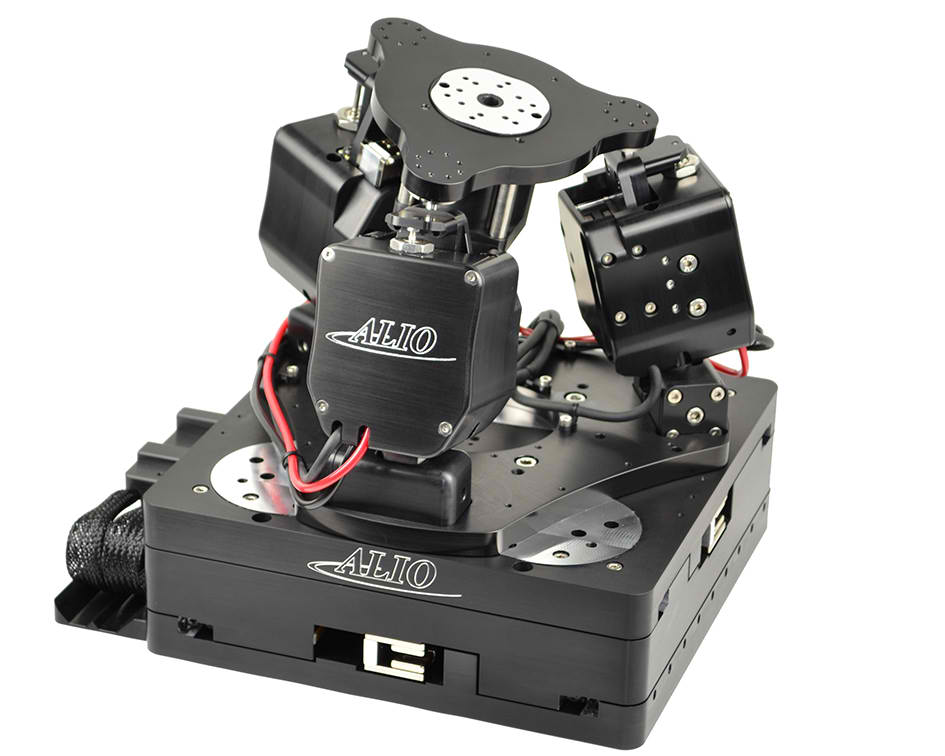

The patented Hybrid Hexapod® was developed by ALIO to address the critical weaknesses of conventional legacy hexapod designs, as well as the weaknesses of stacked serial stages, and to achieve nanometer-level accuracy, repeatability, and high-integrity flatness and straightness during motion. It utilizes a tripod parallel kinematics structure to deliver Z plane and tip/tilt motion, integrated with a monolithic serial kinematic structure for XY motion. A rotary stage integrated into the top of the tripod (or underneath it, depending on application needs) provides 360-degree continuous Theta Z rotation. In this hybrid design, individual axes can be customized to provide travel ranges from millimeters to over one meter, while maintaining nanometer-levels of precision.

However, Bill Hennessey, CEO of ALIO Industries doesn’t look pleased. “I think that maybe the use of the words precision and accuracy by companies working in the motion control sector should be banned. They are meaningless words unless qualified, and even when qualified, can still mean nothing. I see companies claiming, ‘high precision’, ‘best accuracy possible’, ‘ultra precision’. What do these phrases mean to an end-user? How useful are they? Are they just marketing speak, or do they have a currency in industry? Nothing, not at all, and no I’d say!! At ALIO we talk of nanometer-level repeatability, accuracy and precision which actually means something, and as such the use of our motion control solutions in industry grows exponentially.”

The source of Hennessey’s disquiet is that he has positioned ALIO Industries as the world’s only provider of true nanometer-level motion control solutions, and with the Hybrid Hexapod, for example, has developed a technology that exhibits such True Nano Precision® that existing industry validation standards are useless, and a set of new standards based on ALIO’s Point Precision® methodology is being developed by NIST.

“You see, when discussing precision and accuracy, when it comes to motion control there are too many variables that are not fully understood by customers, and which technology suppliers are fully aware of and swerve in their marketing and communications, using data that flatters to deceive, or deceives completely”, Hennessey continues.

“In many ways, the most accurate end of the motion control market is quite a confusing place to be, as the handful of extremely accurate motion systems suppliers tend to use non-consistent and often illusory ways of describing the levels of precision that they can attain. ALIO has always worked in the area of nanometer-level motion control, and as such has a unique perspective on what really works when looking for this level of precision. Because of this, and with the Hybrid Hexapod® very much front and center, we have focussed on educating the customer base to navigate alternative solutions, and give them the tools to interrogate solutions providers in such a way that they can secure a motion control technology suited to their specific applications.

The Hybrid Hexapod had been a game changer for enabling new and novel processes.”

ALIO Industries believes that any claim of precision or accuracy must be first meaningful, and second provable. When looking at motion control solutions such as the Hybrid Hexapod, this is vital, as in common with all hexapods it is a motion control technology that operates with 6 degrees of freedom (DOF), and operates in 3-dimensional space. Because of this the conversation needs to move toward volumetric accuracy.

Despite this, all 6-DOF motion control solutions suppliers are characterised by performance data of a single degree of freedom. This practice leaves error sources unaccounted for in several degrees of freedom, especially in the areas of flatness and straightness, which are critical precision needs at the nanometer-level. The traditional hexapod’s best flatness and straightness of travel is still no more precise than in the order of magnitude of tens of microns per axis.

Because hexapods have six independently controlled links joined together moving a common platform, the motion error of the platform will be a function of the errors of ALL links and joints. Hexapods are known to have optimum accuracy and repeatability when performing Z-axis moves, because all links perform the same motion at the same relative link angle. However, when any other X, Y, pitch, yaw or roll motion is commanded, accuracy and geometric path performance of the hexapod degrades substantially because all links are performing different motions.

It is generally accepted that hexapods have relatively good stiffness compared to serial stacked multi-axis systems. However, it is often only the hexapod’s “Z” (vertical) stiffness that is considered. Geometric design stiffness has a critical impact on and hexapod’s platform repeatability and rigidity. A lack of design stiffness relates directly to a weak XY plane stiffness with the conventional hexapod working platform. Moreover, this inherent design flaw of the conventional hexapod negatively affects XY axis performance, especially with thermal bonding or machining applications that require more force to be performed accurately within the XY plane.

Hennessey continues, “Traditional hexapod providers are aware of these issues, but instead of confronting them, mask the inefficiencies inherent in the system by throwing meaningless precision claims at the situation or not drawing attention to them at all. One for example makes accuracy claims that seem really good, but are in fact impossible to achieve on any 6-link architecture, and above all would be totally out of reach of any customer. The reason for this is that the precision specs that they quote only apply to single axis moves from the center / mid-stroke default position. Who would ever buy a 6 DOF hexapod to only use it one axis at a time at its center of travel? The accuracy as you move to different positions and angles has to degrade probably by multiples of 5x to 10x.”

The Hybrid Hexapod® represents a quantum step forward in motion control, and for the first time provides the ability to achieve repeatable nano-level precision, stimulating innovation and promoting manufacturing efficiency previously considered impossible. It is redefining the area of precision motion control, and the rule book is having to be rewritten to accommodate it and to position it correctly against industry alternatives.

The level of precision achievable with the Hybrid Hexapod renders the vague and illusory industry standard claims of micron and sub-micron precision redundant, and has forced industry to move towards the concept of Point Precision®.

Point Precision® includes all 6 DOF of errors of each axis in motion, guaranteeing the precision point in the full work envelop, and allows for a “precision number” to be quoted based on an exact point on the wall (as if you used a laser pointer) whereas today’s standard only gives the measurement to the wall as if using a flood light. As a signifier of accuracy and precision today, Point Precision® truly is a must for many applications from laser processing to metrology.

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks