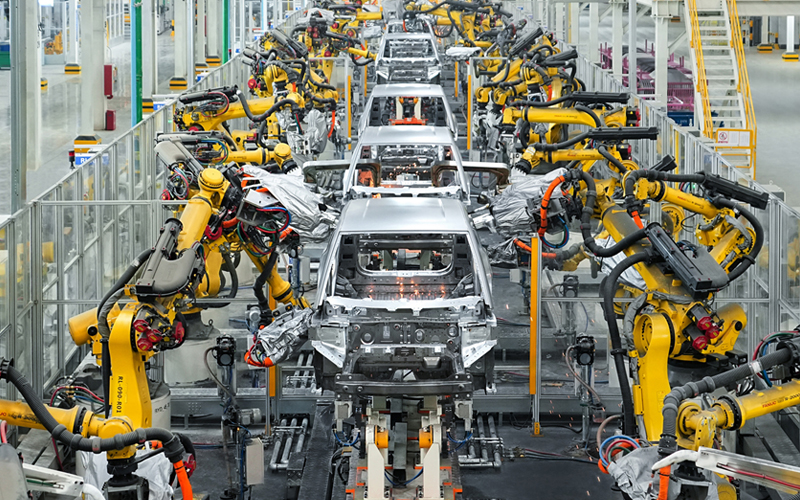

Automation has transformed the automotive industry, making production lines faster, more precise, and less dependent on human intervention. Servo controllers play a crucial role in this transformation, acting as the backbone of robotic motion and precision control systems. Whether in traditional assembly lines or the development of autonomous vehicles, these devices ensure seamless operation, optimizing efficiency and quality in automotive manufacturing.

What Are Servo Controllers and Why Are They Essential in Automotive Production?

Servo controllers are electronic devices that manage the motion of servomechanisms by receiving input signals and sending commands to motors, ensuring accurate positioning, speed, and torque. They are essential in automotive manufacturing because they enable automation with high precision and repeatability, reducing waste and improving product consistency. AMC servo controllers, known for their reliability and advanced motion control capabilities, are widely used in automotive production to optimize efficiency and maintain stringent quality standards.

Key Features of a Servo Controller in Industrial Applications:

- Closed-loop feedback for precise motion control

- Torque and speed regulation to match production demands

- High-resolution encoders for exact positioning

- Programmable control logic for flexible automation

- Integration with industrial networks like EtherCAT and CANopen

- Energy-efficient design to reduce operational costs

How Do Servo Controllers Work in Automotive Manufacturing?

Servo controllers operate based on a closed-loop feedback system, constantly monitoring motor position, speed, and torque to make real-time adjustments. This ensures precise movement, reducing errors and improving efficiency.

Main Components of a Servo Controller:

- Servo motor – Executes the motion commands

- Feedback sensor – Provides position and speed data

- Power supply – Delivers energy for motor operation

- Control circuit – Processes feedback and adjusts motor behavior

- Communication interface – Connects to PLCs or automation networks

Real-World Applications in Automotive Production

- Robotic welding arms that adjust in real-time for optimal weld precision

- Automated painting systems that maintain consistent spray patterns

- Precision CNC machining of engine components for exact fit

- Automated guided vehicles (AGVs) for material transportation

What Are the Main Applications of Servo Controllers in the Automotive Industry?

How Do Servo Controllers Improve Assembly Line Automation?

Servo controllers enable high-speed, precise movements in various manufacturing tasks, ensuring consistent quality and efficiency.

Common Applications:

- Robotic welding – Ensures strong, precise welds with minimal defects

- Automated painting – Delivers even coatings without overspray

- Component assembly – Positions parts accurately for perfect fit

- Material handling – Moves heavy components safely and efficiently

How Do Servo Controllers Enhance CNC Machining and Metal Fabrication?

Servo controllers regulate the motion of cutting tools in CNC machines, ensuring precise drilling, shaping, and milling of automotive parts. Their fast response times help maintain accuracy even in high-speed machining. In the realm of production CNC Machining, servo controllers play a crucial role in optimizing automation, improving repeatability, and ensuring tight tolerances for large-scale manufacturing.

How Are Servo Controllers Used in Robotic Arms?

Robotic arms powered by servo controllers perform essential tasks in automotive plants with precision and repeatability.

Key Functions:

- Material handling – Lifting and positioning components

- Precision joining – Securing parts through welding or fastening

- Assembly assistance – Placing components with high accuracy

- Quality control – Inspecting products for defects

What Role Do Servo Controllers Play in Autonomous Vehicle Production?

Servo controllers contribute to the development of self-driving technology by enhancing sensor calibration, electric steering, and LiDAR stability.

How Do Servo Controllers Optimize Testing and Quality Control in Automotive Manufacturing?

Servo-driven systems automate testing procedures, ensuring vehicles meet strict safety and performance standards.

Applications:

- Stress testing – Evaluating durability under real-world conditions

- Component verification – Ensuring part specifications are met

- Alignment adjustments – Calibrating sensors for autonomous driving

What Are the Different Types of Servo Controllers Used in Automotive Production?

Various types of servo controllers offer different benefits depending on the application.

Analog vs. Digital Servo Controllers

- Analog: Simple, cost-effective, but less precise

- Digital: Higher accuracy, better programmability, and real-time feedback

AC vs. DC Servo Controllers

- AC Servo Controllers: More efficient, suitable for high-speed applications

- DC Servo Controllers: More affordable but limited in performance

Open-Loop vs. Closed-Loop Servo Controllers

- Open-loop: Operates without feedback, leading to lower precision

- Closed-loop: Uses sensors for real-time adjustments, ensuring high accuracy

Integrated vs. Standalone Servo Controllers

- Integrated: Compact design for space-saving installations

- Standalone: More customizable for large-scale automation systems

What Are the Advantages of Using Servo Controllers in Car Manufacturing?

Key Benefits:

- High precision and accuracy – Reduces defects and waste

- Energy efficiency – Lowers operational costs

- Improved production speed – Accelerates manufacturing processes

- Reduced human error – Enhances safety and consistency

- Predictive maintenance capability – Prevents unexpected downtimes

- Integration with IoT and smart factories – Enables Industry 4.0 automation

How Do Servo Controllers Compare to Other Motion Control Technologies?

Comparison with Other Systems:

- Stepper motors: Cost-effective but lack precision and feedback

- Variable frequency drives (VFDs): Good for speed control but limited in torque management

- Hydraulic and pneumatic systems: Strong but less efficient and require more maintenance

What Are the Challenges and Limitations of Using Servo Controllers in Automotive Manufacturing?

Common Challenges:

- High initial cost – Advanced systems require a significant investment

- Complex programming and integration – Requires specialized expertise

- Potential maintenance issues – Sensitive to wear and tear

- Sensitivity to environmental conditions – Performance may be affected by temperature and humidity

How Can Manufacturers Overcome These Challenges?

- Cost reduction strategies – Investing in scalable solutions

- Improved reliability – Regular maintenance and updates

- Training and automation-friendly design – Ensuring workforce adaptation

How Are AI and Machine Learning Enhancing Servo Controllers?

Key Innovations:

- AI-driven predictive maintenance – Reducing downtime with early fault detection

- Real-time adaptive control – Enhancing motion precision through learning algorithms

- Deep learning automation – Improving process optimization in smart factories

How Do AI-Powered Servo Controllers Improve Production Efficiency?

Machine learning models optimize movement patterns, leading to reduced errors and increased throughput.

What Is the Role of Servo Controllers in Smart Factories?

Servo controllers enable Industry 4.0 automation, providing real-time data for better decision-making and efficiency.

Conclusion

Servo controllers are a driving force behind modern automotive production, offering unmatched precision, efficiency, and adaptability. As AI and IoT continue to advance, servo technology will play an even greater role in shaping the future of smart manufacturing. Automakers that leverage servo controllers effectively will remain at the forefront of innovation, ensuring higher quality, safer vehicles, and more sustainable production processes.

More Stories

Tools for Efficient Brake Maintenance

What Makes an Indian Motorcycle Stand Out from the Competition?

Why a Toyota MR2 for Sale is the Perfect Sports Car Choice