We have been in the automotive engineering space for decades. We have seen product development change over the years. The cliché the rate of change is ever increasing as years go by, and more becomes known. We have written much on various product development and project management topics. The latest through SAE International is Modernining Product Development Processes.

Product Development

Modern product development has many tools and techniques at our fingertips. Simulations have been around for an exceptionally long time. My entire career as an engineer has included many forms of simulation. Still, these tools have evolved to be more capable and appropriate for complex explorations. However, Virtual Reality (VR) and Augmented Reality (AR). These tools can be used throughout product development, including eliciting and evoking product requirements. From experience, understanding and prioritizing product requirements can be difficult, especially when building a product with multiple incarnations and adaptations to meet customer needs across vehicle platforms.

It is probably easy to see how the product matures. The prototype parts throughout the development effort have maturity levels, for example, the first level of prototypes is often a mock-up with no features but an exploration of the physicals, geometries, and dimensional attributes of the product. The next level can be some features and refinement of the physicals, probably of some soft tool. These parts have some level of capabilities, and the customer may be able to use these parts to explore. The product has complete feature content in the last level and is likely off the production tools and processes. There is so much that happens before the customer volume production. [1]

Front Loading

Front loading is a way of investing significant time and resources in the early stages of the development cycle to gauge the readiness and maturity of the technology, typically during the conceptualization phase of a program. Front loading in product development processes aims to reduce r&d cost, improve quality, reduce risk, and accelerate time-to-market.

One of the many ways we can achieve Front loading is by including customer requirements.

Understanding the requirements and desires of the consumer is necessary for market competency. The key questions are which product aspects influence consumer satisfaction and cause discontent. Satisfied customers are often dependable and create a foundation for long-term financial stability. Despite the best efforts of businesses, many NPD initiatives produce goods that fall short of consumer expectations.

As discussed, a thorough understanding of the consumer’s circumstances and the ability to learn and adapt is required. Customers must actively participate in the development activity. The goal of this study was to understand the customer’s needs better. To do this will require customers to be involved in the development of new products. What information do we require from the customer? When (at what stage in the development)

It is common knowledge that customers are a key source of data that helps product developers minimize the risks involved in NPD projects. Several factors contribute to NPD uncertainty, but market and technology are the two biggest. An empirical study revealed that early market and technical uncertainty reduction benefited NPD project success rates. The analysis also showed that market factors, such as client needs, have a more significant impact. According to research, PD initiatives based on well-outlined customer wants (i.e., a market factor) are more likely to be successful than those based on novel technological prospects. [2]

Technology Readiness

We are often not immediately able to press emerging or new technology into our new product development. Technology readiness refers to the level of preparedness of a technology or innovation to be successfully deployed and used in real-world applications. It provides an assessment mechanism to determine a technology’s readiness to meet its users’ needs, perform its intended functions, and operate reliably and safely. This readiness comes with learning, specifically:

• the detail of the technology (physics and working mechanisms)

• can the new technology solve a customer’s need

• how do we apply

TRL is a systematic metric/measuring system that enables assessments of the maturity of a specific technology and the consistent comparison of maturity across other types of technology.

It has evolved and is now used outside of the National Aeronautics and Space Administration (NASA). The Department of Defense (DOD) adopted TRL in 2002, and its versions are used by the Department of Energy and the European Space Agency. A simplified scale is sometimes used for context and explanation:

• Conjecture: This is TRL 1. At this level, hypotheses are formed, and an initial scientific investigation is initiated.

• Speculation: TRL 2 is reached when the basic principles have been well studied and practical applications can be attempted. These applications are speculative because there is little experimental proof of concept for the technology.

• Science: TRL 3 is when active research and design are done. Additional studies are carried out to determine if the technology is viable

.

• Technology: When proof-of-concept models are built and tested, we can move on to TRL 4 where multicomponent parts are tested against each other. This process is called TRL 5 when dashboard technology and simulations in more realistic environments begin. TRL 6 is reached when a fully functional prototype/model is built. For NASA, TRL 7 requires that the prototype/model be tested in the space or airborne environment (whichever is appropriate for the end use of the technology).

• Application: TRL 8 is reached when the technology has been tested and qualified to fly. It is ready to be integrated into an existing technological system and to be implemented. TRL 9 is achieved when the technology has been flight proven during a successful mission. [3]

Manufacturing Readiness

Manufacturing readiness refers to the level of preparedness of a product or technology to be successfully manufactured and produced in large quantities for commercial deployment. It assesses the readiness of a product or technology to be manufactured at scale with high quality, reliability, and efficiency levels.

The MRL is a tool used by the US government to measure the readiness of a plant to manufacture on an assembly line. Each manufacturer reports it to the federal government and helps determine how much government funding can be given to a business for them to become more competitive and efficient.

The MRL measures how prepared a company is for production and how successful it will be at meeting its goals based on what it needs from its facility for it to be productive. The level of MRL can range from 0 to 99, with higher numbers indicating greater readiness and efficiency than lower ones.

As companies start with low levels of MRLs, they may have difficulty receiving funding from the government because there are not enough businesses that meet those levels. However, once they have reached higher levels, they will receive more funding so that they can continue progressing toward becoming more efficient and productive in their facilities while still having room for growth. [4]

Modularity

Modularity is a design approach used in the automotive industry where various components and systems of a vehicle are designed as modules based on their interfaces and requirements for assembly. This allows the manufacturers to integrate them into different vehicle models or variant configurations, reducing the need for unique designs for each vehicle.

One of the significant advantages of modularity is that it allows for greater flexibility in the manufacturing processes. By designing components as separate modules, manufacturers can adjust production volumes of specific features to meet the demand for different vehicle models without disrupting the entire production process.

Modularity reduces product variability by increasing production consistency. The ability to produce more consistent output enhances product performance and may minimize manufacturing costs. By isolating the properties of a product responsible for driving performance into separate modules, modularization makes it possible to break the direct connection between product variation and the expense of complexity. By doing things in this manner, organizations can maximize the number of possible variations for a specific module without creating variations of anything else. Reducing product variability directly impacts various elements of the company’s business, such as improving productivity and reducing labor and expenses.

Modularity increases the profitability of products in many ways. One of the ways is that it reduces time to market, increasing the chances of an organization gaining a competitive advantage. In addition, it reduces the complexity of product offering leading to improvement in the manufacturing processes and product quality.

Additionally, modularity increases product profitability with excellent product performance. Since different consumers measure performance differently, modularity is part of catering to individual customer needs, thus bringing value to the products from every angle.

It is additionally easy to provide product serviceability and faster technological upgrade. However, the most important thing to remember is that modifications made to one product component will only affect specific other components. For instance, this was an essential characteristic for Sony to meet before launching later Walkman versions in the 1980s. Furthermore, modularity makes it simple to produce product designs ready to incorporate cutting-edge components as they become commercially accessible over the product lifetime. [5]

Summary

We can no longer use those product development methods we have in the past, at least not without careful consideration of whether that is appropriate given the circumstances. The 1986 action film Top Gun, the need for speed also applies to product development; quick learning of the technology and the best manufacturing approach requires speed and accuracy. So instead of wire-wrapping prototypes as our first explorations, we have augmented (AR) and virtual reality (VR) to understand the product properties and explore manufacturing approaches. Additionally, artificial intelligence can help explore possibilities; we have used it in a few instances in the service of product development and design alternatives. This tool will only increase competency. We have many tools to speed up our efforts without increasing risks. Product development should not be dogmatic but based upon firm principles and adaptation to meet the objectives.

Bibliography

[1] J. M. Quigley and A. Gulve, “Modernizing Product Development Processes: Guide for Engineers,” Warrendale, PA, Society of Automotive Engineers Publishing, 2023, p. 104.

[2] A. Gulve and J. M. Quigley, “Modernining Product Development Processes: Guide for Engineers,” Warrendale, PA, Society of Automotive Engineers Publishing, 2023, pp. 91-92.

[3] A. Gulve and J. M. Quigley, “Modernizing Product Development Processes: Guide for Engineers,” Warrendale, PA, Society of Automotive Engineers Publishing, 2023, pp. 120-121.

[4] A. Gulve and J. M. Quigley, “Modernizing Product Development Processes: Guide for Engineers,” Warrendale, PA, Society of Automotive Engineers Publishing, 2023, p. 132.

[5] A. Gulve and J. M. Quigley, “Modernizing Product Development Processes: Guide for Engineers,” Warrendale, PA, Society of Automotive Engineers Publishing, 2023, pp. 165-167.

More Stories

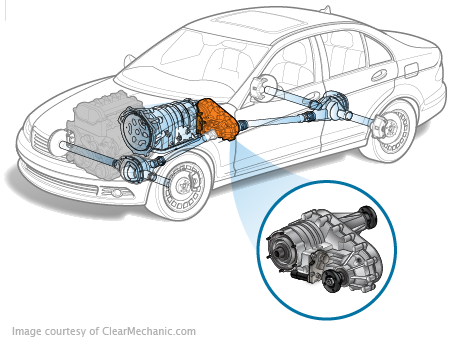

Automating ECU testing for automotive transfer cases using HIL

New LLC Switcher IC From Power Integrations Delivers 1650 W of Continuous Output Power

LTE IoT 10 Click Click board from MIKROE provides reliable IoT connectivity