Ever more sensitive measuring tools are helping to make vehicles – and a lot more – safer for all of us.

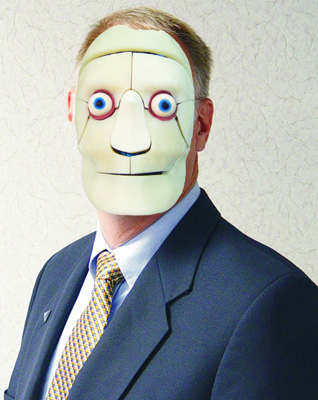

Among those tools is FOCUS (Facial and Ocular CountermeasUre for Safety), a mechanical head developed by Denton ATD in collaboration with Virginia Tech’s Wake Forest Center for Injury Biomechanics and the United States Army Research Laboratory.

FOCUS measures facial effects from airbag impacts, motorcycle and sports injuries. Its sensors measure impact to five facial bones.

Denton’s RibEye, is designed for measurement in another injury-prone area. “With RibEye safety engineers will be able to track up to twelve points in three dimensional space. This is very important to understanding what happens to our ribcage in an automobile accident, in particular side impacts,†said David Stein, president and chief executive officer of Denton Inc, in an earlier AI interview.

Another recent new product is NxT, an in-dummy and in-sensor data acquisition system that allows a higher level of data integrity in crash test dummies and eliminates external wire bundles. Other technologies Denton is working on are advanced sensor technology for measuring shoulder forces from seat belt loading conditions; a lightweight seat belt load cell and an advanced head form assembly with multiple load cells including the eyes. New technology for ATDs include omni-directional necks for child dummies; SID-IIs Side Impact ATD, dummy transport/storage chairs and certification equipment for the ATDs.

“This is an exciting time to be involved in safety testing. More than ever before the consumer is aware of, and making buying decisions based on safety ratings of an automobile,†Stein told Automotive Industries (AI).

AI asked him about the industry’s reaction to FOCUS when it debuted at the SAE World Congress held in Detroit this April.

Stein: It was very positive. There is a lot of interest not only from automotive safety but sport safety as well. In addition to being able to map facial interaction with an automotive interior, FOCUS could also be very useful in evaluating the effectiveness of helmets, goggles, and other types of face guards and shields used in a variety of sports. Some military visitors even suggested we compliment the current sensor package with pressure transducers to measure blast pressure.

AI: Is FOCUS commercially launched or is it still under development?

Stein: We have delivered the first units to the Virgina Tech University. The initial tests went very well. We are quoting the units now with anticipation of being able to begin shipments by the fourth quarter of this year.

AI: How do you think FOCUS will change automotive safety testing?

Stein: Data collected from FOCUS could result in a change of safety technologies (air bag designs) versus a change in safety testing protocols.

AI: Please tell us a little about Denton’s focus on creating a new standard in ATDs?

Stein: For many years the ATD was tasked with helping the engineer detect and quantify gross injuries. That is, those injuries that could cause a fatality. Today, most people are surviving automobile accidents but are sustaining injuries that affect the quality of life. ATDs are now being tasked to measure in ever smaller increments, the degree of injury and they’re not designed for that. The next generation ATD will need to be more biofidelic, more sensitive to a broader range of inputs (lower impacts as well as high), and will most likely include a broader array of instrumentation.

AI: What are some of the new technologies Denton plans to launch over the next year?

Stein: We are introducing new configurations of the RibEye technology. We have added another axis to the measurement system so we can now measure displacement in three dimensions. The first application of this is in the SID IIs side impact ATD. We are also doing a lot of exciting work in the area of materials and modeling.

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks