In our previous article we discussed the role and technology of so-called thermal interface materials (TIMs) in battery systems, the development of thermal conductivity in these materials and their supporting role in thermal management, transferring the heat from the battery to the cooling circuit.

Cooling and heating of electrical components in new mobility applications to keep them at optimal operating temperature is extremely critical, ensuring long-lifetime and efficient function. To achieve this, an adequate thermal management system is required. In other words, it is necessary to design a suitable selective thermal management system for the various components used.

If the temperature of a battery is too high this can lead to loss of capacity and in extreme cases to thermal runaway. If the temperature is too low, this can lead to lower efficiency, higher power resistance, decrease of capacity and lithium dendrite formation (lithium plating). Lithium plating can lead to accelerated degradation and failure of a battery cell.

Thermal management aims to ensure optimal temperature in terms of both operation and safety. And to add to the complexity, optimal temperatures for battery systems may change depending on the operation mode. Optimal temperature for the fast charging process may be different from the optimal temperature for driving or parking (storage).

The main types of battery thermal management systems in use today are air cooling, indirect liquid cooling, direct liquid cooling (also known as immersion cooling) and phase change materials. [1]

Cooling system options explained

Air cooling systems are the most widely used as they are simple in design, low cost and have no issues with leakage. Air cooling can be active, via forced convection, or passive due to natural convection. Due to low heat capacity (Cp = 1.006 kJ/kgK at standard temperature) and thermal conductivity compared to e.g. liquid media, air cooling may not be the technology of choice for the next generations of EVs, with larger battery packs and ultrafast charging. [1]

Liquid cooling can be indirect and direct. Cooling liquids compared to air offer higher heat capacity and better thermal conductivity. Indirect liquid cooling is one of the most frequently used solutions in battery thermal management now due to good temperature distribution. The most frequently used coolant is a mixture of water and ethylene glycol. The principle of indirect cooling is based on cooling fluid flowing through channels located at the bottom or side of a battery cell/module, transferring the heat away from the system.

The cooling effect can be improved by the use of so-called thermal interface materials (TIMs). The topic of TIMs, their overview, performance and importance in indirect liquid cooling has been discussed in our previous article . The drawback of indirect liquid cooling lies in the complexity of the system compared to air cooling. A higher number of components and system of channels/pipes can lead to more eventual failures, extra weight and leakage issues.

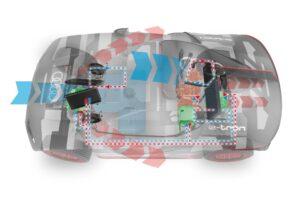

One of the emerging cooling technologies is direct liquid cooling, also called immersion cooling, where the battery is fully immersed in a dielectric fluid. This is an electrically non-conductive liquid with high resistance to electrical breakdown. Advances in this technology mean the complexity of the process and component design could be greatly reduced, contributing also to reduced weight and volume of the circuit and a significant increase in temperature stability and uniformity. Total immersion allows the battery to be heated or cooled as required without heat exchangers, which produces outstanding results in terms of efficiency. Immersion cooling of EV batteries is still considered to be in its infancy, but there are already some use cases available such as the patented fully-submerged battery cell system from Faraday Future [2], the immersion cooling technology in the Dakar Rally car Audi RS Q e-tron [3] or the IMMERSIO™ system from Xing Mobility, founded by Panasonic and Tesla veterans. [4]

Figure 1. Immersion cooling system for the Dakar Rally in the Audi RS Q e-tron [3].

Dielectric fluids normally used in immersion cooling are flame-retardant, which can suppress the thermal runaway event. At present, several cooling media groups are available on the market – hydrofluoroethers, hydrocarbon oils, silicone oils and fluorinated hydrocarbons to name the main options. Increasingly, the focus is turning to biodegradable types of dielectric liquids.

Properties of cooling fluids play a major role in thermal management and should meet several requirements:

– Electrical insulation

– High specific heat capacity and thermal conductivity

– Non-flammability and/or high flash point

– Easily produced, availability in large quantities

– Suitable operating temperature range

– Shelf-life of fluid.

To select a suitable immersion cooling fluid, apart from the above-mentioned requirements, it is essential to consider material compatibility, low density, low viscosity and sustainability.

Cooling fluid options explained

Hydrofluoroethers – coming from power electronics, hydrofluoroethers have gained significant attention in immersion cooling of battery EVs. Literature shows the cooling efficiency compared to air cooled systems is significantly improved. Safety is also improved due to the non-flammability of hydrofluoroethers and due to the virtual absence of flash point. The lifetime performance of these systems still remains to be investigated. Furthermore, density of hydrofluoroethers is approximately 40% higher than of water-glycol systems, which has a detrimental impact on weight and consequently driving range of BEVs. Material cost and disposal of these systems also presents barriers to mass production scale.

Hydrocarbons – these can include mineral oils, poly-alpha-olefins (PAO) and synthetic hydrocarbon oils. Hydrocarbons are products of distillation from petroleum, which makes them low cost, low toxicity, adept for immersion cooling with suitable operating temperature range. A disadvantage of these fluids is that they could be flammable and have flash points.

Esters – this group have seen broad use across industries due to their low cost, high flash points, favorable dielectric properties and ready biodegradability. They are of synthetic or natural origin. Whilst synthetic esters are a product of a chemical reaction between polyol and carboxylic acids, natural esters are a product of vegetable oils. The origin also drives properties of these two groups. Synthetic esters provide good oxidation stability, positively impacting maintenance cycles, but normally have lower flash points compared to natural esters. The shortcoming of ester-based systems is that the cooling capacity decreases with aging as a result of increased viscosity.

Silicone oils – the main benefits of silicon oils lie in good temperature resistance at high and low temperatures and dielectric properties.

Water/glycol – a mixture of water and ethylene glycol. Compared to other systems, water/glycol shows rather high electrical and thermal conductivity and advantageous cost. Due to the conductive nature of the aqueous glycol mixture, its use is limited for indirect cooling. In indirect cooling, the sealing preventing leakage of the mixture onto the battery or wiring is of immense importance, as it prevents short circuit and ultimately thermal runaway. [5]

In summary, thermal management solutions are numerous, and at Datwyler we believe thermal management of battery electric vehicles can be improved by the intelligent use of the right materials and composites. With the mobility sector moving steadfastly towards electrification, the focus now is on supporting manufacturers of cooling liquids, tier suppliers and OEMs, and here Datwyler’s material expertise has been applied at the highest level. Chemical compatibility is key in terms of direct immersion, as sealing solutions can vary depending on the cooling fluid used.

It is imperative to test in order to select the optimal sealing solution for each immersion cooling system. In terms of e-mobility, perfluoropolyethers (PFPEs) seem to be at the forefront due to their characteristic of being inflammable and showing low viscosity levels. But whichever is used in terms of e-mobility it is vital to ensure the sealing solution is compatible to avoid corrosion/degradation in these harsh environments over time and prevent the issues this would bring as a result. [1]

Safety and security are paramount

The prevention of ignition and development of thermal runaway is the main safety concern. As the battery is immersed directly in cooling liquid, the entire area must be sealed with specialist sealing elastomers that must be selected correctly in order to show a certain level of chemical and environmental resistance, ideally over the lifetime of the vehicle.

At Datwyler, we are conducting experiments and performing precise analyses on various types of cooling liquids in contact with different materials and from these tests it is possible to identify which types of polymers or elastomers are the most suitable for sealing these liquids.

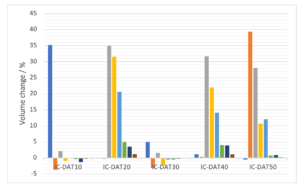

An important parameter to keep under control, even in the simulation phase, is thermal aging. The materials are tested at elevated temperatures (up to 100°C) for long periods of time (up to 1,000 hrs). From the first set of testing focusing on PFPEs, silicone and seed oil, it is demonstrated that Datwyler formulations based on IC-DAT10 and IC-DAT30 are performing very well in the majority of these cooling liquids and generally should be the sealing material of choice. Each IC-DAT code stands for a different elastomer family, thus the study compares performance of various polymer groups in selected fluids.

Following this rigorous testing process the physical properties of the materials are compared before and after immersion in these fluids. Change in volume presented here has been used as an indicator of the chemical stability in cooling fluids over time. Checks are also carried out to uncover thermal stability, any changes in tensile properties and setting under compression and leaks.

Figure 2. Results of chemical stability of standard rubber formulations in selected types of cooling liquids for immersion cooling – seed oil, silicone oil and various PFPEs.

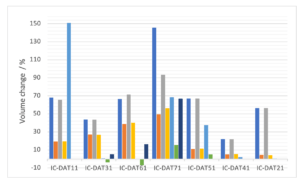

In the second set of tests shown in Figure 2, we have been focusing on bio-based and bio-degradable cooling liquids that are halogen free and non-toxic. All tested cooling liquids are classified with Global Warming Potential (GWP) 0 or 1. In addition, part of this study are also so-called hybrid liquids, that not only deliver the cooling effect but also lubrication of the propulsion system.

Volume change of standard rubber formulations after storage in these liquids show pronounced changes for the majority of the tested formulations. It can be seen that only the formulation with code IC-DAT41 would be a suitable candidate from all tested materials.

Figure 3. Results of chemical stability of standard rubber formulations in various types of bio-based cooling liquids for immersion cooling.

It is assumed that a change in polarity of the sealing material would provide improvements in the chemical stability of the sealing. Datwyler is working on other suitable material candidates to seal bio-based cooling liquids for immersion next to IC-DAT41. The test conducted at Datwyler with proprietary formulations highlights conclusively which materials are the best sealing for each particular cooling fluid on test.

Results of the next set of trials focusing on formulation optimization of selected materials will be presented in our next paper. Meanwhile, feel free to reach out for more details about our material development at materials@datwyler.com.

References

[1] Charlotte Roe, Xuning Feng, Gavin White, Ruihe Li, Huaibin Wang, Xinyu Rui, Cheng Li, Feng Zhang, Volker Null, Michael Parkes, Yatish Patel, Yan Wang, Hewu Wang, Minggao Ouyang, Gregory Offer, Billy Wu. Immersion cooling for lithium-ion batteries – A review, Journal of Power Sources, Volume 525, 2022, 231094, ISSN 0378-7753.

[2] W. Porter Harris, Fully-submerged battery cells for vehicle energy-storage systems, Patent No. US 9,692,095 B2, 2017.

[3] https://www.audi-mediacenter.com/en/press-releases/staying-cool-complex-cooling-systems-for-the-dakar-rally-in-the-audi-rs-q-e-tron-14439

[4] https://www.xingmobility.com/

[5] https://www.futurebridge.com/industry/perspectives-mobility/immersion-cooling-potential-alternative-to-traditional-battery-cooling/

Jakub Kadlcak is Head of Material Development Mobility and General Industry, Datwyler

https://datwyler.com/media/news/thermal-management-of-bevs-thermal-interface-materials

More Stories

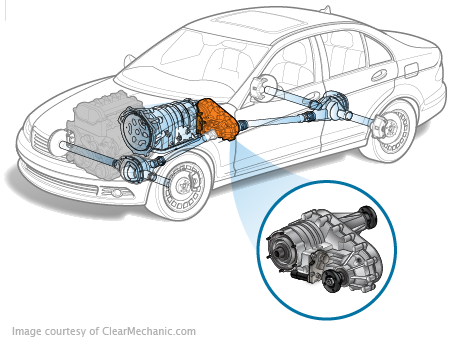

Automating ECU testing for automotive transfer cases using HIL

New LLC Switcher IC From Power Integrations Delivers 1650 W of Continuous Output Power

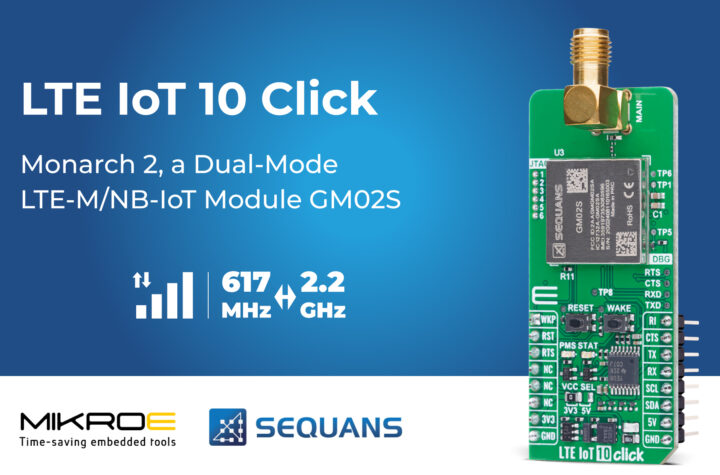

LTE IoT 10 Click Click board from MIKROE provides reliable IoT connectivity