Industry, government and academia are working together in Wales to accelerate development of compound semiconductors through the world’s first dedicated compound semiconductor cluster.

“For high power applications, the advanced performance offered by compound semiconductors make them essential for smaller and lighter components allowing extended ranges for EVs,” says Chris Meadows, director of CSconnected, a trade association for organizations in the sector.

Compound semiconductors are made from two or more elements, whereas silicon conductors are made from a single element. These advanced semiconductors are more power efficient than silicon. They enable high speed and optical communications, which makes them ideal for real-time connected applications, such as machine to machine communication.

Automotive applications include magnetic position sensors for managing ignition timing, cam and crank sensors, wheel speed sensors (for anti-lock brakes and other types of active wheel control), and in brushless electric motors.

“Essentially, automobiles are transforming into mobile computers. Heads-up displays, autonomous driving assistance, sensors, mobile phone and communication integration, and high-performance components are now included in their engines. This is made feasible by compound semiconductors, which are driving automotive improvement through innovation,” says KBV Research in a report on the global compound semiconductor market.

“Although these semiconductors used in automobiles account for a small percentage of total semiconductor production, they are of high value and conform with the stringent technical and quality standards. Application-specific system definitions and manufacturing consistency provide the foundation for a compound semiconductor’s applicability in a motor vehicle application. The bar for quality is really high,” it states.

Welsh expertise in the field is illustrated by global businesses such as IQE, which is leading the way in developing the global market and spearheading the development of epitaxial wafers in Wales.

By establishing clusters of expertise Wales has developed significant capabilities in important economic sectors, including automotive, fintech, renewable energy, cybersecurity, compound semiconductors and high-value manufacturing. Collaborative clusters enable industry, academia and government to co-create high-tech ecosystems, according to Chris Meadows, director of CSconnected, the compound semiconductor cluster.

“Wales identified a gap in the market for this type of semiconductor and has created an ecosystem that allows the sector to thrive. Once you have the critical mass, the infrastructure starts to form that attracts other organizations—and the talent that you want to be part of the ecosystem.”

“Compound semiconductors will enable vast improvements in the performance and efficiency of electric vehicles. The semiconductors will work with new battery and other fuel source technologies to improve this efficiency and help to significantly increase the range of electric vehicles,” he adds.

In 2020, CSconnected received government funding provided through UK Research and Innovation’s flagship Strength in Places Fund (SIPF). The 55-month CSconnected SIPF project has a total value of £43million, supported by £25million of UKRI funds. It builds on Wales’s regional strengths and integrates research excellence with a unique regional supply chain in compound semiconductor manufacturing.

On the research, development and innovation side, Wales has Cardiff University, Swansea University, the Institute for Compound Semiconductors, the Compound Semiconductor Applications Catapult and the Compound Semiconductor Centre (a joint venture between IQE plc and Cardiff University).

For compound semiconductor wafer production, fabrication, packaging and equipment manufacturing it has a range of internationally recognized semiconductor businesses.

AI modelling

An example of the support provided by academia is the development of a more efficient way of modelling and designing power electronic converters using artificial intelligence (AI) by a team of experts from Cardiff University and the Compound Semiconductor Applications (CSA) Catapult. Headquartered in South Wales, the organization focuses on three technology areas: power electronics; RF and microwave; and photonics.

Co-author of the modelling study Dr Wenlong Ming, Senior Lecturer at Cardiff University and Senior Research Fellow at CSA Catapult, said: “accurate and fast transient modelling/simulation approaches are essential to efficiently and to rapidly optimize the performance of wide bandgap power electronics systems. We are delighted to work together with CSA Catapult to address this gap.”

CSA Catapult has also entered into a strategic innovation partnership with Siemens to focus on the development of disruptive power electronics and building advanced skills in the UK. There will be a dedicated Siemens power electronics innovation hub at CSA Catapult to facilitate engagement with the UK power electronics ecosystem such as universities, Catapults, RTOs, industrial partners, start-ups, and grant funding organizations.

Another related project is the £20M ESCAPE consortium which aims to establish a globally unique and cohesive end-to-end supply chain capability for silicon carbide (SiC) power electronics. Consortium partners include such as McLaren Applied, AESIN, Clas-SiC, Compound Semiconductor Applications Catapult, Compound Semiconductor Centre, Exawatt, Lyra Electronics, MaxPower Semiconductor, Microchip Inc, Tribus-D, TPS, and the University of Warwick.

The project will support the drive for electrification in the UK and globally, enabling the transition towards net zero emissions, according to a consortium spokesperson.

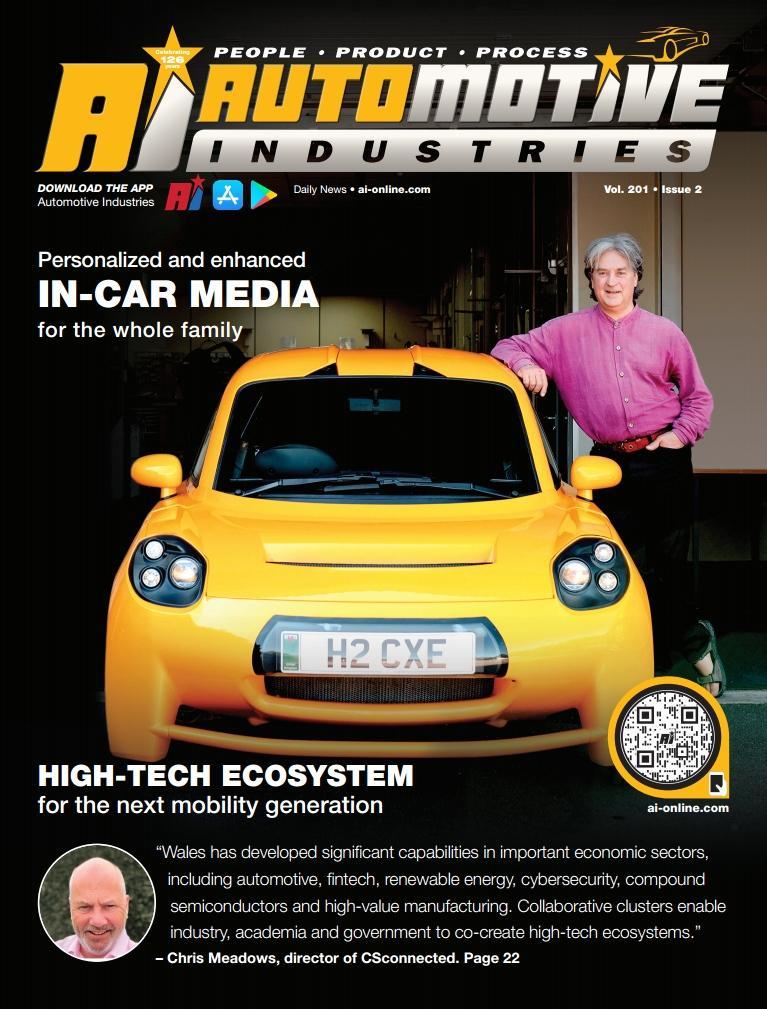

Theory and engineering expertise hit the road at Riversimple, which has spent 20 years developing the technology and business strategies that have led to the construction of a carbon-fiber hydrogen fuel cell-powered Rasa vehicle at its headquarters in the Powys County.

Founder Hugo Spowers is an internal combustion engine convert. “I used to build racing cars – I loved it, but I got out for environmental reasons. We need to move on from

combustion engines. I started looking at all the options – I didn’t even know about hydrogen fuel cells, initially, but when I did, I realized that we needed to build and sell a car in a different way. We sell mobility as a service, much like a mobile phone. You pay a monthly direct debit and that covers all your costs – and when I say all, I really mean it, including insurance and fuel.

“Coming to Wales has been much better than we ever expected. We didn’t realize just what advantages it would have. We get a lot of support from the Welsh Automotive Forum. It’s fantastic for us, being able to leapfrog and establish cross-sectoral collaborations. We’ve also got a fantastic relationship with the Welsh Government, and they really have been extremely supportive. This is a much better environment than if we’d stayed across the border; for what we’re doing, it’s easier to do it here in Wales”.

The Welsh automotive sector in brief

Automotive innovation is steered by the independent Welsh Automotive Forum (WAF), which was established in 2001 to develop a common approach in achieving sustainable continuous improvement for the local industry.

The Board of Directors comprises senior executives from the industry and Robert O’Neil is the Chief Executive. The role of the Welsh Automotive Forum continues to deepen and widen with this transitioning sector and is developing strong links with the UK Government and the Driving the Electric Revolution Team and Compound Semiconductor Applications Catapult

The industry in Wales consists of two niche vehicle makers, about 18 Tier 1’s with the majority international global organizations and an OE Engine Plant, with a further 75 + companies in the service and supply chain, many of which are small and medium enterprises.

In total, some 10,500 people in Wales are directly employed in this sector with other jobs being generated by the multiplier effect.

A success story for Wales has been Toyota’s Deeside plant which open in 1993 and today produces an engine every 44 seconds. It is the first Toyota plant outside of Japan to produce hybrid electric engines which are exported to plants Toyota plants building the C-HR, Corolla and Prius Plus. Building on this, the latest WAF project is to establish Wales as a leader in the electric and hydrogen vehicle supply chains of the future, forming part of the wider Welsh Governments plans to deliver its Net Zero target by 2050.

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks