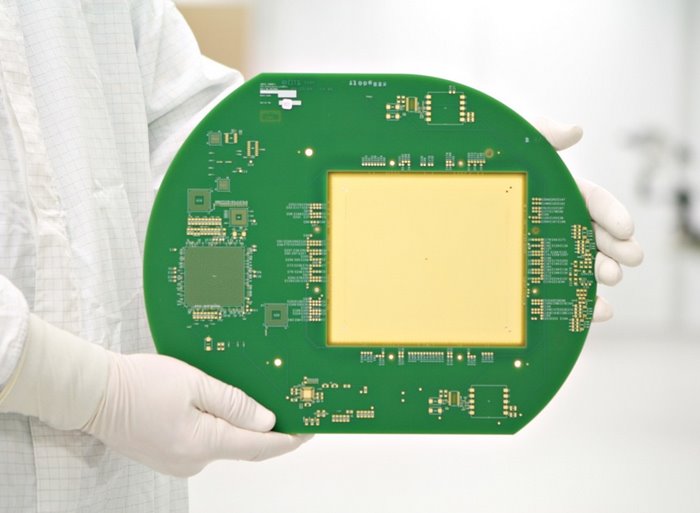

Endicott Interconnect Technologies Fabricates Innovative Set-up PC Board for Space Application

Endicott Interconnect Technologies, Inc. (EI) hasannounced that it has delivered a complex, ruggedized PC board to STI Electronics, Inc. (STI) designed to meet the unique temperature, reliability, performance, vibration and G-force requirements for a space application. EI, with support from STI, developed a unique method of fabricating a double sided PC board with a single tier cavity on a 50 mil copper core. The single tier design allows STI to wire bond their semiconductor module, also fabricated by EI, to the copper core, which in turn provides both heat dissipation and rigidity.

“EI has successfully completed the substrate fabrication of STI’s new IC/DT® prototype using STI’s patented packaging technology Imbedded Component/Die Technology (IC/DT®) and patented design guidelines (US Patent No 7,116,557),” stated Casey Cooper, Electrical Engineering Manager at STI.

“Our engineering and process teams appreciate the opportunity to collaborate on this project. With STI’s assistance, many technical challenges were overcome, allowing us to ship these boards well ahead of schedule and to have passed STI’s assembly test requirements,” commented Ash Bhatt, New Products Program Manager at EI.

“STI is pleased to assist EI with the challenges of multiple cavity/multiple tier designs by sharing our expertise in the successful design and fabrication of similar boards,” stated Mark McMeen, VP of Engineering Services at STI.

About STI Electronics

Since 1982, STI Electronics, Inc. (STI) has been the premier full service organization for training, electronics distribution, consulting, laboratory analysis, prototyping, and small to medium volume PCB assembly in the electronics industry. STI’s Engineering Services division is a multifaceted technical organization whose common goal is to provide engineering support in the field of electronics manufacturing. Utilizing some of the most advanced equipment for R&D, prototyping, and analysis enables engineers and analysts at STI the versatility to provide the highest quality services for a wide range of products in order to address the challenges and issues facing today’s electronic manufacturers. Through product design and manufacturability analysis, to pre-production prototype and development (Engineering Services division is ISO 9001:2008 certified), STI’s Prototype and Development Lab is a full service design review and pre-production facility. As problems arise in the manufacturing process, the Analytical Lab provides a wide range of services designed to characterize materials, detect failure modes, and perform exploratory analysis of products or processes. The Microelectronics Lab consists of over 1000 sq. ft. of ISO Class 6 (Class 1000) cleanroom area for process development and assembly of microelectronic systems, including development of STI’s Imbedded Component/Die Technology (IC/DT®) packaging technology. Additional information may be found by visiting www.stielectronicsinc.com.

More Stories

5 Conclusions One Can Make by Analyzing Car Accident Statistics

Why You Should Invest in Regular Car Washes to Protect Your Investment

Workers’ Compensation for Repetitive Stress Injuries