Volume Graphics is proud to support Alpine F1® Team as part of a multi-year agreement. Since 2016, the team uses VGSTUDIO MAX for the analysis and visualization of CT data. CT and Volume Graphics have, since then, contributed to a significant increase in the analysis capabilities of Alpine F1 Team’s test laboratory.

“Creating a Level of Confidence That We Perhaps Haven’t Seen Before”

“Personally, the use of Volume Graphics within our department, within the non-destructive testing department, is creating a level of confidence that we perhaps haven’t seen before. It gives you dimensional accuracies, it gives you a greater understanding of the overall part. And with that comes confidence.”

Adrian Talbot, Head of Non-Destructive Testing at Alpine F1 Team

“Racing is the essence of what Volume Graphics stands for: speed, precision, and engineering excellence. Our software is used daily by numerous customers around the world to inspect the most advanced and complex components. But a high-performance sport like this takes us to totally new, previously unknown limits. Overcoming these limits not only helps Alpine F1 Team but all of our other customers.”

Christof Reinhart, CEO Volume Graphics GmbH

“I would recommend Volume Graphics, because it’s quite easy to learn how to use it and it is a software that you can do an incredible number of analyses with.”

Aude Laurence, Material Dr.Eng. & CT Advisor at Alpine F1 Team

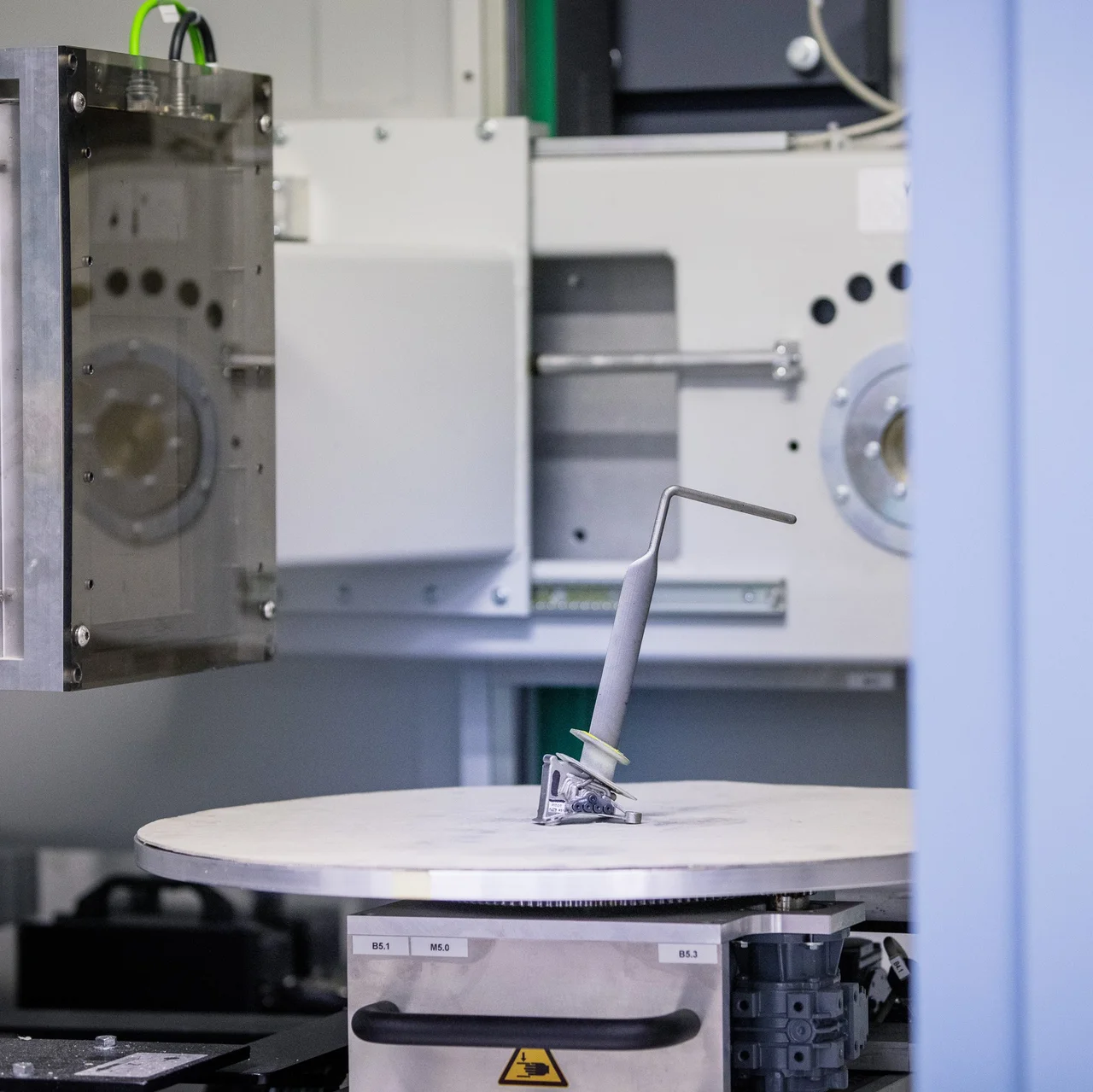

How Alpine F1 Team Uses Volume Graphics

And to do it in the time frame that Volume Graphics allows us to process, is hugely beneficial to our team. With CT and utilizing the Volume Graphics software on a standard assembly, it would take 20 minutes. With the current method, like ultrasound, the whole item could take a day. So, within our non-destructive testing facility, we’ve never had that ability to be able to inspect so many different materials with one method.”

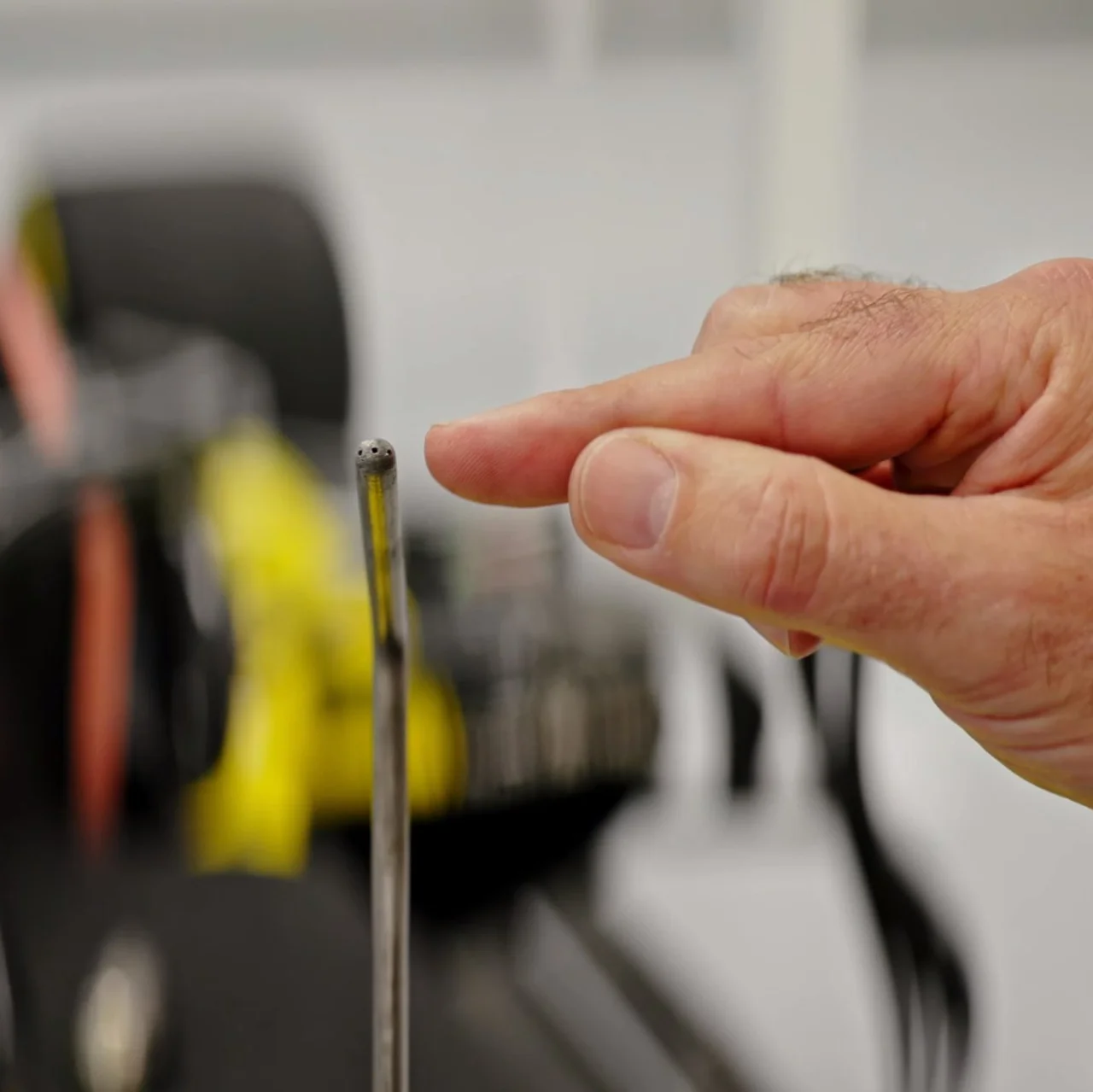

Inside there, there are very, very small holes that assess the pressure, the air pressure, of the car traveling down the main strait of a racetrack. …

… So it’s very important for us to know before this is applied or attached to the car that every channel inside this pitot tube is not blocked, it has good surface finish, and that the general integrity of those tubes are complete and fit for purpose.”

Because we can separate the part digitally, we can essentially cut the part in half without physically having to cut the part in half. …

… And that creates again an enormous amount of feedback to our relevant departments, but also gives us a greater understanding of perhaps why something has failed.”

“I see Volume Graphics software as an extremely useful tool in our toolbox.

It’s clearly going to help us develop our own processes internally and create a more free-flowing, fast-flowing process environment within our non-destructive testing department.”

More Stories

Automotive Industries – The Ultimate Guide: High School Students’ Roadmap to College

Hexagon Purus selected by New Flyer for the fifth consecutive year to supply hydrogen cylinders for transit buses in North America

ROHM Semiconductor and Valeo Co-Develop the Next Generation of Power Electronics