Automotive Industries interview with Hideyuki Kurata, the Representative Director, Executive Vice President, CTO of AGC

In this interview with Automotive Industries, Hideyuki Kurata, Chief Technology Officer of AGC, shares insights into the company’s approach to resource allocation, fostering a culture of continuous development, and ambitious technological goals.

Regarding resource allocation, Kurata emphasized the importance of balancing investments in existing business improvements and venturing into new markets. He highlighted the significance of strengthening core capabilities through technologies such as production techniques for quality improvement and cost reduction by utilizing DX. Simultaneously, strategic businesses for the future require a forward-looking perspective, acknowledging that practical applications in the materials industry may take years to materialize.

Kurata discussed AGC’s commitment to continuous development within the organization. He underscored the necessity for engineers to connect with the outside world as technical expertise grows, citing platforms like CES as crucial for discussions on innovation. AGC places importance on sharing the company’s direction, encouraging autonomy, and fostering a flat organizational culture that promotes diversity, equity, and inclusion. This, he believes, is vital for creating an environment where employees can proactively work on tasks and experience personal growth.

Looking toward the future, Kurata expressed his aspirations for AGC to surprise and bring happiness to people through its materials and solutions. He highlighted AGC’s distinctive feature of integrating technology and people, emphasizing the company’s role as a catalyst for innovation. He stressed the importance of diversity and open innovation for seizing opportunities and envisioned AGC as a globally recognized company playing a significant role in the technological landscape by actively engaging in outward-looking initiatives and collaborations with external parties.

Automotive Industries interview with Hideyuki Kurata, the Representative Director, Executive Vice President, CTO of AGC

Automotive Industries: How do you determine the optimal balance between allocating resources for existing business improvement (right-handed) and venturing into new markets (left-handed)?

Kurata: As technologies to strengthen our core capabilities, production techniques that contribute to quality improvement and cost reduction, for example, can be mentioned.

On the other hand, strategic businesses are the ones for the future, so there are many things that are not yet visible. Especially in the materials industry, it is not uncommon for it to take 10, 20, or even 30 years to reach practical application, but we still need to assess and determine our course of action.

Automotive Industries: How does AGC foster a culture that encourages the continuous development of personnel and technologies within the organization?

Given the dynamic nature of technology, how does AGC ensure its workforce remains adaptable and stays ahead of emerging trends in the materials and glass industry?

Kurata: As technical expertise increases, a broader perspective becomes necessary, so it is important for engineers to consciously connect with the outside world , such as experiencing business trends firsthand.

From that perspective, CES is considered one of the most influential technology exhibitions in the world, providing a platform to discuss innovation for creating the future with people from around the globe. It is people who create technology. As individuals and technology develop, the AGC Group will continue to contribute to society.

The AGC Group, with its wide range of business areas and technical foundations, emphasizes the importance of sharing the direction we aim for. This enables each person to act autonomously and challenge with a sense of satisfaction. We will continue to engage in dialogue with employees, striving to create an organization where everyone can proactively work on their tasks and experience personal growth.

To maintain and strengthen the flat culture that the AGC Group has cultivated, we particularly want to actively promote diversity, equity, and inclusion (DE&I). By bringing together different technologies and talents, innovation is born, and encounters between different individuals create the power to generate new value.

Automotive Industries: What are some of the ambitious technological goals that AGC is currently pursuing or planning, and how do these align with addressing complex societal issues?

As the CTO, how do you envision AGC’s role in the global technological landscape in the next decade, and what steps are being taken to maintain and expand its worldwide recognition in technology?

Kurata: When it comes to my aspirations for the future, I want to surprise and bring happiness to people through AGC’s materials and solutions.

This is possible due to the variety of core technologies and processing techniques and adding more value that AGC has cultivated, along with a diverse pool of skilled individuals. Our distinctive feature lies in the integration of technology and people.

We strive to be a group that sparks innovation. Innovation is sparked by chance encounters. To seize those opportunities, diversity, and open innovation (collaboration with external parties) are essential. We aim to be a company that looks outward, closely connected to the outside world.

Automotive Industries also spoke with Onozaki Yu, Automotive Company Mobility Business Development Office Marketing Group Manager and spokesperson for FIR camera compatible windshield at AGC

Automotive Industries: How does the integration of FIR (far infrared) light-transmitting material into windshields contribute to improving nighttime FIR sensor effectiveness?

Yu: By putting the FIR camera behind the wiping area of windshield, it become easy to clean-up the surface of FIR transmitting window, and it improves the effectiveness of FIR sensor.

For example, if FIR camera is putted on the Grill, it is difficult to remove the dirt when the insect hits on the FIR window, and reliability of sensor decreases. But the case of FIR camera-compatible windshield, it is easy to clean-up the surface by wiping.

Automotive Industries: What advantages does placing the FIR camera high inside the windshield offer in terms of sensor fusion and field of view enhancement?

Yu: Recently, most cars have visible light cameras mounted on the upper position of the windshields, but normal glass cannot transmit the FIR ray. So, it is difficult to put the FIR camera nearby the visible light camera with conventional technology.

Our proposal of FIR-camera compatible windshield allows to put the FIR camera nearby the visible light camera, and it improve the feasibility of sensor fusion.

The field of view of Grill-mounted FIR camera is easy to restrict by other objectives like guardrail or other vehicles. But higher mounting position allow to keep field of view under various situation.

Automotive Industries: How is AGC addressing the proposed U.S. Department of Transportation’s new rule for nighttime pedestrian detection with its FIR Camera-compatible Windshield?

Yu: AGC can propose the solutions to OEMs and Tier1s to improve the nighttime pedestrian detection.

AGC believes that our proposal will help the OEMs to address the proposed new rule by NHTSA, and will contribute the reduction of fatal death of pedestrian on nighttime and bad weather conditions.

Automotive Industries asked Nobuoka Kiyoshi, Automotive Company Mobility Business Development Office Project Management Group Senior Manager responsible for AGC’s 5G-compatible Glass Antenna

Automotive Industries: How does AGC’s glass antenna technology contribute to stable connectivity in connected cars, especially in terms of 5G Sub6 compatibility?

Kiyoshi: AGC is proposing a “Distributed Antenna System on Glass”’ that uses the large area of vehicle’s glazing to install the multiple antennas required for 5G communications.

Generally, 5G-sub6 terminals require 4 antennas to perform MIMO communication, and to maximize MIMO communication performance, sufficient distance between each 4 antennas is required. “DAS on Glass”, which places antennas apart from each other on a large glazing, can help maximize MIMO performance theoretically.

In addition, “DAS on Glass” can reduce the probability of communication interruption due to radio wave shadowing caused by surrounding obstacles.

The probability will be improved compared to a roof mount antenna like a fin shape that has 4 antennas integrated into a small housing.

Automotive Industries: Can you share specific use cases or success stories where AGC’s glass antennas have been adopted, such as the collaboration with Halo.Car?

Kiyoshi: So far, the only example of adoption is Halo.Car. However, several car manufacturers are also interested in AGC’s glass antennas.

Automotive Industries: What unique features make AGC’s glass antennas suitable for global LTE and 5G Sub6 frequencies, and how do they contribute to both connectivity and comfort?

Kiyoshi: Of course, our antenna is designed to cover the wide band of LTE and 5G-sub6 from 600MHz to 6GHz.

This is backed on the experience and know-how of planar antenna design for broad cast about 40 years.

Additionally, to improve the freedom of installation location, we also offer a variety of installation methods on glazing, making the antenna transparent is a great feature

But the most important point is that the antenna is designed to meet vehicle glass safety standards.

Regarding comfortability, we are working for developing coexisting technology with antenna and conductive layer. For example, large glass roofs, such as seen in the EVs design trends, use materials such as heat-reflecting glass and light control glass to provide heat insulation.

Since these impede the transmission of radio waves, we are working on the development of technologies to improve the transmission of radio waves and technologies that can be compatible with antenna functions. Such as, the “Wavethru” service in Europe.

Automotive Industries finally asked Kobune Shinji, Automotive Company Mobility Business Development Office Sales Group Manager, AGC, responsible for 3D Curved Cover Glass for Car-mounted Displays. What advantages does AGC’s 3D Curved Cover Glass offer in terms of safety and quality for pillar-to-pillar displays in vehicles?

Shinji: Our strength is HIT management. We have HIT (Head Impact Test) equipment like Tier-1, which allows us to independently verify the glass breaking mechanism. Based on our findings, we provide Tier-1 with our know-how regarding how glass breaks and how to prevent glass breakage. Furthermore, for 3D curved shapes, we utilize the hot bending process, which minimizes residual stress in the glass after bending. As a result, the bonding with the display remains stable.

Automotive Industries: How does AGC manage the entire production process for this technology, from chemically strengthened glass production to decorative printing and composite molding?

Shinji: Our policy is self-made, and we refer to it as “under one roof” or “under one factory.” we can promptly take action for further improvement.

because we utilize our own glass (Dragontrail glass), and our own manufacturing process.

Automotive Industries: Can you share any industry standards or certifications that AGC’s 3D Curved Cover Glass meets, particularly in safety management?

Shinji: We are following the world standard for HIT, (ECE R21 in EU, FMVSS in North America)

In conclusion, the insights shared by Hideyuki Kurata, Chief Technology Officer of AGC, provide a comprehensive understanding of AGC’s strategic approach to resource allocation, continuous development, and ambitious technological goals, aimed at expanding into new divisions and markets. Kurata emphasized the delicate balance between investing in existing business improvements and venturing into new markets, underlining the significance of strengthening core capabilities while maintaining a forward-looking perspective for strategic future endeavors.

AGC’s commitment to continuous development within the organization is highlighted through Kurata’s emphasis on engineers connecting with the outside world and platforms like CES playing a crucial role in fostering discussions on innovation. The company’s focus on sharing its direction, promoting autonomy, and fostering a flat organizational culture that values diversity, equity, and inclusion reflects AGC’s dedication to creating an environment conducive to employee proactivity and personal growth.

Looking ahead, Kurata envisions AGC surprising and bringing happiness to people through its materials and solutions. The integration of technology and people is emphasized as a distinctive feature, positioning AGC as a catalyst for innovation. The importance of diversity and open innovation is underscored for seizing opportunities, with AGC aspiring to be a globally recognized company actively engaged in outward-looking initiatives and collaborations with external parties.

The accompanying interviews with AGC representatives, including Onozaki Yu on FIR camera-compatible windshields, Nobuoka Kiyoshi on 5G-compatible Glass Antenna, and Kobune Shinji on 3D Curved Cover Glass, further highlight AGC’s commitment to innovation across various automotive technologies. From improving nighttime FIR sensor effectiveness to enhancing stable connectivity in connected cars and ensuring safety and quality in pillar-to-pillar displays, AGC demonstrates a holistic and forward-thinking approach to technological advancements.

As AGC positions itself for the next decade, it appears poised to make substantial contributions to the global technological landscape, addressing complex societal issues and actively participating in the evolution of the automotive industry. As for AGC’s brand statement, it states “Your Dreams, Our Challenge”. With a focus on integration, innovation, and collaboration, AGC’s vision aligns with creating a future where technology and people harmoniously coexist to bring about positive and impactful changes.

More Stories

How to Set Up Your Garage with the Right Equipment for Auto Repairs

CarbonX Secures EUR 2.5m European Innovation Council (EIC) Accelerator Grant

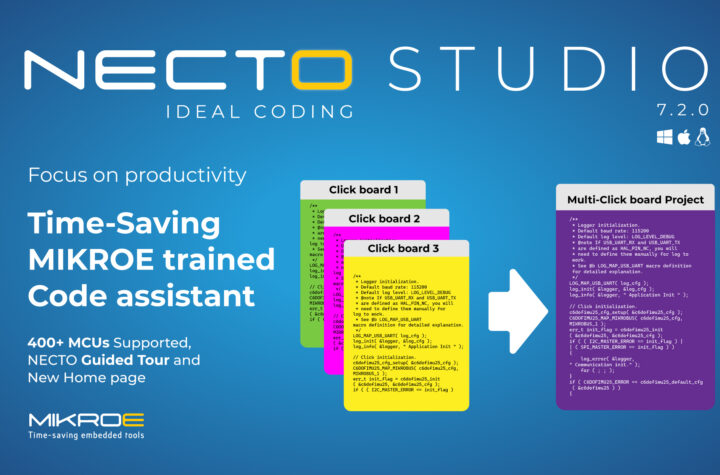

NECTO Studio V7.2 IDE features time-saving, MIKROE-trained Code Assistant for increased productivity