Disruption in the automotive industry: how trikes could replace some cars and motorcycles

Single occupancy vehicle usage is well known. They will not fit all transportation needs. A properly designed and easy to build trike will enable the automotive and motorcycle manufacturers to focus on an efficient production process to capture what has been an underdeveloped market segment.

Having a trike with clean lines on showroom floors will attract consumers, lead to sales and build brand confidence.

The manufacturer will need to refrain from so many gadgets and focus on simplicity to keep the cost low for the consumers. The more complicated the machine is, the more quality control issues consumers will have.

Cars and motorcycles are machines.

All machines perform better and require less maintenance when they use simple mechanical designs and minimal sensors and switches. This is our design philosophy at Tampa Trike (https://tampatrike.com).

We wanted a trike that drives like a traditional four wheel vehicle and the chassis that operates like a traditional motorcycle, but the motorcycle’s big leans take a lot of skill, nerve and can be physically demanding for some riders.

We wanted to capture the best features of both machines. This patented design ( U.S. 11,279,430 and U.S. 11,753,105 Euro and HK patent pending) not only promises an exhilarating drive, but also brings innovation to the forefront of the automotive scene.

Design Set-up

We employed the automotive seating, steering and petal arrangement for comfort. In this setup, the vehicle leaning is controlled autonomously. The low seating position does not allow the driver to lean the vehicle with comfort and consistency. Every corner radius, type of corner at various speeds requires a different lean angle. We developed the autonomous lean control system to work with mother nature to set the appropriate lean angle in real time.

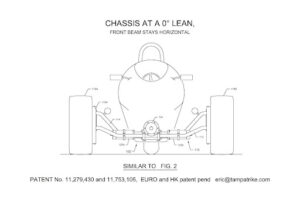

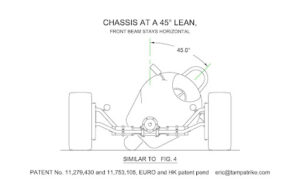

The chassis pivot position delivers unique functionality. The front beam basically always stays parallel with the road surface. The chassis and everything mounted to it and seated in it leans. So almost the entire weight of the vehicle leans into the corner as with a motorcycle. The front beam acts as a constant cantilever. With a manual override, the trike can lean 45 degrees when stationary with no tendency to tip over on its own. The vehicle weight functionally stays inside the triangle.

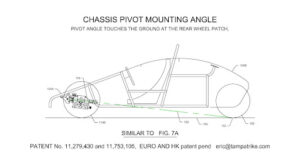

A second functionality is the pivot position inclination, and may be the most unique, is that the angle controls the under and oversteering characteristics of the vehicle. If you draw the chassis pivot center line towards the rear of the vehicle until it touches the road surface, this location sets the under and oversteering characteristic. If this line touches the road surface center of the rear wheel patch, then the chassis steering is neutral. This means that the steering direction of the vehicle set by the steering wheel does not change when leaning into a corner.

If the center line touches in front of the rear wheel patch, the chassis will increase the steering in the same direction of the vehicle lean. If behind the rear wheel patch, the chassis will steer the vehicle in the opposite direction of the vehicle lean.

Adding an actuator could change the under/over steering in real time.

It is a unique feeling when the trike is steady in a corner and simply adding throttle, it will pull tighter into the corner. Our trikes have always done this and I know not to look a gift horse in the mouth. This activity happens simply because the chassis pivot is not parallel with the road surface. The perpendicular of the front beam to the chassis changes like a “little red wagon”. This function is 100% symmetrical. Storyboard 5 on the website shows this chassis function old school style.

In the prototypes we used a single shock / king pin shaft. The production trike has two shock shafts per side. This is done to separate the suspension caster and steering caster. This is used to keep the wide front tires as flat as possible to the road surface. Vehicle lean does not change these settings.

Gear Selection

We believe that our patented chassis design is the future of three wheel vehicles. It has been a lot of work to get it right and we are excited to share it with the world. We also believe there are some innovative people that can take this design up a notch. We are offering our product Patent License Single Vehicle Only so that one can use the patent design as they see fit.

The website https://tampatrike.com, the patent drawings and text contain a buffet of technical information for this trike. We feel the functional issues with a lot of trikes have now been resolved. We also hope the world will appreciate the work and testing that this project required and that they will enjoy the exhilarating ride as I have.

Now that a working arrangement has been documented, this will enable the automotive and motorcycle manufacturers to focus on an efficient production process to capture what has been an underdeveloped market segment.

Having this vehicle on the showroom floors will generate enthusiasm with the sales staff, lead to sales and build brand confidence. The manufacturers should focus on simplicity to keep the cost low for the consumers.

The more complicated the machine is, the more quality control issues consumers will have. Tampa Trike exists to provide consumers with an exhilarating drive, fuel sipping efficiency and salivating to navigate the next tight corner with a big lean.

Opinions for improvements and business inquiries will be warmly welcomed.

More Stories

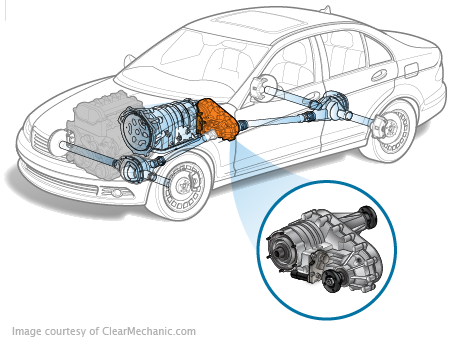

Automating ECU testing for automotive transfer cases using HIL

New LLC Switcher IC From Power Integrations Delivers 1650 W of Continuous Output Power

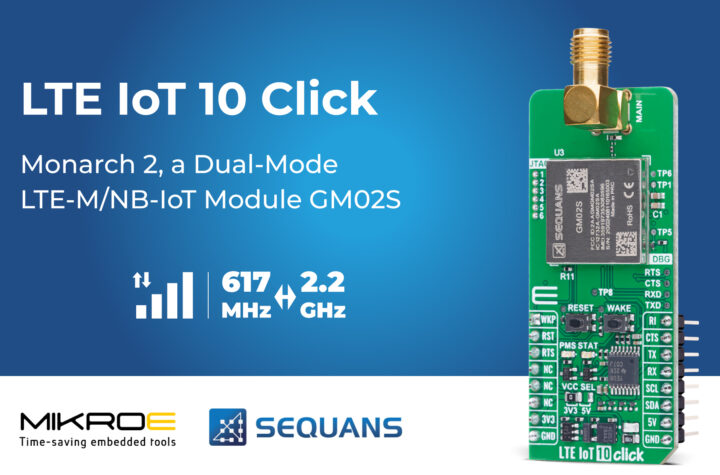

LTE IoT 10 Click Click board from MIKROE provides reliable IoT connectivity