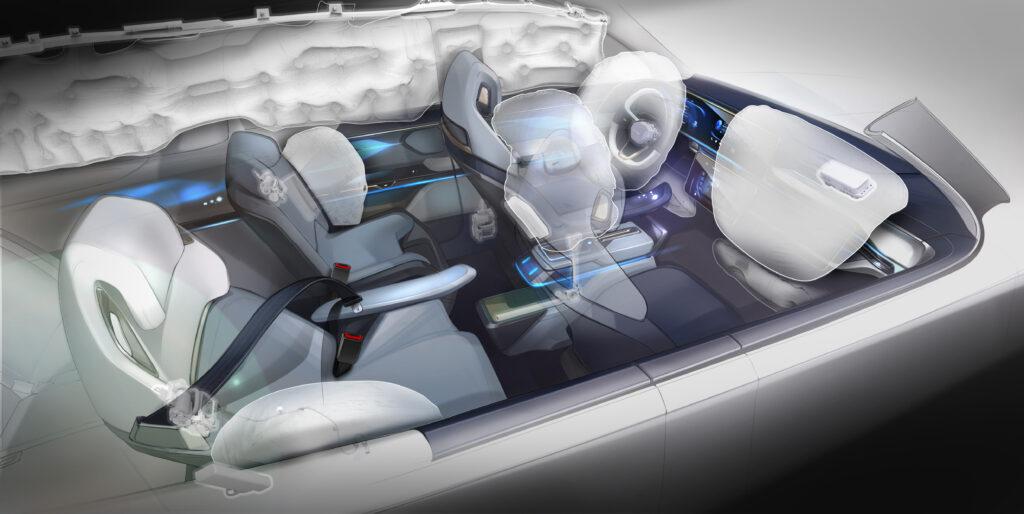

Yanfeng, a leading global automotive supplier, presents a new solution for

integrating the passenger airbag into the instrument panel. This is an

example of the cross-divisional collaboration between the Interior and

Safety Business Units of the company. This new airbag module provides an

integrated safety solution with reduced package size, weight, cost and

improved performance, while at the same time providing greater design

freedom for interior designers and engineers and a leaner manufacturing

process.

Airbag modules integrated into the instrument panel typically use a separate

housing and are installed in many cases at the customer location and

supplied separately from the instrument panel manufacturers creating added

cost and complexity in logistics and testing. Therefore, chute structures,

as part of the instrument panels, and passenger airbag module housings are

developed as separate parts, resulting in an interface that does not reflect

potential synergies very well. The new application combines the airbag chute

and module housing into a single part, reducing weight, package space

consumption and overall system costs. This results in lower energy

requirements to produce the passenger airbag system, as one component is

omitted. The new instrument panel integrated airbag module demonstrates

Yanfeng’s successful commitment in reducing the carbon footprint by 50%.

“This new integration approach is a small but very important step for a more

sustainable future, and improved efficiencies in engineering and

manufacturing costs for both Yanfeng and our customers. Another benefit is

that with our unique safety systems and interiors integration capabilities,

we can leverage synergies and achieve weight savings of up to 23%. We can

offer the new passenger airbag integration for all instrument panels, and in

all vehicle segments,” said Mike Hague, Vice President and General Manager

of Yanfeng Safety Systems in Europe and North America.

Design freedom is another advantage, as the airbag module can adapt to any

instrument panel design. Less space is required due to the removal of

redundant structures, approximately 10-12 mm surrounding the airbag module.

Fewer interfaces thanks to combined manufacturing assembly

In addition to redesigning the airbag-chute/housing of the passenger airbag,

Yanfeng is also optimizing the manufacturing process. The idea is to

integrate the airbag already within the instrument panel production line and

assemble it together with it. This results in a reduction of costs, gains

space and creates synergies in the development process.

In the future, this will enable the customer to procure a pre-assembled

instrument panel with the airbag modules from one single source.

“The improvement of the new solution is that the airbag module is an

integral component of the instrument panel,” explained Hague. “This also

leads to leaner project management between the supplier and the automaker.”

The new instrument panel and passenger airbag integration from Yanfeng is

ready for series production for the next vehicle generation. This product

was recently honored with a 2022 Altair Enlighten Award in the ‘Future of

Lightweighting’ category. This is the industry’s only award dedicated to

vehicle lightweighting.

More Stories

ROHM’s New TVS Diodes: Supporting High-Speed CAN FD In-Vehicle Communication Systems for Autonomous Driving

A Guide to Exploring Different Investment Opportunities

Donaldson brings innovative hydrogen purification solutions to H2Poland 2025