When it comes to maintaining equipment and machinery, cleanliness is crucial for optimal performance and longevity. Many industries rely on efficient cleaning methods to ensure their parts are free from contaminants and debris. But which industries are the most common users of aqueous parts cleaning systems?

Automotive, aerospace, manufacturing, and medical industries primarily use aqueous parts cleaning systems due to their need for thorough, environmentally friendly cleaning processes.

While this brief answer provides a good overview, it’s worth diving deeper into why these industries rely on aqueous parts cleaning systems. Understanding the unique requirements and challenges each sector faces can offer valuable insights into the importance of this cleaning method in various applications.

Why Do These Industries Prefer Aqueous Parts Cleaning Systems?

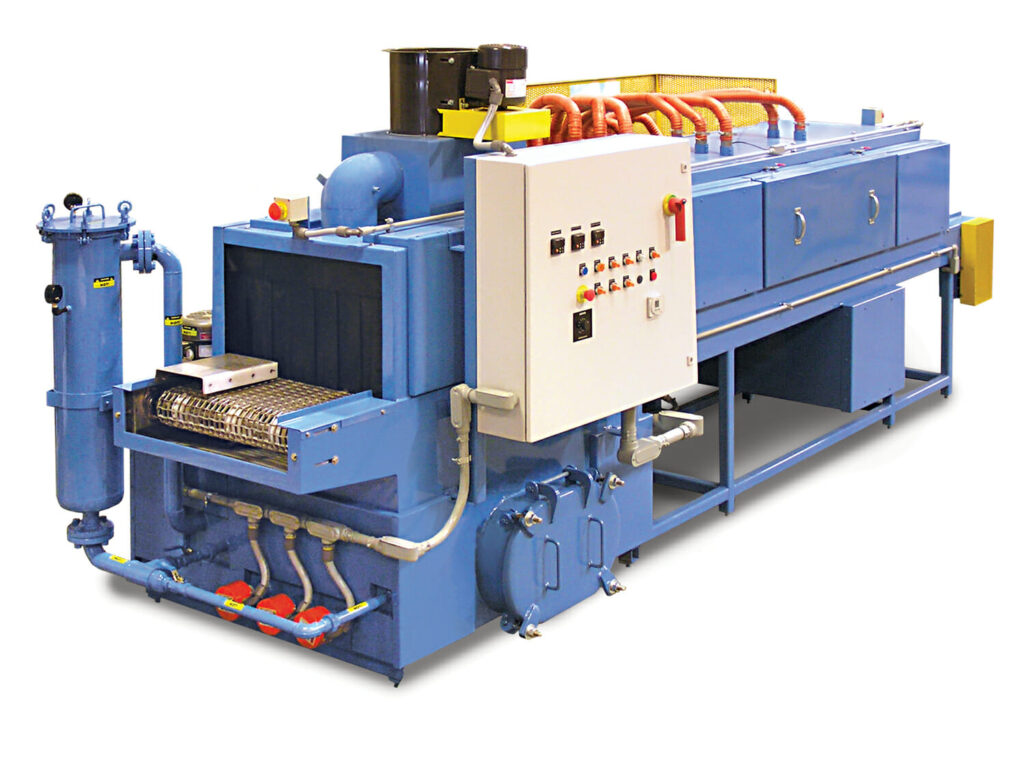

The industries mentioned earlier opt for aqueous parts cleaning systems for several compelling reasons. Industrial parts washers using aqueous cleaning systems have become increasingly popular due to these advantages.”First and foremost, these systems are environmentally friendly, using water-based solutions instead of harsh solvents. This aligns with the growing emphasis on sustainability and reducing environmental impact across all sectors. Industrial parts washers using aqueous cleaning systems have become increasingly popular due to these advantages.

Aqueous cleaning systems are also highly effective at removing many contaminants, including oils, greases, and particulate matter. This versatility is crucial for industries dealing with complex machinery and precision components. Additionally, these systems are generally safer for workers to operate, as they don’t involve hazardous chemicals or emit harmful fumes.

Another significant advantage is the cost-effectiveness of aqueous cleaning systems in the long run. While the initial investment might be higher, they typically have lower operating costs and longer lifespans than solvent-based systems.

What Are The Specific Applications Of Aqueous Cleaning In Different Industries?

In the automotive industry, aqueous parts cleaning systems are used to clean engine components, transmission parts, and various metal surfaces. These systems are particularly effective at removing oil, grease, and carbon deposits that accumulate during vehicle operation.

Aerospace companies utilize aqueous cleaning to maintain aircraft components, including turbine parts and hydraulic systems. The precision required in this industry makes the thorough cleaning provided by aqueous systems essential for safety and performance.

In manufacturing, these systems clean everything from machined parts to electronic components. They’re especially useful in removing cutting fluids, metal chips, and other residues left in manufacturing.

The medical industry relies on aqueous cleaning for sterilizing surgical instruments and cleaning sensitive medical devices. Removing biological contaminants without damaging delicate equipment is crucial in this field.

How Do Aqueous Parts Cleaning Systems Compare To Other Cleaning Methods?

When compared to solvent-based cleaning methods, aqueous systems generally come out on top in terms of environmental impact and worker safety. Solvents can be harmful to both the environment and human health, while aqueous solutions are typically much safer to handle and dispose of.

Regarding cleaning effectiveness, aqueous systems can match or exceed solvent-based methods for many applications. They’re particularly good at removing water-soluble contaminants, common in many industries. However, for some specialized applications involving certain oils or greases, solvent-based cleaning might still be preferred.

Cost-wise, aqueous systems often have a higher upfront cost but lower operating costs over time. They also tend to have longer lifespans and require less frequent replacement of cleaning solutions. This makes them more economical in the long run for many businesses.

It’s worth noting that ultrasonic cleaning, which can be used with aqueous solutions, offers even more powerful cleaning capabilities for certain applications. This combination can be particularly effective for cleaning intricate parts or removing stubborn contaminants.

What Are The Environmental Benefits Of Aqueous Parts Cleaning Systems?

As industries worldwide strive to reduce their environmental footprint, aqueous parts cleaning systems have emerged as an eco-friendly alternative to traditional solvent-based methods. One of the primary environmental benefits is the reduction in volatile organic compound (VOC) emissions. Unlike solvent-based cleaners, aqueous systems produce minimal VOCs, contributing to better air quality inside facilities and surrounding areas.

Another significant advantage is the biodegradability of the cleaning solutions used in aqueous systems. These water-based cleaners are typically formulated with biodegradable surfactants and detergents, which break down naturally over time. This reduces the environmental impact of wastewater disposal and helps companies comply with increasingly stringent environmental regulations.

Aqueous cleaning systems also contribute to water conservation efforts. Many modern systems are designed with closed-loop filtration and recycling capabilities, allowing the cleaning solution to be reused multiple times before disposal. This reduces water consumption and minimizes the volume of wastewater that needs to be treated.

Furthermore, the energy efficiency of aqueous cleaning systems can lead to reduced carbon emissions. Many of these systems operate at lower temperatures than solvent-based cleaners, requiring less energy for heating. Combining with efficient filtration and recycling systems can result in significant energy savings over time.

How Can Businesses Optimize Their Use Of Aqueous Parts Cleaning Systems?

To get the most out of aqueous parts cleaning systems, businesses should focus on several key areas of optimization. First, selecting the right cleaning solution for the specific contaminants and materials being cleaned is crucial. Different industries and applications may require different formulations to achieve optimal results.

Regular cleaning system maintenance is essential for ensuring consistent performance and longevity. This includes monitoring and adjusting water quality, replacing filters as needed, and cleaning the system to prevent contaminants’ buildup. Implementing a scheduled maintenance program can help avoid unexpected downtime and extend the life of the equipment.

Optimizing the cleaning process itself can lead to significant improvements in efficiency. This might involve adjusting factors such as water temperature, agitation levels, and cycle times to achieve the best cleaning results in the shortest time possible. Many modern aqueous cleaning systems come with programmable controls that allow for fine-tuning of these parameters.

Training operators in properly using the equipment is another crucial aspect of optimization. Well-trained staff can identify and resolve issues quickly, operate the system more efficiently, and contribute to maintaining high cleaning standards.

Finally, businesses should consider implementing a waste minimization strategy. This could include recycling cleaning solutions, properly disposing of contaminants, and exploring ways to reduce water consumption. Not only does this approach reduce environmental impact, but it can also lead to significant cost savings over time.

By focusing on these areas of optimization, businesses can maximize the benefits of their aqueous parts cleaning systems, improving cleaning effectiveness while minimizing costs and environmental impact.

Taking the Next Step in Parts Cleaning

Now that you understand the widespread use and benefits of aqueous parts cleaning systems across various industries, it’s time to evaluate your cleaning processes. If you still use solvent-based methods, consider conducting a cost-benefit analysis of switching to an aqueous system. Consider not only the initial investment but also long-term factors like operating costs, environmental impact, and worker safety. This analysis will help you decide whether aqueous parts cleaning is the right choice for your specific needs and industry requirements.

More Stories

Sensor Fusion and the Next Generation of Autonomous Driving Systems

Unique Experiences in Miami: What to Do Off the Beaten Path

The Factors That Impact the Outcome of a Car Accident Claim