To learn more about exciting new partnerships and new innovations from Actasys announced at CES 2023 and what it means for the future of transportation, we sat down with Miles Flamenbaum, CEO of Actasys, to ask him a few questions about the announcement and what we can expect to see in the coming years.

Actasys Technology & Innovation Background

* Actasys has broadened the scope of its product, understanding that in automotive sector there is a deep need not just to clean a vision sensor, but to first “detect” the scope and nature of obscuration of that sensor, “correct” the problem by clearing contaminants from the sensor surface, and finally “report” about how the ADAS system and cleaning system are functioning.

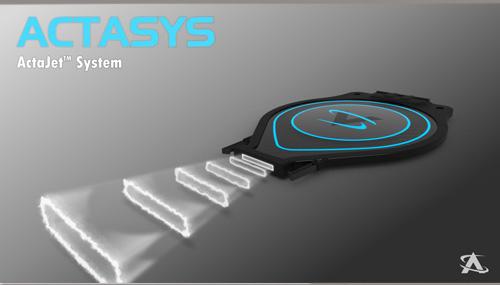

* This means that Actasys’ core hardware, ActaJet, is now surrounded by software and data. Software, based on machine learning algorithms, to detect the problem, hardware to correct the problem, and data analytics to report on the health of the systems.

* The problems addressed by Actasys’ technology are also broader. Ideally, Actasys can enable vision sensors to operate under adverse conditions for any application – Actasys are now engaged in some non-automotive applications such as smart-cities, security cameras, and smart manufacturing.

* Moreover, using the same ActaJet hardware, Actasys can enable the function of electronics as a next generation thermal management solution. Cooling, for the most part, is based on technologies over 100 years old (fans, heat sinks), and is not necessarily efficient nor adaptive.

* ActaJet is a highly efficient, solid-state cooling device. The jet has a unique structure that is very efficient at removing heat.

* Cooling of critical electronics is at the heart the Actasys relationship with Alstom. By improving the capability and efficiency of cooling mission critical control and monitoring systems, Alstom is able to continue to innovate rail transportation and make it more efficient. The future of rail transportation relies on deployment of increasing amounts of advanced electronics. Thermal management of electronics is crucial in this context for increased safety, efficiency, and capability.

Automotive Industries Ai) Interview with Miles Flamenbaum, CEO of Actasys

Ai: Can you explain the significance of Actasys’ technology in the automotive industry and how it differs from other solutions currently on the market?

Flamenbaum: Actasys’ technology is unique in the automotive industry in that it not only cleans vision sensors, but also detects and corrects any issues with obscuration on the sensor surface, and reports on the health of the ADAS system and cleaning system. This is a holistic approach that addresses the entire problem of sensor obscuration, rather than just addressing the symptom of dirty sensors. Additionally, our technology is based on machine learning algorithms and data analytics, which allows for a more efficient and adaptive solution.

Ai: How does Actasys’ technology apply to non-automotive applications such as smart-cities and smart manufacturing?

Flamenbaum: Actasys’ technology can be applied to any application that utilizes vision sensors, regardless of the industry. In smart-cities, for example, our technology can be used to ensure that surveillance cameras are operating at optimal efficiency and providing clear images, even in adverse weather conditions. In smart manufacturing, our technology can be used to ensure that factory automation systems are functioning at their best, even in environments with high levels of dust or other contaminants.

Ai: Can you discuss the significance of Actasys’ technology as a thermal management solution and its impact on industries such as rail transportation?

Flamenbaum: Actasys’ technology, specifically our ActaJet hardware, can be used as a highly efficient and adaptive thermal management solution. Traditional cooling methods, such as fans and heat sinks, are not always efficient or adaptable to the changing needs of modern electronics. Our ActaJet is a solid-state cooling device that is highly efficient at removing heat, which makes it an ideal solution for industries such as rail transportation. By improving the capability and efficiency of cooling mission critical control and monitoring systems, companies like Alstom can continue to innovate and make rail transportation more efficient, safer, and more reliable.

Ai: Can you tell us more about the partnership between Actasys and Alstom, and what inspired the two companies to work together?

Flamenbaum: “Actasys and Alstom have a shared vision of a future where transportation is safer, more efficient, and more accessible to everyone. We both believe that fully autonomous rail systems are the key to achieving that vision, and we recognized that by working together, we could combine our respective expertise and capabilities to make that a reality.

Alstom brings a wealth of experience and knowledge in the rail transportation industry, while Actasys brings advanced technology and innovative solutions. Together, we believe that we can create something truly revolutionary.”

Ai: What specific technologies will be used to make the autonomous rail system a reality?

Flamenbaum: “The autonomous rail system will be powered by a combination of advanced sensors, artificial intelligence, and machine learning. These technologies will enable the system to operate without human intervention, and to adapt to changing conditions in real-time.

For example, the system will be able to detect and respond to obstacles and other hazards, such as broken tracks or equipment failures, and make adjustments to ensure the safety of passengers and crew. Additionally, the system will be able to optimize routes and speeds to increase efficiency and reduce travel time.”

Ai: What are some of the biggest challenges you expect to face in developing this autonomous rail system?

Flamenbaum: “One of the biggest challenges we expect to face is ensuring the safety and reliability of the system. As with any new technology, there will be a learning curve and we will need to ensure that the system is thoroughly tested and validated before it is deployed.

Another challenge will be ensuring that the system is able to adapt to different environments and conditions, such as different weather conditions or different types of terrain. We will need to make sure that the system is able to operate effectively in a wide range of scenarios.”

Ai: Can you tell us more about the announcement Actasys?

Flamenbaum: “At CES 2023, as mentioned, we announced a strategic partnership with Alstom, a leading provider of rail transportation solutions. Together, we will be developing innovative technology to enhance the passenger experience on trains and improve operational efficiency for train operators. This includes the integration of our advanced sensor systems and analytics platform with Alstom’s train control and management systems.”

Ai: How will this partnership with Alstom benefit the rail industry?

Flamenbaum: “This partnership brings together two industry leaders with complementary expertise and technologies. By integrating our advanced sensor systems and analytics platform with Alstom’s train control and management systems, we can provide train operators with real-time insights into the performance and condition of their trains, as well as the passenger experience. This will enable operators to optimize their operations, improve the reliability and safety of their trains, and enhance the overall passenger experience.”

Ai: What are some specific examples of how this technology will be used in the rail industry?

Flamenbaum: “One example is the use of our sensor systems to monitor the condition of trains and predict potential maintenance issues, helping to reduce downtime and improve reliability. Another example is the use of our analytics platform to analyze passenger behavior and preferences, enabling train operators to provide more personalized and efficient services. Additionally, our technology can also be used to improve the energy efficiency of trains, reducing their environmental impact and costs.”

More Stories

Automotive Industries (AI) Newsletter April 2025

Marelli focuses on Software-Defined Vehicle evolution at Auto Shanghai 2025, introducing the new ProZone zone control unit

Will Cars Function Like Smartwatches in the Future?