Introduction

In mold manufacturing, quality control (QC) plays a vital role in ensuring the production of robust and plastic molds that meet exact specifications and standards. The intricate nature of mold manufacturing demands attention to every minute aspect to guarantee the production of top-notch components. Overlooking quality control (QC) can have dire consequences, often leading to the production of faulty products due to low quality molds. These defects can range from minor appearance flaws to major functionality failures, posing a risk to user safety. Using low quality molds significantly increases production costs because they require frequent replacements and repairs, and they also result in wastage of raw materials and disruptions in production, ultimately leaving customers unsatisfied.

In this article, we will explore the essential areas of QC, shedding light on the various techniques and best practices that industry leaders employ to guarantee impeccable mold quality.

Importance of Precision and Accuracy

Precision and accuracy are greatly important in mold manufacturing because even the tiniest deviations in the molds can lead to various defects in the final products, making them visually displeasing, not fully functional or completely unusable.

The quality of the molds determine the quality of the final products. Even a small error in the mold’s dimensions can lead to undesirable outcomes such as warping, shrinkage, or uneven surfaces in the end product. For example in medical devices or automotive parts, a minute difference of a millimeter could compromise the integrity and functionality of the components.

Significance of Precision Tools and Equipment:

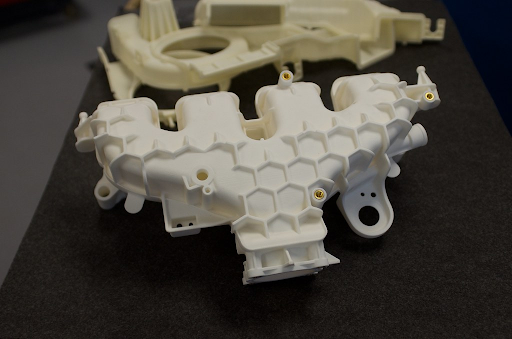

In mold manufacturing the tight tolerances and demanding standards require the use of top-notch precision tools and equipment. These tools include advanced CNC machines and optical sensors that ensure each mold is manufactured with unparalleled accuracy. Without these essential tools, achieving the necessary level of precision would be almost impossible. It’s crucial to understand that the quality, durability, and functionality of the final product heavily rely on the precision of these tools.

Regular Calibration of mold manufacturing instruments

No matter how advanced they are, machinery and instruments can experience wear and tear over time leading to a drift in their accuracy. To ensure optimal performance and consistent results, it is essential to regularly calibrate these devices. By conducting regular checks and making necessary adjustments, the manufacturing process remains consistent, ensuring the integrity of the mold and guaranteeing high-quality end products.

Methods and Techniques for Quality Control

Quality control in mold manufacturing covers a broad spectrum that involves the use of a combination of time-tested techniques and advanced technologies in maintaining the required mold quality. To ensure that molds are reliable and maintain their integrity, manufacturers use both non-destructive and destructive testing methods. They also use software simulation to further enhance the quality control process.

Non-Destructive Testing (NDT):

Visual Inspection: The simplest yet most common method of mold manufacturing quality control involves visually examining molds. During this process, technicians carefully inspect the molds for any external flaws, cracks, or imperfections that could potentially impact mold functionality or product quality.

Ultrasound Testing: This technique uses high-frequency sound waves to penetrate the surface of the mold. By analyzing the reflections of these sound waves, technicians can identify internal defects, voids, or inconsistencies within the material that might not be visible externally.

Radiographic Testing: Radiographic testing, using X-rays or gamma rays, provides a detailed view inside the mold. Similar to a medical X-ray, it identifies internal flaws or discrepancies by analyzing radiation absorption variations in different mold sections.

Destructive Testing:

Despite rendering the test pieces unusable, destructive testing techniques hold great value in providing detailed information about the material properties of the mold. By applying tensile forces, compressive forces, or shear forces to the sample until it fails, technicians can gather crucial data on the mold’s strength, ductility, and elasticity. This data helps in understanding the lifespan of the mold and potential weak points when subjected to operational stress.

Software Simulation:

Software plays a crucial role in ensuring quality control in today’s digital age especially in the manufacture of custom plastic injection molds. Engineers can rely on simulation software to anticipate potential mold defects even before the manufacturing process commences. By inputting specific design parameters, this software simulates real-life scenarios and identifies areas of stress, possible warping, or other structural issues. These proactive measures optimize the design and guarantee precision in the mold, even before its initial prototype is created.

To ensure consistent, efficient, and reliable mold manufacturing, plastic injection molding companies should adopt a holistic approach that combines hands-on testing with digital solutions. This comprehensive quality control strategy guarantees the utmost precision and effectiveness.

Case Studies: Consequences of Neglecting Quality Control

Cases that led recalls and other consequences:

Automotive: In the automotive industry, General Motors (GM), a major automobile manufacturer, faced a significant challenge in 2014. They had to recall over 800,000 vehicles due to ignition switch defects. These flaws were a result of inadequate mold manufacturing quality control. As a consequence, cars would unexpectedly shut off and disable crucial safety features like airbags. This unfortunate situation resulted in severe repercussions, including around 124 fatalities. The company experienced substantial financial losses amounting up to 4.1 billion dollars due to both the costs associated with the recall and the damage it caused to their brand reputation.

Medical Devices: Cardinal Health, a renowned medical plastic injection molding company faced recalls in August, 2020 due to improperly manufactured syringe molds. The syringes had skewed marks that led to the introduction of air in the dose when the plunger was pulled back. This resulted in malfunctioning syringes that occasionally failed to administer the complete drug dose. In a sector where precision is paramount, these oversights led to severe legal repercussions and loss of trust among medical professionals.

Contrast examples with Successful Quality Control:

The aerospace industry is renowned for its unwavering commitment to quality control, which has led to Boeng attributing its exceptional safety record and market dominance. This is achieved through their meticulous mold manufacturing process for aircraft parts and rigorous testing methods for each individual component. By adhering to the industry’s stringent standards, every component is manufactured to meet the required standards. As a result of this dedication to excellence, their aircrafts have superior performance and reliability.

In the electronics industry, Samsung is another example of a global smartphone giant that consistently delivers innovative and reliable devices. This is largely attributed to their robust quality control in mold manufacturing. Their commitment ensures optimal functionality of every component, no matter how small. Such dedication to quality has garnered them customer loyalty and propelled their market success.

Conclusion

In conclusion, it is imperative to uphold the highest standards in this mold manufacturing, since even minor discrepancies can lead to significant failures, including financial setbacks and potential danger to the consumers. As the manufacturing industry advances, there is an increasing need for continuous learning, adopting innovative technology, and regularly conducting audits to ensure smooth operations. It is not only about identifying and rectifying faults but proactively establishing error-free processes from the very beginning. TDL Mold is one company that stands out in quality control expertise. Through their stringent quality control measures and unmatched expertise, they exemplify the ideal approach to mold manufacturing. Their unwavering commitment to quality not only ensures flawless products but also sets a benchmark for the entire mold manufacturing industry.

1 thought on “Quality Control in Mold Manufacturing”