The automotive industry is focused on achieving success in two major

initiatives. The first is electrification, whereby vehicles are all being

upgraded to electric platforms and powertrains. The other is

‘sensorfication’ – the deployment of an increasing number of sensors on the

vehicle to achieve higher levels of advanced driving assistance systems

(ADAS) for safety and efficiency. These are both areas of significant

investment throughout the automotive supply chain as OEM’s transform their

product lines and business models. However, optical sensors (cameras,

Lidars, infrared cameras) that are exposed to weather or harsh conditions

can fail or go “blind” when contaminants, such as rain or mud, are on the

sensor lens. The operational success of the under ADAS system is dependent

on the sensor, and that system can lose function under these conditions,

threatening the commercial potential and the safe operation of vehicles.

Brooklyn, NY-based start-up Actasys has set out to solve this critical

problem in the automotive and mobility industries as the world gets closer

to AoT (Autonomy of Things). Actasys enables higher levels of assisted

driving and safety for automotive OEM’s and Tier-1’s by ensuring optical

sensor operation under adverse weather conditions.

State of the Industry

The automotive industry has begun to recognize the problem of contaminants

on the sensor lens and its impact on capturing visual data. While these

visions systems can ‘see’ into inclement weather, with varying impacts on

data capture, when there is an obstruction on the lens, it causes a

significant impedance of the vision system. This is a relatively new field

and the industry is starting to starting to coalesce around a series of

basic requirements. Firstly, the cleaning system should not obstruct the

lens, therefore preferring air cleaning over a wiper. Second, there is a

need for three elements: air (rain, light soiling), liquid spray (mud,

splatter), and heat (ice and snow) to address all weather conditions.

Finally, it must be power efficient and easy to integrate, which makes

compressors and blowers as an air source much less appealing.

Who is Actasys and what are their innovations?

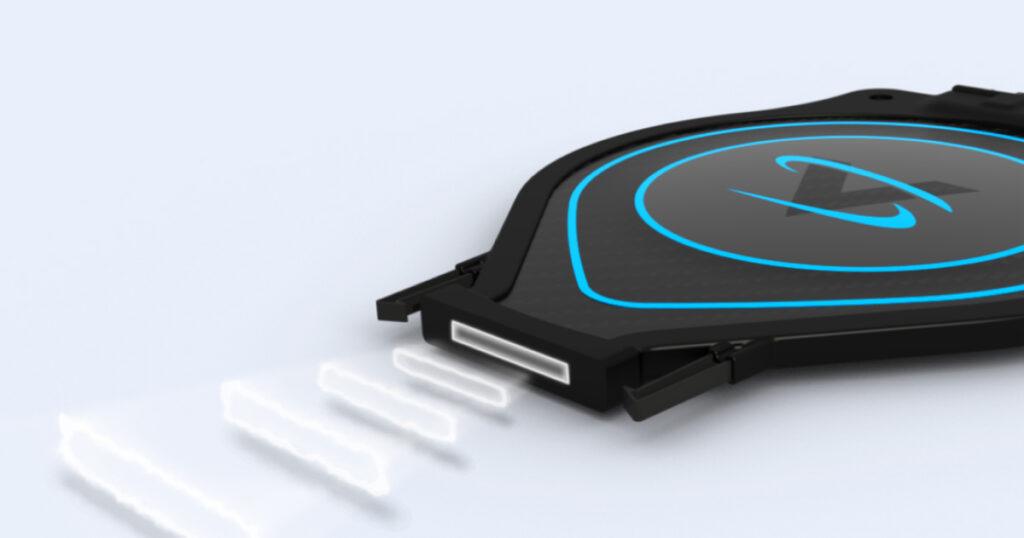

The company’s patented ActaJetT Sensor Cleaning System is an electronically

controlled system of small actuator cartridges that locally generates strong

jets of air to clean and clear sensors without the need for rotary fans,

compressors, or pumps. The air jet can clear the surface of the sensor lens

and is compact, power-efficient, cost-efficient, and effective. The product

was recognized as a CES 2022 Innovation Award Honoree. The air jet from

ActaJet can also be used to generate a liquid spray as well as heated air..

This positions ActaJet as the only sensor cleaning system that can address

the widest range of environmental conditions and meet the key industry

requirements. It is not mechanical, does not interfere with sensor function,

and has a form factor that makes integration easier..

Why is this important?

The estimated market for automotive sensor cleaning through 2030 is over

$80B, including a projected 630M lidar units to be deployed through 2030.

All of these Lidars require sensor cleaning to achieve their technical and

commercial goals. Therefore, the automotive industry plans and success of

ADAS investments are dependent on technologies such as the ActaJetT system

to efficiently enable itto to achieve a transformation of transportation.

As the field of sensor cleaning is still maturing, OEM’s and Tier-1’s

confront a fundamental question: How clean is clean? Removing a contaminant

from the lens of a sensor is one thing. Doing it at 90kph with different

sensor types, different weather and environmental conditions, and different

shapes and aerodynamic effects is another. Actasys recognized that a

product that has a cleaning and clearing function alone is not sufficient.

They have developed a set of methodologies and technologies to assess the

effects of soiling on a sensor and how to then optimize the use of ActaJet

as a cleaning system. This includes analyzing and quantifying what is on the

lens, under what weather and driving conditions, how it affects the sensor,

and how to clear it.

The combination of the ActaJet system and the knowledge capabilities to

analyze the problem places Actasys in a unique leadership position in this

new sector. And ActaJet is not just limited to the automotive sector.

Visual sensors are proliferating and being used in diverse applications such

as security camera systems, smart cities technologies, robotics, defense,

agriculture and other areas. As ActaJet sits at the intersection of sensors

and novel systems, Actasys’ vision is to utilize and expand upon its

capabilities to enable the future potential of vision systems, including

real-time calibration of sensor and ADAS systems, utilization of weather

information, and generation of data around the sensors that can improve

maintenance, use, and optimization. The industry is already recognizing the

advantages of Actasys’ solution and the company is actively engaged in

commercialization with development relationships with several OEM’s and

Tier-1’s. The company is also backed by leading automotive sector investors

the Volvo Cars Tech Fund and NextGear Ventures.

Miles Flamenbaum, CEO of Actasys

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks