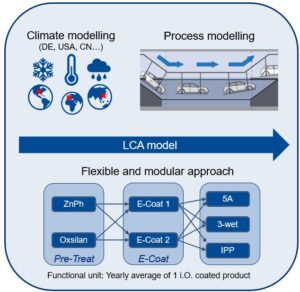

Image: The GLASS tool can be used to analyze the environmental influences of all essential components in the coating process.

In an era where sustainability has become a paramount concern, the automotive industry is under increasing pressure to reduce its ecological footprint and embrace carbon neutrality.

At the same time the industry is facing the challenge of continuously becoming more cost-effective. BASF Coatings’ Global Life Cycle Assessment of Automotive Surface Solutions (GLASS) tool is poised to play a pivotal role in addressing both these challenges.

By providing transparency and actionable insights, GLASS supports car manufacturers on their journey towards sustainable production practices while at the same time enabling them to optimize their operating costs.

The importance of transparency in the paint shop

The automotive paint shop is a critical area of vehicle production, responsible for consuming over 60% of the total energy used in manufacturing. This high energy demand is accompanied by substantial carbon emissions and costs, making the optimization of this phase essential for any comprehensive sustainability strategy.

While the coatings material contributes approximately 30 kg of CO2 per vehicle, the painting process itself can add at least 150 kg of CO2. This significantly impacts the overall carbon footprint of vehicle production, accounting for up to 60% of the total emissions.

Dr. Markus Piepenbrink, Director of Sustainability at BASF Coatings, underscores the importance of this transparency: “Only with comprehensive data and simulation can the OEM in collaboration with us derive impactful measures.”

The GLASS tool fulfills this need by enabling a detailed analysis of both the product carbon footprint (PCF) and the total emissions from the paint shop, including energy consumption and associated costs.

Comprehensive life cycle assessment

GLASS employs an adapted lifecycle analysis model that follows a cradle-to-grave approach, providing a comprehensive overview of the environmental impacts associated with automotive coatings. This methodology encompasses the entire value chain, from raw material extraction to the final clearcoat application, ensuring that all relevant factors are considered.

The GLASS tool allows BASF Coatings and its customers to analyze the environmental impacts of every component involved in the paint application process. This modular approach takes into account regional and site-specific factors, such as local climate conditions, energy use, and customer-specific application processes, ensuring that the analysis is tailored to the unique circumstances of each manufacturer and site.

One of the standout features of GLASS is its flexibility. The tool incorporates over 1,000 parameters across 14 modules, generating more than 75 result charts that provide a detailed view of the ecological footprint associated with various materials and processes.

This depth of detail is crucial for manufacturers seeking to make informed decisions about their production processes.

Enabling informed decision-making

With the insights gained from GLASS, BASF Coatings can empower its customers to make data-driven decisions that foster sustainability. Once the environmental impacts are quantified, BASF can provide targeted advice and develop tailored solutions that meet the specific needs of each customer and individual paint shop.

This may include recommending CO2-reduced technologies that can be implemented at the beginning of the value chain or identifying processes that have a CO2-reducing effect when applied.

Tim Banik, Lifecycle Assessment Expert at BASF Coatings, emphasizes the collaborative nature of this process: “Once transparency is established, we can provide targeted advice to our customers and develop solutions together.”

This approach fosters innovation and strengthens partnerships within the industry, positioning BASF as a leader in sustainability in the coatings sector.

Future directions and broader applications

The positive reception of the GLASS tool in the automotive sector has opened doors for its application in other industries as well. BASF Coatings is committed to expanding GLASS’s reach beyond automotive OEMs, offering its capabilities to various sectors that seek to improve their sustainability practices.

In addition to direct applications, the insights gained from GLASS will inform BASF Coatings’ research and development efforts. Understanding the environmental impact of various processes will help prioritize initiatives that align with carbon reduction goals and drive innovation in product development. As the industry evolves, the tool will continue to serve as a valuable resource for manufacturers striving for a zero-carbon future.

The modular nature of GLASS also allows it to adapt to emerging sustainability trends and regulatory requirements, ensuring that BASF Coatings stays ahead of the curve in a rapidly changing landscape. By integrating new data and methodologies, GLASS can provide ongoing value to customers committed to enhancing their sustainability profiles.

More than an IT product

BASF Coatings’ GLASS tool is more than just an IT product. It represents a transformative solution that empowers automotive manufacturers to take significant strides toward sustainability.

By providing comprehensive transparency and actionable insights, GLASS supports the industry’s transition to carbon neutrality, paving the way for a more sustainable future in automotive coatings.

As manufacturers face increasing regulatory pressures and consumer demand for greener practices, the ability to analyze and optimize their production processes will be crucial. With GLASS, BASF Coatings is not only leading the way in sustainability but is also helping its customers navigate the complexities of the transition to a low-carbon economy.

For more information on GLASS and how BASF Coatings is advancing sustainability, please visit: www.basf-coatings.com/sustainability.

More Stories

6 Common Myths About Motorcycle Accident Claims

Mouser Electronics Paves the Way for Engineers with Online Automotive Resource Center

Barrett-Jackson Kicks Off 2025 with Ultimate Automotive Lifestyle Experience in Scottsdale, Surpassing More Than $198 Million in Total Auction Sales with 100% No Reserve Collector Car Docket