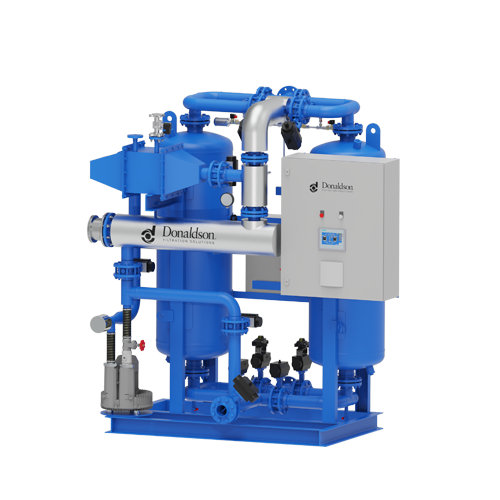

With the updating of its Ultradryer offering to include standard features that were previously optional extras, Donaldson’s new HRE+, HRS+ and HRS-L+ line-up will help to make achieving a stable dewpoint performance for optimised manufacturing operations simpler and more efficient.

Donaldson Ultradryer HRE+ heat regenerated adsorption dryers can be used in all climate zones and provide easy maintenance and low investment costs.

Donaldson has launched a new generation of its popular dryer systems, enhanced to offer many of the optional features of their predecessors as standard, with the aim of boosting reliable performance and energy efficiency. As a key provider of heat regenerative adsorption dryers with the HRS, HRE, HRS-L for the past 30 years, the company was ideally placed to recognise the latest developments customers would require.

“Over the last few years we’ve looked closely at the options that customers invariably add to their order – typically those that supported the requirements for energy-efficient operation – and incorporated them into our standard offering,” explains Wolfgang Bongartz, Industrial Gases Product Manager at Donaldson . “Of course, now there is also a strong demand for connectivity, data transfer and condition monitoring options, so each unit is provided ready for the customer to choose the exact technologies most suitable for their operation.”

The result of this refresh is the HRS+, HRS-L+ and HRE+ product line-up, each available in an extensive range of flow capacities to offer the most efficient match with production facilities.

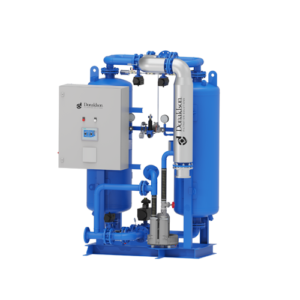

As the most energy-efficient design due to the use of ambient air for desorption and cooling, the 16 models of the HRS+ range are most suitable for operations in more temperate climates. Boasting low operating costs, they use a novel yet proven special desiccant layer to dry the incoming compressed air, while relying on externally heated blower air to aid desorption in the counter-current flow. Should unexpected compressed air or ambient temperature conditions arise, a purge-cooling program can be activated to reduce the dewpoint using compressed air.

Purge cooling is also a feature of the 16-model HRE+ range, which uses both externally heated blower air and 1-2% of the incoming compressed air flow to achieve extremely low dew points, even in tropical climates. Where high ambient temperatures and humidity do not allow for cooling with fresh air, the 12 HRS-L+ models solve the problem by using a water-cooled heat exchanger to cool the air stream heated by the desiccant. When this cooling water is no longer needed, a shut-off valve enables significant savings in water and energy to be achieved. Based on the standard HRS+ range, this closed-loop, zero-purge design can achieve a pressure dew point as low as -70°C, making it ideal for worldwide use.

The Ultradryer HRS+ models are an energy efficient drying solution, providing low operating costs as well as easy maintenance.

Helping to set new standards for efficiency and reliability

With all models now featuring Ultraconomy Dewpoint Control as standard, major energy savings can be achieved by the adsorption cycle time adjusting to current operating conditions, with regeneration only occurring once the desiccant has been fully utilized. ENERSAVE versions of the HRS+ and HRE+ are optionally available for even lower energy consumption.

Safe, reliable performance is helped with a raft of new standard features, such as enhanced monitoring of compressed air system performance, a fan-cooled control box, and the current pressure dewpoint always being visible on the controller display, enabling full controllability of the drying performance.

Along with the pneumatically actuated main valves that provide alarm message indications should a switch-over fail, there are four alarm contacts safeguarding the condition-monitored condensate drains, plus another four customisable individual alarm inputs. Installation costs are reduced by powering those condensate drains from four 230V/AC power supply outputs within the dryer controller, rather than requiring an external power supply, while troubleshooting is simplified through the use of single conductor cable marking. Durability is enhanced with a special painting process that safeguards against corrosion and temperatures as high as 200°C.

The new range of available options now includes two levels of advanced heat insulation, differential pressure monitoring to predict upcoming maintenance while assessing filter and desiccant condition, and flow monitoring with current data indicated on the HMI and long-term data available in graph form. Two new energy management programs are also optional, and a ‘Weekend STOP’ mode enables faster decommissioning for short periods without the risk of pressure loss.

Based on the standard Ultradryer HRS+ models, the Ultradryer HRS-L+ version of heat regenerated adsorption dryers is designed for processing requirements at tropical and subtropical ambient conditions as well as applications with low pressure dewpoint (-70°C) requirements.

Knowledge is power

As a standard feature, the Ethernet Communication Interface is ready for Industry 4.0 and connectivity options. Additional optional data communication modules and protocols, along with data links to user networks will expand the scope for even more efficient operation. Another option, the MMC (MultiMediaCard), ensures dryer uptime by providing back-up memory for the original dryer program in case of issues after reprogramming.

“Of course, Donaldson will always be there to provide extensive application support in these circumstances, whether it’s for troubleshooting or helping with sizing before the unit has even been specified,” concludes Wolfgang. “We can carry out the commissioning, plus handle the maintenance, all thanks to our global presence and regional service organisations.

Compressed air is used in almost all industrial processes, and even a 1°C reduction in its temperature is enough for condensation to begin, resulting in expensive damage and a reduction in quality of the end product. If your application calls for very low residual moisture for pressure dew points below 0°C, then you need an adsorption dryer. And if you are looking for reliability, the lowest pressure dew point and the most energy-efficient way of working, our new generation of Ultradryer should be top of your list!”

To find out more, visit: www.donaldson.com/Ultradryer/

More Stories

Flexible Magna Manufacturing Solutions: The Key to Success in the Automotive Industry

Celanese helping OEMs and Tiers to overcome EV challenges

Automotive Industries (AI) Newsletter October 2024