The rapid uptake of electric vehicles is putting pressure on automakers to find alternatives to batteries made with rare earths.

Explore the groundbreaking Clean Earth Magnet® technology in this exclusive interview with Jonathan Rowntree, CEO of Niron Magnetics. Discover how this innovation is reshaping the automotive industry, offering sustainable solutions and superior performance compared to traditional rare earth magnets.

In this conversation with Automotive Industries, Rowntree delves into the proprietary process behind Clean Earth Magnets, highlighting their production from abundant and available materials. These magnets boast comparable performance to traditional counterparts, addressing challenges like rising prices and supply chain instability. Learn how Niron Magnetics is revolutionizing the market dynamics with a sustainable alternative, particularly in the context of increasing demand for electric vehicles and renewable energy technologies.

The interview further explores the environmental impact of Clean Earth Magnets, emphasizing their role in reducing pollution and energy consumption compared to traditional magnets. Rowntree sheds light on the materials science innovation behind iron nitride, explaining how it allows for high magnetization, improved temperature stability, and the use of globally available commodity inputs.

Rowntree discusses Niron’s strategy for addressing potential competition and ensuring pricing stability for Clean Earth Magnets, emphasizing continuous investment in research and development, and strategic partnerships with major automotive manufacturers. The interview also touches upon the significance of showcasing Clean Earth Magnets in consumer devices, highlighting a rare-earth-free speaker exhibited at CES as a milestone for broader technology acceptance.

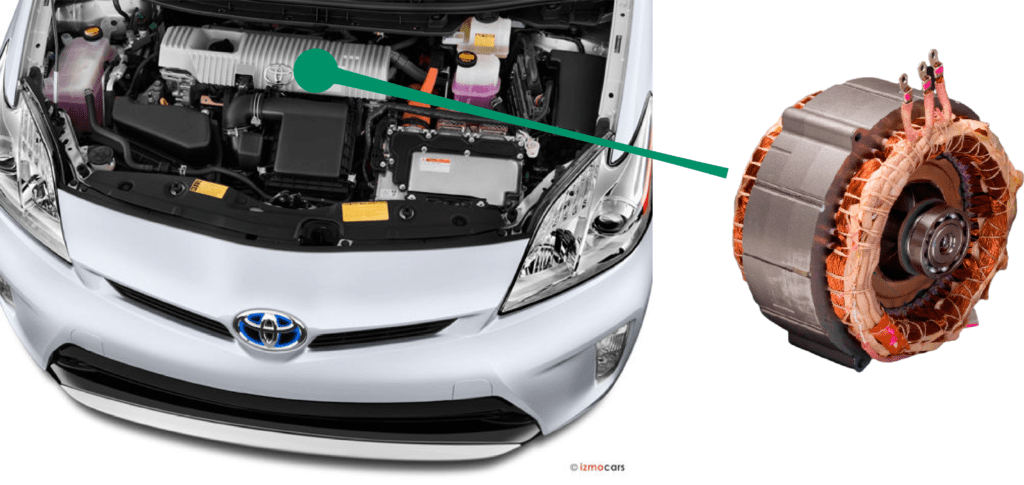

A significant focus is placed on the transformative impact of Clean Earth Magnets in electric traction motors for electric vehicles, where sustainability and cost-effectiveness make them a game-changer. Rowntree provides insights into existing and potential collaborations with automotive manufacturers and suppliers, showcasing partnerships with industry giants like GM, Stellantis, and Volvo Cars Tech Fund.

In conclusion, the interview underscores the transformative shift brought about by Niron Magnetics’ Clean Earth Magnet technology in the automotive industry. Rowntree’s insights reveal a commitment to innovation, sustainability, and strategic partnerships, positioning Clean Earth Magnets as a key player in shaping the future of automotive magnet technology.

Automotive Industries: Overview of Clean Earth Magnet Technology

Automotive Industries: Can you provide an overview of Niron Magnetics’ Clean Earth Magnet technology and how it differs from traditional rare earth magnets?

Rowntree: Niron Magnetics has pioneered a proprietary process for producing iron nitride magnets, eliminating the reliance on rare earth elements like neodymium. The Clean Earth Magnets are created through a specialized nanoparticle production method, offering precise control over size, shape, and composition. These magnets exhibit comparable magnetic properties and performance to traditional rare earth magnets. Unlike their counterparts, Clean Earth Magnets are made from abundant and sustainable materials—iron, nitrogen, and a small amount of carbon, reducing costs and environmental impact.

Advantages Over Traditional Rare Earth Magnets:

Automotive Industries: How does the Clean Earth Magnet address the challenges faced by the automotive industry, particularly with the rising prices and supply chain instability associated with rare earth magnets?

Rowntree: Clean Earth Magnets tackle challenges like rising prices and supply chain instability linked to rare earth magnets. Traditional rare earth magnets, sourced primarily from China, are expensive, difficult to recycle, and face supply chain risks. Niron’s technology relies on abundant and sustainable materials, providing a stable and cost-effective supply chain. Additionally, Clean Earth Magnets offer superior magnetic properties, enabling smaller and lighter electric motors and generators without compromising performance, resulting in cost savings and improved efficiency.

Sustainability and Environmental Impact:

Automotive Industries: Considering environmental concerns, how does the Clean Earth Magnet contribute to sustainability, especially in the context of electric vehicles and automotive components?

Rowntree: Clean Earth Magnets address environmental concerns associated with rare earth magnets. Traditional magnets contribute to water and soil pollution, while their production is energy-intensive. In contrast, iron nitride magnets are made from recyclable and environmentally friendly materials. The production process minimizes waste and energy consumption, improving overall sustainability. By offering a sustainable alternative with superior performance, Clean Earth Magnets reduce the environmental impact of electric vehicles and automotive components.

Impact on Market Dynamics:

Automotive Industries: With 1 in 5 permanent magnets used in automotive applications, how do you foresee the Clean Earth Magnet impacting the market dynamics, especially with the increasing demand for electric vehicles and renewable energy technologies?

Rowntree: Clean Earth Magnets, being rare earth-free, reshape the market dynamics by providing a sustainable alternative. Traditional magnets rely heavily on rare earth elements, leading to supply chain vulnerabilities. Niron’s solution offers competitive performance, especially in electric vehicle motors. The technology enables innovative designs, maximizing stability, efficiency, and allowing compact configurations. As the global shift towards electric vehicles continues, Clean Earth Magnets cater to the growing demand for high-performance magnets, presenting a rare earth-free and environmentally friendly choice.

Materials Science Innovation Behind Iron Nitride:

Automotive Industries: Could you elaborate on the materials science innovation behind Iron Nitride and how it allows for high magnetization, improved temperature stability, and globally available commodity inputs?

Rowntree: The development of iron nitride represents a breakthrough in materials science. Its tetragonal crystal structure allows for strong magnetic interactions, resulting in high magnetization. The unique crystalline structure, particularly in its “alpha double prime” phase, provides high saturation magnetization, generating strong magnetic fields relative to volume. Iron nitride exhibits superior stability across temperatures, making it suitable for automotive applications. Unlike rare-earth magnets, iron nitride uses globally abundant and inexpensive commodity inputs—iron and nitrogen—reducing supply chain vulnerabilities and ensuring stability.

Addressing Competition and Ensuring Pricing Stability:

Automotive Industries: As the demand for magnets in EVs and other applications is projected to increase, how does Niron plan to address potential competition and ensure pricing stability for its Clean Earth Magnet?

Rowntree: Niron’s strategy involves technological innovation and strategic partnerships. Continuous investment in research and development maintains a technological edge, differentiating Clean Earth Magnets and allowing premium pricing. Collaborating with industry players solidifies Niron’s market position and secures long-term contracts, ensuring stable demand and decreasing pricing volatility. Current partnerships with major automotive manufacturers underscore trust in Niron’s technology.

Showcasing Clean Earth Magnet in Consumer Devices:

Automotive Industries: You mentioned showcasing the Clean Earth Magnet in a consumer device. Can you share details on this and how it signifies a milestone for the technology’s broader acceptance?

Rowntree: Niron showcased a rare-earth-free speaker at CES, demonstrating the technology’s real-world applicability. Integrating Clean Earth Magnets into consumer electronics, like the speaker, validates their performance and suitability for various applications. This milestone promotes awareness of sustainable materials, and as consumers prioritize greener alternatives, products featuring rare-earth-free magnets could gain traction.

Transformative Impact in Electric Traction Motors:

Automotive Industries: The list of automotive applications for Clean Earth Magnets is extensive. Could you highlight a specific application where you see the most transformative impact, and why?

Rowntree: The most transformative impact is seen in electric traction motors for EVs. Clean Earth Magnets offer a sustainable and cost-effective alternative to rare earth magnets, reducing reliance on scarce resources and improving scalability in EV production. The technology’s high magnetization and improved temperature stability make it ideal for high-performance electric traction motors, contributing to the growth of the EV market and fostering a more sustainable economy.

Collaborations and Partnerships in the Automotive Industry:

Automotive Industries: Are there any collaborations or partnerships in place or being explored with automotive manufacturers or suppliers to integrate Clean Earth Magnets into their products? How does Niron plan to work with the automotive industry to ensure a smooth transition to this new technology?

Rowntree: Niron actively explores collaborations with automotive manufacturers and suppliers, working closely with key industry players to evaluate Clean Earth Magnets’ performance in various applications. Strategic partnerships with GM, Stellantis, Volvo Cars Tech Fund, and others showcase industry trust. Niron is committed to providing technical support, investing in manufacturing capabilities, and developing sustainable sourcing practices, ensuring a smooth transition for the automotive industry.

Conclusion:

Jonathan Rowntree’s insights into Niron Magnetics’ Clean Earth Magnet technology reveal a transformative shift in the automotive industry. The sustainable and high-performance characteristics of these magnets not only address current challenges but also pave the way for a greener and more efficient future in electric vehicles and renewable energy technologies. Niron’s commitment to innovation and strategic partnerships underscores its role in shaping the future of automotive magnet technology.

More Stories

Marelli focuses on Software-Defined Vehicle evolution at Auto Shanghai 2025, introducing the new ProZone zone control unit

Will Cars Function Like Smartwatches in the Future?

Marelli to Showcase Latest “Speed-to-Market” Innovations at Auto Shanghai 2025