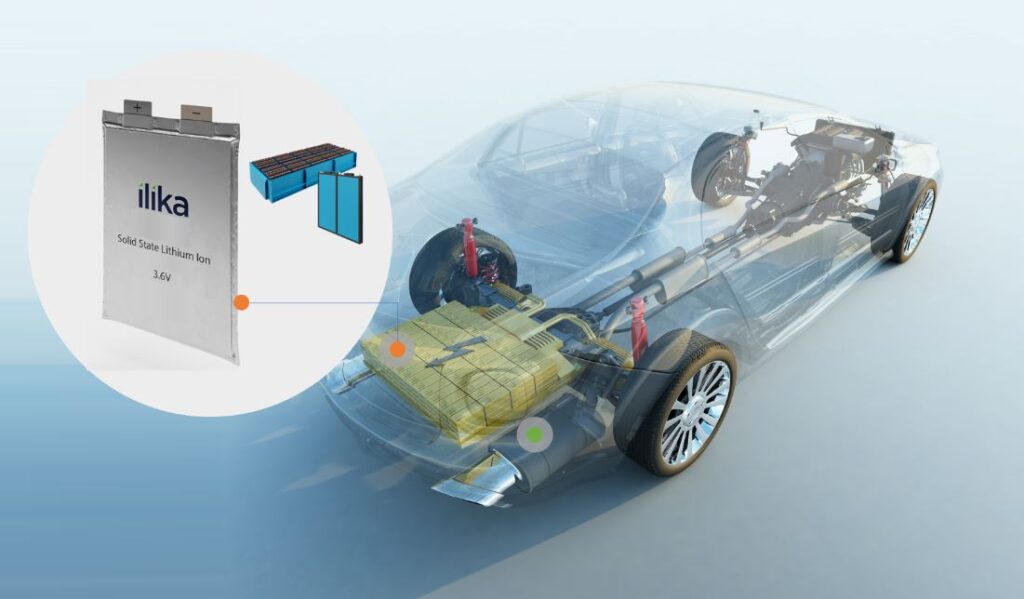

Comau UK and Ilika plc, a pioneer in solid-state battery technology, are

collaborating on a 12-month Advanced Propulsion Centre (APC) funded project,

to design the scale up of Ilika’s lab-based manufacturing capacity. The

initial aim is to increase the production of Ilika’s solid-state battery

cells from 1kWh per week to 10kWh per week at its pilot facility. Comau will

also conduct a feasibility study of the customer’s Goliath solid state

technology process and will design a manufacturing strategy that can be

cost-effectively scaled to reach mass production levels.

The project, which highlights Comau’s continued investments in the

electrification sector, leverages the industrial automation leader’s more

than 45 years of expertise in automation and digitalization technologies. As

Goliath is a next-generation technology, Comau will apply its robust design

capability and battery competencies to propose an innovative solution that

responds to the unique requirements of the project.

Thanks to its facility in the UK, Comau offers the added value of delivering

a seamless, barrier-free, intra-continental customer experience every step

of the way. Furthermore, Comau’s approach to smart automation will allow the

company to select and source the optimal combination of systems that can

meet aggressive throughput and time to market goals. Another important

aspect of the project is its replicability. With Comau’s international

network spanning 14 countries, Comau is able to design a standardized

solution that can be easily reproduced around the world.

“We are honored to be working with Ilika to bridge the gap between prototype

manufacturing and commercial production of next-generation batteries,”

emphasized John Coombes, Managing Director, Comau UK. “Our progressive

approach to simultaneous engineering along with Comau’s cutting-edge

solutions and investments further strengthen our ability to speed

development of promising new technologies.”

Graeme Purdy, CEO of Ilika, added, “Comau is a leader in industrial

automation and plant design with a strong track record in the battery

industry. This project represents an exciting opportunity to work with

Comau’s experts in designing a robust and scalable manufacturing strategy

for our Goliath solid state batteries.”

About Comau

Comau, a member of Stellantis, is a worldwide leader in delivering advanced

industrial automation products and systems. Its portfolio includes

technology and systems for electric, hybrid and traditional vehicle

manufacturing, industrial robots, collaborative and wearable robotics,

autonomous logistics, dedicated machining centers and interconnected digital

services and products able to transmit, elaborate and analyze machine and

process data. With over 45 years of experience and a strong presence within

every major industrial country, Comau is helping manufacturers of all sizes

in almost any industry experience higher quality, increased productivity,

faster time-to-market and lower overall costs. The company’s offering also

extends to project management and consultancy, as well as maintenance and

training for a wide range of industrial segments. Headquartered in Turin,

Italy, Comau has an international network of 7 innovation centers, 5 digital

hubs, 8 manufacturing plants and employs more than 9,000 people in 14

countries. A global network of distributors and partners allows the company

to respond quickly to the needs of customers, no matter where they are

located throughout the world. Through the training activities organized by

its Academy, Comau is also committed to developing the technical and

managerial knowledge necessary for companies to face the challenges and

opportunities of Industry 4.0.

www.comau.com

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks