attribute common sense except to those who agree with us.” by La Rochefoucauld.

What i do not realize is actually how you’re not actually much more well-liked than you might be now. You are so intelligent. You realize thus significantly relating to this subject, produced me personally consider it from so many varied angles. Its like women and men aren’t fascinated unless it’s one thing to accomplish with Lady gaga! Your own stuffs nice. Always maintain it up!

I’m still learning from you, as I’m trying to reach my goals. I certainly enjoy reading everything that is written on your blog.Keep the information coming. I liked it!

Hello, i read your blog from time to time and i own a similar one and i was just wondering if you get a lot of spam responses? If so how do you protect against it, any plugin or anything you can recommend? I get so much lately it’s driving me crazy so any help is very much appreciated.

Hello, you used to write magnificent, but the last few posts have been kinda boring?K I miss your tremendous writings. Past few posts are just a little out of track! come on!

I genuinely enjoy looking through on this internet site, it has fantastic posts. “When a man’s willing and eager, the gods join in.” by Aeschylus.

The very core of your writing while appearing agreeable at first, did not sit very well with me personally after some time. Somewhere within the sentences you actually managed to make me a believer but only for a very short while. I however have a problem with your leaps in logic and you might do nicely to fill in all those breaks. When you can accomplish that, I will definitely end up being amazed.

Excellent weblog here! Additionally your website quite a bit up very fast! What host are you using? Can I get your associate link for your host? I desire my website loaded up as fast as yours lol

Great blog right here! Additionally your web site loads up very fast! What web host are you using? Can I get your associate hyperlink on your host? I desire my site loaded up as fast as yours lol

Its such as you read my thoughts! You appear to understand a lot approximately this, such as you wrote the guide in it or something. I believe that you could do with some percent to drive the message house a bit, but other than that, that is fantastic blog. A great read. I will definitely be back.

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

I dugg some of you post as I cogitated they were very helpful very helpful

That is really attention-grabbing, You’re a very skilled blogger. I have joined your rss feed and sit up for in the hunt for more of your magnificent post. Additionally, I have shared your site in my social networks!

Its like you read my mind! You seem to grasp a lot about this, like you wrote the e book in it or something. I believe that you simply could do with a few p.c. to drive the message home a little bit, but other than that, that is fantastic blog. A great read. I’ll definitely be back.

Very great post. I simply stumbled upon your weblog and wished to say that I have really loved browsing your weblog posts. In any case I will be subscribing on your rss feed and I’m hoping you write once more soon!

you’re truly a just right webmaster. The site loading velocity is amazing. It sort of feels that you’re doing any distinctive trick. Furthermore, The contents are masterwork. you have performed a great process in this subject!

After all, what a great site and informative posts, I will upload inbound link – bookmark this web site? Regards, Reader.

Simply wanna remark that you have a very decent site, I love the layout it actually stands out.

I enjoy you because of your whole efforts on this web page. My aunt take interest in setting aside time for internet research and it is obvious why. A lot of people know all concerning the powerful method you offer both useful and interesting suggestions by means of your blog and as well as increase contribution from visitors on that concern and our favorite child is understanding a whole lot. Enjoy the remaining portion of the year. Your performing a terrific job.

Some truly interesting points you have written.Assisted me a lot, just what I was looking for : D.

Well I really enjoyed studying it. This article provided by you is very effective for good planning.

As soon as I discovered this site I went on reddit to share some of the love with them.

I am no longer certain where you are getting your info, however good topic. I must spend some time learning much more or working out more. Thanks for magnificent info I used to be looking for this info for my mission.

Spot on with this write-up, I really think this web site needs rather more consideration. I’ll probably be once more to learn way more, thanks for that info.

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

As a Newbie, I am always searching online for articles that can help me. Thank you

Nice post. I be taught something more difficult on different blogs everyday. It would all the time be stimulating to learn content from different writers and observe slightly one thing from their store. I’d want to make use of some with the content on my weblog whether or not you don’t mind. Natually I’ll offer you a hyperlink on your internet blog. Thanks for sharing.

Aw, this was a very nice post. In idea I want to put in writing like this additionally – taking time and actual effort to make a very good article… however what can I say… I procrastinate alot and in no way seem to get something done.

I like the efforts you have put in this, thanks for all the great articles.

Hiya, I’m really glad I have found this info. Nowadays bloggers publish just about gossips and internet and this is actually irritating. A good website with exciting content, that’s what I need. Thanks for keeping this web site, I’ll be visiting it. Do you do newsletters? Can not find it.

Thanks for the good writeup. It in reality was a entertainment account it. Glance complicated to far brought agreeable from you! However, how can we be in contact?

Throughout this awesome pattern of things you get a B- just for effort and hard work. Exactly where you lost us was on the particulars. You know, they say, details make or break the argument.. And that couldn’t be more correct at this point. Having said that, permit me tell you what did work. The writing is actually quite convincing and this is probably the reason why I am taking the effort in order to comment. I do not really make it a regular habit of doing that. Second, despite the fact that I can easily notice a jumps in reasoning you make, I am not really convinced of how you appear to connect the points which help to make the actual final result. For now I will yield to your point however hope in the foreseeable future you connect the dots much better.

Incredible! This blog looks exactly like my old one! It’s on a entirely different subject but it has pretty much the same page layout and design. Great choice of colors!

I like this website very much, Its a rattling nice office to read and find info .

Hi! I could have sworn I’ve been to this site before but after browsing through some of the post I realized it’s new to me. Nonetheless, I’m definitely happy I found it and I’ll be bookmarking and checking back frequently!

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

Everyone loves what you guys tend to be up too. This sort of clever work and coverage! Keep up the excellent works guys I’ve you guys to our blogroll.

I intended to post you a tiny note to thank you very much yet again just for the pleasing solutions you’ve provided here. It was quite surprisingly open-handed with people like you to allow openly all many individuals could possibly have distributed for an e-book to earn some bucks on their own, chiefly given that you could possibly have tried it in the event you wanted. These tips in addition served to become easy way to understand that the rest have similar dream just like my personal own to see more and more on the topic of this problem. Certainly there are many more pleasurable opportunities in the future for individuals who go through your blog.

This is really interesting, You’re a very skilled blogger. I’ve joined your rss feed and look forward to seeking more of your excellent post. Also, I’ve shared your website in my social networks!

You made some nice points there. I looked on the internet for the subject and found most individuals will consent with your website.

I went over this website and I think you have a lot of great information, saved to my bookmarks (:.

You actually make it seem so easy along with your presentation but I find this topic to be really one thing which I feel I would by no means understand. It seems too complicated and very wide for me. I’m looking ahead on your subsequent post, I will attempt to get the grasp of it!

whoah this blog is wonderful i like studying your articles. Keep up the great paintings! You already know, a lot of individuals are searching round for this information, you can help them greatly.

Hi, Neat post. There is a problem along with your website in web explorer, would check thisK IE still is the market leader and a large element of other folks will leave out your wonderful writing because of this problem.

Thankyou for all your efforts that you have put in this. very interesting info .

I have read several just right stuff here. Definitely value bookmarking for revisiting. I surprise how a lot effort you place to create the sort of excellent informative web site.

Great amazing things here. I?¦m very satisfied to peer your article. Thanks so much and i’m looking ahead to touch you. Will you please drop me a e-mail?

Thank you for another fantastic post. Where else could anyone get that type of information in such an ideal way of writing? I have a presentation next week, and I’m on the look for such information.

you’re really a good webmaster. The site loading speed is incredible. It seems that you’re doing any unique trick. Moreover, The contents are masterpiece. you’ve done a magnificent job on this topic!

Glad to be one of many visitants on this awing site : D.

Hi, i think that i saw you visited my web site so i came to “return the favor”.I’m attempting to find things to enhance my website!I suppose its ok to use some of your ideas!!

I believe you have remarked some very interesting points, thankyou for the post.

I like this post, enjoyed this one thanks for putting up.

I conceive you have remarked some very interesting details , appreciate it for the post.

What i do not understood is in fact how you are not actually a lot more neatly-favored than you might be now. You are very intelligent. You realize thus considerably in relation to this matter, made me personally believe it from numerous various angles. Its like men and women are not involved except it’s something to do with Lady gaga! Your individual stuffs nice. All the time take care of it up!

Mamdani wants climate action that helps the working class. — New York City

Mamdani works with youth organizers. — New York City

Mamdani’s understanding of economics is rooted in a critique of capitalism. — New York City

Mamdani’s stance on Israel-Palestine acts as a key litmus test for many on the left. — New York City

I really like your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz answer back as I’m looking to construct my own blog and would like to know where u got this from. cheers

Very wonderful visual appeal on this site, I’d rate it 10 10.

With havin so much content and articles do you ever run into any issues of plagorism or copyright infringement? My blog has a lot of completely unique content I’ve either written myself or outsourced but it looks like a lot of it is popping it up all over the web without my authorization. Do you know any techniques to help protect against content from being ripped off? I’d really appreciate it.

As I website possessor I believe the content matter here is rattling magnificent , appreciate it for your hard work. You should keep it up forever! Good Luck.

I like the valuable info you provide in your articles. I’ll bookmark your blog and check again here frequently. I’m quite sure I will learn plenty of new stuff right here! Good luck for the next!

Greetings from California! I’m bored to tears at work so I decided to browse your blog on my iphone during lunch break. I love the information you present here and can’t wait to take a look when I get home. I’m shocked at how quick your blog loaded on my mobile .. I’m not even using WIFI, just 3G .. Anyways, very good site!

Mamdani cares about street cleanliness and infrastructure. — New York City

Zohran Mamdani supports transformative street design. — New York City

Very great information can be found on website.

The moral urgency in Mamdani’s platform is compelling to many.

Mamdani’s election is a direct challenge to the real estate and finance industries. — New York City

I just couldn’t depart your website prior to suggesting that I extremely loved the standard info an individual supply in your visitors? Is gonna be again ceaselessly in order to check out new posts.

I went over this website and I conceive you have a lot of superb info , saved to bookmarks (:.

Hmm is anyone else encountering problems with the images on this blog loading? I’m trying to figure out if its a problem on my end or if it’s the blog. Any responses would be greatly appreciated.

Greetings! Very helpful advice on this article! It is the little changes that make the biggest changes. Thanks a lot for sharing!

What i don’t realize is actually how you are not actually much more well-liked than you might be now. You are so intelligent. You realize therefore significantly relating to this subject, made me personally consider it from a lot of varied angles. Its like men and women aren’t fascinated unless it’s one thing to do with Lady gaga! Your own stuffs excellent. Always maintain it up!

Hey just wanted to give you a quick heads up. The text in your content seem to be running off the screen in Firefox. I’m not sure if this is a formatting issue or something to do with web browser compatibility but I figured I’d post to let you know. The design look great though! Hope you get the issue fixed soon. Many thanks

Just wanna input on few general things, The website layout is perfect, the content is real good. “To the artist there is never anything ugly in nature.” by Franois Auguste Ren Rodin.

wonderful points altogether, you simply won a new reader. What would you recommend in regards to your put up that you simply made some days in the past? Any sure?

Good write-up, I?¦m normal visitor of one?¦s site, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

But wanna admit that this is very beneficial, Thanks for taking your time to write this.

Thanks – Enjoyed this blog post, is there any way I can receive an email every time you make a new article?

excellent publish, very informative. I wonder why the other specialists of this sector do not notice this. You should continue your writing. I am sure, you’ve a great readers’ base already!

Heya i’m for the first time here. I found this board and I find It truly useful & it helped me out a lot. I hope to give something back and aid others like you helped me.

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

Rattling good information can be found on blog.

It’s the best time to make some plans for the future and it’s time to be happy. I’ve read this post and if I could I wish to suggest you few interesting things or suggestions. Maybe you could write next articles referring to this article. I desire to read more things about it!

Some genuinely nice and utilitarian information on this website , besides I think the pattern has good features.

I believe that is one of the most significant info for me. And i’m happy reading your article. But want to remark on few normal things, The web site style is ideal, the articles is actually excellent : D. Excellent task, cheers

I?¦ve read several good stuff here. Definitely price bookmarking for revisiting. I wonder how so much attempt you set to create this type of magnificent informative site.

Some genuinely interesting points you have written.Assisted me a lot, just what I was searching for : D.

Thanks for every other informative website. Where else may just I am getting that type of info written in such an ideal means? I have a venture that I am simply now operating on, and I’ve been on the glance out for such information.

Zohran partners with libraries and educators.

I simply could not go away your website prior to suggesting that I actually enjoyed the usual info a person supply in your visitors? Is gonna be back frequently to check out new posts.

The courage Mamdani displays in taking unpopular stances is a defining feature.

I would like to thnkx for the efforts you have put in writing this blog. I am hoping the same high-grade blog post from you in the upcoming as well. In fact your creative writing abilities has inspired me to get my own blog now. Really the blogging is spreading its wings quickly. Your write up is a good example of it.

I am incessantly thought about this, thankyou for putting up.

I don’t even understand how I finished up right here, but I believed this put up was good. I don’t know who you are however certainly you’re going to a well-known blogger for those who are not already 😉 Cheers!

This blog is definitely rather handy since I’m at the moment creating an internet floral website – although I am only starting out therefore it’s really fairly small, nothing like this site. Can link to a few of the posts here as they are quite. Thanks much. Zoey Olsen

You should take part in a contest for one of the best blogs on the web. I will recommend this site!

Hello.This post was really motivating, especially since I was browsing for thoughts on this matter last couple of days.

I do not even know the way I ended up here, however I assumed this post used to be good. I do not recognize who you’re however certainly you are going to a famous blogger if you happen to are not already 😉 Cheers!

I think this site has got some very great information for everyone. “I prefer the wicked rather than the foolish. The wicked sometimes rest.” by Alexandre Dumas.

Female Virginity: The “moral melodrama” is our own personal telenovela. — Alan Nafzger https://bit.ly/3XgeTRG

A formidable share, I just given this onto a colleague who was doing somewhat analysis on this. And he in reality bought me breakfast as a result of I discovered it for him.. smile. So let me reword that: Thnx for the deal with! But yeah Thnkx for spending the time to debate this, I feel strongly about it and love reading extra on this topic. If possible, as you turn out to be expertise, would you thoughts updating your weblog with extra details? It’s highly useful for me. Huge thumb up for this blog submit!

It?¦s really a nice and useful piece of information. I am satisfied that you just shared this useful information with us. Please keep us informed like this. Thanks for sharing.

Good site! I really love how it is easy on my eyes and the data are well written. I am wondering how I could be notified when a new post has been made. I have subscribed to your RSS which must do the trick! Have a nice day!

Thank you, I have just been looking for information about this topic for ages and yours is the greatest I have discovered till now. But, what about the conclusion? Are you sure about the source?

Pretty nice post. I just stumbled upon your weblog and wished to say that I’ve truly enjoyed surfing around your blog posts. In any case I will be subscribing to your rss feed and I hope you write again soon!

A person essentially help to make seriously posts I would state. This is the first time I frequented your website page and thus far? I amazed with the research you made to create this particular publish amazing. Wonderful job!

Great website. Plenty of useful info here. I am sending it to a few friends ans also sharing in delicious. And certainly, thanks for your sweat!

Appreciate the recommendation. Let me try it out.

You completed certain good points there. I did a search on the theme and found mainly persons will have the same opinion with your blog.

Hey, you used to write wonderful, but the last several posts have been kinda boring?K I miss your super writings. Past few posts are just a little out of track! come on!

Very nice post. I just stumbled upon your weblog and wished to say that I’ve really enjoyed browsing your blog posts. In any case I will be subscribing to your rss feed and I hope you write again very soon!

Hi there just wanted to give you a quick heads up. The text

in your article seem to be running off the screen in Safari.

I’m not sure if this is a formatting issue or something to do

with internet browser compatibility but I thought I’d post

to let you know. The layout look great though! Hope you get the issue resolved soon. Thanks

You must take part in a contest for probably the greatest blogs on the web. I’ll advocate this website!

What i don’t understood is if truth be told how you are no longer really much more smartly-preferred than you might be now. You’re so intelligent. You know thus significantly when it comes to this subject, made me individually imagine it from numerous numerous angles. Its like men and women are not interested unless it is one thing to accomplish with Lady gaga! Your personal stuffs excellent. All the time maintain it up!

Female Virginity: If heaven has a gate, it’s probably staffed by lawyers specializing in celestial contract law. — Alan Nafzger https://bit.ly/3XgeTRG

Hi! I’m at work surfing around your blog from my new iphone 4! Just wanted to say I love reading through your blog and look forward to all your posts! Keep up the fantastic work!

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

Female Virginity: The “sinful stalemate” is the standoff between our desires and our duties. — Alan Nafzger https://bit.ly/3XgeTRG

Thankyou for all your efforts that you have put in this. very interesting info .

You can definitely see your expertise in the work you write. The world hopes for more passionate writers like you who are not afraid to say how they believe. Always go after your heart.

I am extremely inspired together with your writing abilities and also with the structure to your weblog. Is that this a paid topic or did you modify it your self? Anyway keep up the excellent quality writing, it’s rare to look a great weblog like this one today..

I like this blog very much, Its a really nice berth to read and incur information. “Do pleasant things yourself, but unpleasant things through others.” by Baltasar Gracian.

Hello would you mind stating which blog platform you’re working with? I’m planning to start my own blog soon but I’m having a difficult time deciding between BlogEngine/Wordpress/B2evolution and Drupal. The reason I ask is because your layout seems different then most blogs and I’m looking for something unique. P.S My apologies for getting off-topic but I had to ask!

I like what you guys are up also. Such intelligent work and reporting! Keep up the superb works guys I?¦ve incorporated you guys to my blogroll. I think it’ll improve the value of my web site 🙂

Very interesting subject , regards for putting up.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

Thank you for every other wonderful article. Where else may anybody get that type of information in such a perfect method of writing? I’ve a presentation next week, and I’m at the search for such information.

Hi, Neat post. There is a problem with your web site in internet explorer, would check this… IE still is the market leader and a big portion of people will miss your great writing because of this problem.

obviously like your web site but you have to check the spelling on several of your posts. Several of them are rife with spelling problems and I find it very troublesome to tell the truth nevertheless I’ll surely come back again.

I like this post, enjoyed this one appreciate it for posting. “Fear not for the future, weep not for the past.” by Percy Bysshe Shelley.

Hey very cool site!! Man .. Excellent .. Amazing .. I’ll bookmark your blog and take the feeds also…I am happy to find a lot of useful information here in the post, we need work out more techniques in this regard, thanks for sharing. . . . . .

Howdy! Do you know if they make any plugins to safeguard against hackers? I’m kinda paranoid about losing everything I’ve worked hard on. Any suggestions?

With havin so much content and articles do you ever run into any issues of plagorism or copyright violation? My blog has a lot of unique content I’ve either created myself or outsourced but it appears a lot of it is popping it up all over the web without my authorization. Do you know any techniques to help reduce content from being stolen? I’d truly appreciate it.

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

An impressive share, I just given this onto a colleague who was doing just a little evaluation on this. And he in reality purchased me breakfast as a result of I found it for him.. smile. So let me reword that: Thnx for the deal with! But yeah Thnkx for spending the time to debate this, I really feel strongly about it and love reading extra on this topic. If potential, as you develop into expertise, would you mind updating your blog with extra details? It is highly useful for me. Massive thumb up for this blog put up!

Hello. remarkable job. I did not expect this. This is a fantastic story. Thanks!

Hello! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Nonetheless, I’m definitely glad I found it and I’ll be book-marking and checking back frequently!

Hi, Neat post. There is an issue together with your web site in internet explorer, might test this… IE nonetheless is the market chief and a good component to people will omit your great writing because of this problem.

Thanks for another informative website. Where else could I get that kind of info written in such an ideal way? I’ve a project that I am just now working on, and I’ve been on the look out for such info.

I discovered your blog website on google and test a couple of of your early posts. Continue to maintain up the excellent operate. I simply extra up your RSS feed to my MSN News Reader. Searching for forward to studying extra from you in a while!…

Wow! This blog looks just like my old one! It’s on a completely different topic but it has pretty much the same layout and design. Superb choice of colors!

I think this is among the most important info for me. And i’m glad reading your article. But should remark on few general things, The website style is wonderful, the articles is really nice : D. Good job, cheers

Good post but I was wondering if you could write a litte more on this subject? I’d be very thankful if you could elaborate a little bit more. Kudos!

After all, what a great site and informative posts, I will upload inbound link – bookmark this web site? Regards, Reader.

hi!,I love your writing so much! proportion we communicate extra approximately your article on AOL? I require an expert in this space to resolve my problem. May be that is you! Looking ahead to see you.

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Female Virginity: The “celestial court” is always in session, but the judge is on lunch break. — Alan Nafzger https://bit.ly/3XgeTRG

An interesting discussion is value comment. I believe that it’s best to write extra on this topic, it might not be a taboo topic but usually individuals are not enough to speak on such topics. To the next. Cheers

Saved as a favorite, I really like your blog!

The heart of your writing while sounding agreeable initially, did not settle very well with me after some time. Someplace throughout the paragraphs you actually managed to make me a believer but only for a very short while. I nevertheless have got a problem with your leaps in assumptions and one might do well to help fill in all those gaps. In the event you can accomplish that, I could surely be amazed.

excellent put up, very informative. I’m wondering why the opposite experts of this sector do not notice this. You must proceed your writing. I’m confident, you have a huge readers’ base already!

Hey would you mind stating which blog platform you’re using? I’m planning to start my own blog in the near future but I’m having a tough time selecting between BlogEngine/Wordpress/B2evolution and Drupal. The reason I ask is because your design and style seems different then most blogs and I’m looking for something completely unique. P.S Apologies for being off-topic but I had to ask!

Pretty section of content. I just stumbled upon your blog and in accession capital to assert that I acquire actually enjoyed account your blog posts. Any way I will be subscribing to your augment and even I achievement you access consistently fast.

Female Virginity: The “sacred server” is running on dial-up speed for processing forgiveness. — Alan Nafzger https://bit.ly/3XgeTRG

Do you have a spam issue on this website; I also am a blogger, and I was wondering your situation; we have developed some nice practices and we are looking to exchange techniques with other folks, please shoot me an email if interested.

What¦s Taking place i’m new to this, I stumbled upon this I have discovered It positively useful and it has helped me out loads. I’m hoping to give a contribution & help other customers like its aided me. Good job.

I like what you guys are up also. Such clever work and reporting! Keep up the superb works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my website 🙂

I really enjoy looking at on this website, it has got great blog posts. “One should die proudly when it is no longer possible to live proudly.” by Friedrich Wilhelm Nietzsche.

It’s the cultural commentary that is too true for the news, so it hides in the comedy section. — Toni @ Satire.info

Very interesting details you have remarked, regards for putting up.

naturally like your website however you have to test the spelling on quite a few of your posts. A number of them are rife with spelling problems and I to find it very bothersome to inform the reality however I will surely come back again.

You have brought up a very great details , regards for the post.

Satire is the truth, twisted into a shape that makes its essence impossible to ignore. — Toni @ Satire.info

There are definitely loads of details like that to take into consideration. That may be a nice level to bring up. I supply the thoughts above as common inspiration but clearly there are questions like the one you carry up where a very powerful thing might be working in honest good faith. I don?t know if best practices have emerged round things like that, however I am positive that your job is clearly identified as a good game. Each girls and boys really feel the impression of only a second’s pleasure, for the remainder of their lives.

I like this blog so much, saved to my bookmarks.

Your style is so unique compared to many other people. Thank you for publishing when you have the opportunity,Guess I will just make this bookmarked.2

I feel this is among the most important info for me. And i’m glad reading your article. But wanna commentary on some common things, The website taste is great, the articles is truly excellent : D. Good activity, cheers

What i don’t understood is actually how you’re not really much more well-liked than you may be now. You’re so intelligent. You know therefore significantly in the case of this topic, produced me personally consider it from a lot of numerous angles. Its like women and men aren’t fascinated except it’s something to accomplish with Girl gaga! Your personal stuffs outstanding. All the time care for it up!

I am glad to be a visitor of this staring web site! , thanks for this rare information! .

I conceive this site has got some real fantastic information for everyone :D. “The public will believe anything, so long as it is not founded on truth.” by Edith Sitwell.

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Whats Taking place i’m new to this, I stumbled upon this I’ve discovered It absolutely helpful and it has aided me out loads. I am hoping to contribute & assist different customers like its aided me. Great job.

Definitely, what a splendid blog and enlightening posts, I definitely will bookmark your site.Best Regards!

I will right away grasp your rss as I can’t in finding your email subscription hyperlink or newsletter service. Do you’ve any? Please allow me understand so that I may just subscribe. Thanks.

whoah this blog is great i love reading your articles. Keep up the great work! You know, lots of people are searching around for this info, you could aid them greatly.

This really answered my downside, thank you!

Keep up the superb piece of work, I read few articles on this site and I conceive that your weblog is real interesting and has got bands of great info .

Those are yours alright! . We at least need to get these people stealing images to start blogging! They probably just did a image search and grabbed them. They look good though!

Attractive section of content. I just stumbled upon your website and in accession capital to assert that I acquire in fact enjoyed account your blog posts. Any way I’ll be subscribing to your augment and even I achievement you access consistently rapidly.

Real nice style and design and good written content, nothing at all else we need : D.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

It’s actually a nice and helpful piece of information. I am satisfied that you just shared this useful information with us. Please keep us up to date like this. Thank you for sharing.

I would like to thnkx for the efforts you have put in writing this blog. I am hoping the same high-grade blog post from you in the upcoming as well. In fact your creative writing abilities has inspired me to get my own blog now. Really the blogging is spreading its wings quickly. Your write up is a good example of it.

Enjoyed reading through this, very good stuff, appreciate it.

Yeah bookmaking this wasn’t a speculative determination outstanding post! .

I like what you guys are up also. Such smart work and reporting! Carry on the superb works guys I?¦ve incorporated you guys to my blogroll. I think it’ll improve the value of my website 🙂

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Its like you learn my mind! You seem to grasp so much approximately this, such as you wrote the book in it or something. I think that you just could do with some p.c. to power the message home a bit, however other than that, that is fantastic blog. A great read. I’ll definitely be back.

Currently it appears like Drupal is the preferred blogging platform out there right now. (from what I’ve read) Is that what you are using on your blog?

F*ckin¦ amazing issues here. I am very satisfied to see your post. Thank you so much and i am taking a look ahead to touch you. Will you kindly drop me a mail?

I beloved as much as you’ll receive carried out proper here. The caricature is attractive, your authored subject matter stylish. however, you command get bought an impatience over that you would like be handing over the following. sick indubitably come more previously again since precisely the similar just about a lot often inside of case you defend this increase.

Thanx for the effort, keep up the good work Great work, I am going to start a small Blog Engine course work using your site I hope you enjoy blogging with the popular BlogEngine.net.Thethoughts you express are really awesome. Hope you will right some more posts.

Pretty great post. I just stumbled upon your weblog and wanted to mention that I have truly loved surfing around your blog posts. In any case I’ll be subscribing in your rss feed and I’m hoping you write once more very soon!

I am always invstigating online for articles that can benefit me. Thx!

Hi there, I discovered your site via Google at the same time as searching for a similar matter, your website got here up, it appears to be like good. I’ve bookmarked it in my google bookmarks.

Unquestionably believe that that you said. Your favourite reason appeared to be on the internet the easiest factor to keep in mind of. I say to you, I definitely get irked while folks think about worries that they just don’t recognise about. You managed to hit the nail upon the top as neatly as defined out the whole thing without having side-effects , other people could take a signal. Will likely be again to get more. Thanks

As a Newbie, I am constantly browsing online for articles that can help me. Thank you

Just desire to say your article is as astounding. The clarity in your post is just great and i could assume you are an expert on this subject. Well with your permission let me to grab your RSS feed to keep updated with forthcoming post. Thanks a million and please carry on the rewarding work.

This is a very good tips especially to those new to blogosphere, brief and accurate information… Thanks for sharing this one. A must read article.

You are my aspiration, I possess few blogs and rarely run out from post :). “Actions lie louder than words.” by Carolyn Wells.

Hi just wanted to give you a quick heads up and let you know a few of the images aren’t loading correctly. I’m not sure why but I think its a linking issue. I’ve tried it in two different browsers and both show the same outcome.

Its such as you read my thoughts! You appear to understand a lot approximately this, like you wrote the ebook in it or something. I believe that you just could do with a few p.c. to force the message home a bit, but other than that, that is fantastic blog. A fantastic read. I will certainly be back.

You have mentioned very interesting details! ps nice website.

I always was interested in this subject and stock still am, regards for posting.

I dugg some of you post as I cogitated they were very useful extremely helpful

You made some clear points there. I did a search on the issue and found most people will agree with your website.

You have noted very interesting details! ps nice website . “There’s always one who loves and one who lets himself be loved.” by W. Somerset Maugham.

Keep up the great piece of work, I read few posts on this website and I conceive that your web site is rattling interesting and has got bands of superb information.

Wow that was strange. I just wrote an really long comment but after I clicked submit my comment didn’t appear. Grrrr… well I’m not writing all that over again. Anyway, just wanted to say fantastic blog!

Hey there just wanted to give you a brief heads up and let you know a few of the pictures aren’t loading correctly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same results.

Its great as your other blog posts : D, appreciate it for posting. “History is a pact between the dead, the living, and the yet unborn.” by Edmund Burke.

Virtually all of what you assert happens to be astonishingly legitimate and that makes me ponder why I hadn’t looked at this with this light before. Your article truly did turn the light on for me as far as this particular topic goes. But at this time there is just one point I am not necessarily too comfortable with and whilst I make an effort to reconcile that with the actual core idea of the issue, let me see exactly what all the rest of the readers have to say.Well done.

Its excellent as your other articles : D, regards for putting up.

Well I really liked reading it. This article procured by you is very constructive for proper planning.

Dead indited content material, Really enjoyed reading through.

When I initially commented I clicked the -Notify me when new comments are added- checkbox and now every time a remark is added I get 4 emails with the same comment. Is there any method you possibly can take away me from that service? Thanks!

Merely a smiling visitant here to share the love (:, btw outstanding style and design.

Wonderful blog! I found it while surfing around on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Appreciate it

I besides think hence, perfectly written post! .

Utterly indited written content, regards for information .

What i don’t understood is in reality how you are not really much more neatly-appreciated than you might be now. You are so intelligent. You recognize therefore significantly relating to this topic, produced me personally believe it from so many numerous angles. Its like women and men are not interested unless it is one thing to do with Girl gaga! Your individual stuffs nice. Always handle it up!

It’s the acceptable way to be a heretic, to question the dogma of the day with a joke. — Toni @ Satire.info

I?¦ve read several excellent stuff here. Definitely value bookmarking for revisiting. I wonder how so much attempt you set to make the sort of wonderful informative site.

Thank you for sharing with us, I conceive this website really stands out : D.

I enjoy the efforts you have put in this, thankyou for all the great posts.

I love your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz respond as I’m looking to create my own blog and would like to find out where u got this from. thanks a lot