NioCorp Developments Ltd. (“NioCorp” or the “Company”) (NASDAQ:NB) (TSX:NB) today announced its intent to launch a phased approach to commercial-scale production of aluminum-scandium (“Al-Sc”) master alloy in the US for commercial and defense applications. Coupled with the Company’s intended plans to produce more than 100 tonnes per year of scandium oxide from its proposed Elk Creek Critical Minerals Project (the “Elk Creek Project”) in southeast Nebraska, and depending upon the results of the Al-Sc master alloy initiative, receipt of necessary funding and other factors, the initiative could establish the US as a leading producer of scandium, according to NioCorp CEO and Executive Chairman Mark A Smith.

Under an exclusive agreement with Boston-based Nanoscale Powders LLC (“Nanoscale”) the initial work is expected to result in the production of several ingots of Al-Sc master alloy at potentially commercial amounts of scandium content using a proprietary process developed by Nanoscale that increases efficiency and reduces environmental impacts of Al-Sc production over traditional approaches.

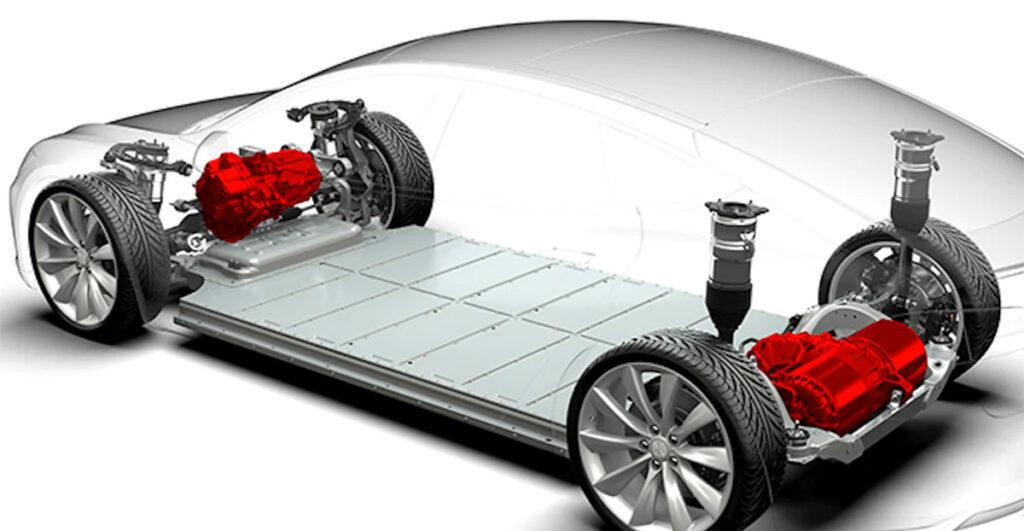

The addition of scandium to aluminum alloys produces a much stronger alloy that reduces weight, improves corrosion resistance, and allows for reliable welding operations. Al-Sc alloy has large emerging applications in automotive and mass transit systems, commercial aviation, space, and defense markets. The traditional method of introducing scandium into Al-Sc alloys is via a master alloy containing 98% aluminum and 2% scandium. NioCorp’s and Nanoscale’s goal is to demonstrate the ability to make Al-Sc master alloy containing up to 5% scandium.

NioCorp and Nanoscale plan to first demonstrate Nanocale’s technology at pilot scale using purchased scandium feedstock. If proven to be technologically and economically feasibile, the goal would be to ramp up commercial production of Al-Sc master alloy prior to the Company’s production of scandium oxide at its planned Elk Creek Project once sufficient financing is obtained to allow the Al-Sc master alloy initiative and the Elk Creek Project to proceed to commercial operation. NioCorp believes that providing commercial and defense markets with Al-Sc master alloy will stimulate increased consumption of scandium, which has long been constrained by a lack of supply outside of China.

“Scandium is a game-changer for electric vehicles, mass transit systems, aerospace and defense platforms, and a host of other technologies needed to reduce the carbon intensity of our economy and our world,” said Mark A. Smith, CEO and Executive Chairman of NioCorp. “With existing and highly regarded producers such as Rio Tinto, NioCorp’s plans to produce more than 100 tonnes per year of scandium oxide and vertically integrating from the mine to the master alloy could enable North America to become a leading scandium producer. I look forward to seeing this initiative move forward and to putting Nebraska and the US in a position of global leadership in the production of scandium and aluminum-scandium alloys.”

“In our view, the key to accelerated market uptake of scandium is to provide reliable supplies of Al-Sc master alloy, particularly in a vertically integrated fashion here in the US,” said Scott Honan, Chief Operating Officer of NioCorp. “We evaluated a range of options, and Nanoscale and its proven technology provided the most robust solution as we explore the possibility of producing Al-Sc master alloy.”

“We look forward to eventually establishing aluminum-scandium master alloy production in the U.S. with NioCorp and ramping up to commercial scale as rapidly as possible,” said Andrew Matheson, CEO and a co-founder of Nanoscale. “The growing recognition of scandium’s remarkable properties as an alloying agent with aluminum presents many exciting opportunities in both commercial and defense markets, and there clearly is strong latent demand for this material.”

ABOUT NIOCORP

NioCorp is developing a critical minerals project in Southeast Nebraska that will produce niobium, scandium, and titanium. The Company also is evaluating the potential to produce several rare earths from the Project. Niobium is used to produce specialty alloys as well as High Strength, Low Alloy (“HSLA”) steel, which is a lighter, stronger steel used in automotive, structural, and pipeline applications. Scandium is a specialty metal that can be combined with Aluminum to make alloys with increased strength and improved corrosion resistance. Scandium is also a critical component of advanced solid oxide fuel cells. Titanium is used in various lightweight alloys and is a key component of pigments used in paper, paint and plastics and is also used for aerospace applications, armor, and medical implants. Magnetic rare earths, such as neodymium, praseodymium, terbium, and dysprosium are critical to the making of Neodymium-Iron-Boron (“NdFeB”) magnets, which are used across a wide variety of defense and civilian applications.

ABOUT NANOSCALE POWDERS LLC

Nanoscale Powders LLC was founded in Boston in 2008 with an initial focus on energy materials, and particularly solar quality silicon (“polysilicon”) for solar electricity applications. Our first reactors produced low boron, low phosphorous, 99.9999% purity silicon metal from standard commercial chemicals. Through several subsequent generations of pilot plant design, we have evolved and broadened our technology, and today can offer a range of metal compositions based on our proprietary and patented processes. We are especially focused on titanium metal, alloys, and intermetallic powders. We have also demonstrated a broad range of refractory metals and alloys, including hafnium and nickel-based powders. In addition, we have produced silicon alloy powders for next-generation lithium ion anode development.

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks