“Before RibEye, the available devices could only measure rib deflection in one dimension – and with questionable accuracy and reliability†– David Stein, president and chief executive officer of the Denton Companies.

Passenger safety levels are expected by both regulators and customers to increase with each new model – and even during the life of a model. One of the most important tools in establishing the safety of vehicles is crash test dummies.

In this edition, we look at Denton ATD Inc, which was established in July 2000 by Robert A. Denton with the purchase of Applied Safety Technologies Corporation. Denton manufactures a full range of regulated and non-regulated dummies and dummy laboratory certification equipment for the automotive, aerospace and transportation related industries.

Recently, Denton and Kayser-Threde (manufacture of the MicroDAUâ„¢ data acquisition system) – launched NxT which allows a higher level of data integrity in dummies and eliminates external wire bundles. In August this year, Denton launched its RibEye ATD Thorax Displacement Technology that measures linear and oblique rib displacement by using two light angle sensors and light emitting diodes. New products include advanced sensor technology for measuring shoulder forces from seat belt loading conditions; a lightweight seat belt load cell and an advanced head form assembly with multiple load cells including the eyes. New technology for the ATDs include omni-directional necks for child dummies; SID-IIs Side Impact ATD, dummy transport/storage chairs and certification equipment for the ATDs.

Denton recently partnered with TNO Automotive Safety Solutions (TASS) which, the company says, results in the marriage of over 30 years of experience – Denton in crash test dummies and TASS in virtual crash testing. They aim to improve the design, quality and accuracy of ATDs and dummy laboratory certification equipment, and to develop virtual dummies that accurately mimic the behavior of real ATDs.

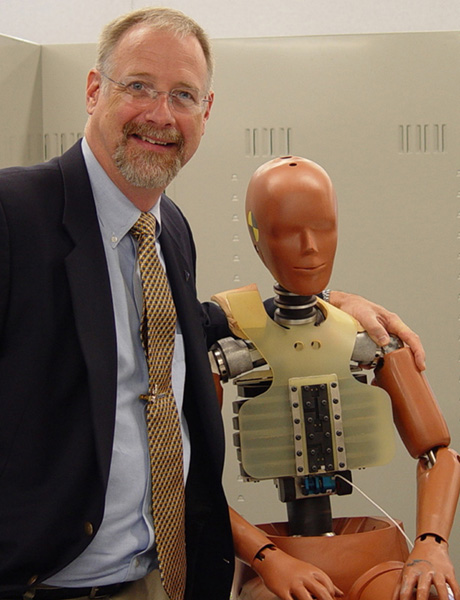

David Stein, president and chief executive officer of the Denton Companies, says his company has been at the forefront of design for a generation.

Stein: Craig Morgan, our Vice Chairman and Vice President of R&D has been designing load cells for the crash environment for over 25 years. He is credited with having designed virtually every load cell used in crash test dummies today.

AI: What is the importance RibEye?

Stein: Before RibEye, the available devices could only measure rib deflection in one dimension – and with questionable accuracy and reliability. With RibEye safety engineers will be able to track up to twelve points in three dimensional space. This is very important to understanding what happens to our ribcage in an automobile accident, in particular side impacts.

AI: What changes are you seeing in the market-place?

Stein: This is an exciting time to be involved in safety testing. More than ever before the consumer is aware of, and making buying decisions based on safety ratings of an automobile. This has been a significant driver in advancing safety research. There is also the continued expansion of the auto manufacturing base as new manufacturers come on line (China for example) and existing manufacturers expand into new markets.

In addition, we are realizing there are many other places we humans are put into harms way where a crash test dummy can save lives. In addition to child seats which have gotten so much attention in recent years, recreational vehicles, motorcycles and the aircraft industries are all are looking at ways to improve the safe use of their products. We are also seeing increased use of dummies in the testing of military vehicles in particular protecting occupants from land mines.

In the early days of crash safety, the dummy’s primary purpose was to save lives. Today we’re doing a very good job of that. Now the dummy is being used to reduce or eliminate injury and this is a very different challenge from just determining survivability of a crash. We will continue to see new technologies, new crash test dummies and test methodologies all leading to safer use of many types of transportation – as I said, this is an exciting time to be involved in safety testing.

More Stories

Shaping the future of the automotive industry at Automechanika Shanghai 2024 with the most fringe programme events and speakers yet

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics