CHASM Advanced Materials, Inc. (CHASM), a leader in advanced carbon nano

materials technology, has launched NTeCR-E conductive CNT additives for

Li-ion batteries used in electric vehicles (EVs). CHASM will be showcasing

its CNT products and technology as an exhibitor and sponsor at the Advanced

Automotive Battery Conference (AABC) Europe June 19-22 in Mainz, Germany.

Michael Fetcenko, Chairman of CHASM, will also deliver a speech entitled

“Manufacturing Carbon Nanotubes at Gigafactory Scale in the US and Europe”

on June 21, as part of the High-Performance Battery Manufacturing Symposium.

Compared with traditional conductive carbon additives used in Li-ion

batteries, CNTs enable lower internal resistance, increased energy storage

capacity, superior rate capability and longer cycle life. According to a

recent IDTechEx report, the annual demand for CNTs in the Li-ion battery

market is projected to reach 50,000 metric tons by 2032, which is about five

times greater than current global CNT production capacity.

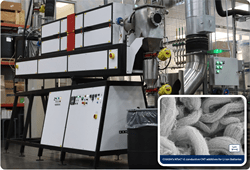

CHASM’s new CNT production platform offers the most scalable, cost-efficient

and sustainable approach for mass production of high-quality CNTs tailored

for Li-ion batteries. The core technologies behind this innovation include

proprietary (iron-free) catalysts plus proprietary (rotary kiln) reactors

for CNT synthesis, which are more capital-efficient than traditional

fluidized bed reactors used by leading CNT producers.

CHASM’s NTeC-E conductive CNT additives are produced at CHASM’s

manufacturing plant in Norman, Oklahoma. CHASM is currently producing its

portfolio of NTeC CNT additives products at pilot-scale (50 metric tons) and

plans to bring online the world’s largest CNT production reactor (1,500

metric tons) during Q4 2024.

CHASM’s NTeC-E conductive CNT additives have been validated by various

partners and independent third-party laboratories through rigorous testing.

These independent test results have consistently shown that NTeC-E

conductive CNT additives perform as well as CNTs made by leading producers

in Asia. Furthermore, test results suggest that NTeC-E conductive CNT

additives are compatible not only with multiple cathode types, but also with

Si-anodes and next-generation solid-state batteries.

In addition, CHASM offers its NTeC-E conductive CNT additives in the form of

dispersions (or conductive pastes) for easy integration with existing

battery industry manufacturing processes. Options include aqueous or

solvent-based, with or without polymer binders. CHASM’s ability to tailor

products for next-generation batteries allows it to meet the evolving needs

of the EV battery industry and remain at the forefront of technology. The

company also designs its CNT production processes to minimize waste and

reduce environmental impact, ensuring both economic and environmental

sustainability.

“As demand for EVs continues to grow, the need for a secure, more

capital-efficient and scalable supply of conductive CNT additives is

becoming increasingly important,” said David Arthur, CEO and Co-Founder of

CHASM. “We’re proud to offer a highly scalable and sustainable solution that

meets the needs of the global EV battery segment.”

The supply of carbon nanotubes holds immense strategic significance for the

Li-ion battery market as automakers build new global battery production

facilities. While most CNT suppliers for EV batteries are currently based in

Asia, CHASM is well positioned to fulfill the crucial local supply

requirements in the U.S. and Europe. CHASM’s business model includes

manufacturing NTeC-E conductive CNT additives and also providing licenses

for strategic partners to mass-produce NTeC-E conductive CNT additives

themselves. To accelerate high-volume scale-up and facilitate global CNT

production, CHASM seeks to collaborate with electric vehicle (EV) battery

manufacturers and key players in the supply chain.

About CHASM Advanced Materials

CHASM’s mission is to develop and manufacture advanced carbon nano

materials, leveraging our innovative product platforms to create a safer,

more connected and sustainable world.

The company’s patented nanotube manufacturing platform combined with its

unique ability to integrate CNTs into product solutions is unleashing the

power of nanotechnology.

Innovations powered by CHASM include universal transparent ADAS heaters for

safer driving, transparent antennas for smarter cities, conductive additives

for EV batteries, and cement additives for greener (lower carbon footprint)

concrete.

For more information, visit http://www.chasmtek.com

More Stories

Mosaic Click board from MIKROE delivers global coverage multi-band and multi-constellation tracking ability

Current transducer from Danisense selected for DC charging station testing device demonstrator at TU Graz

New Click board from MIKROE helps develop and train ML models for vibration analysis