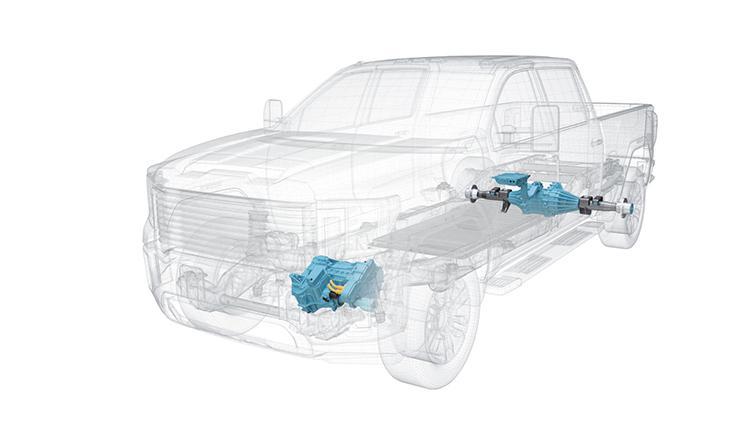

Cut-away of the Magna EtelligentForce is a battery-electric 4WD powertrain system

Faced with pressure to green their operations and reduce operating costs, distributors are moving away from internal combustion engine powertrains.

A study published by ResearchAndMarkets forecasts that the global electric commercial vehicle market size will grow from 353 thousand units in 2022 to 3,144 thousand units by 2030, at a CAGR of 31.4%. The increasing use of electric commercial vehicles for last-mile delivery of goods from warehouses to end-users is expected to boost the electric commercial vehicle market in the near future. Companies are considering the addition of electric vans and pickup trucks to their fleets to reduce fuel expenses and mitigate emissions, according to the study.

This is putting pressure on OEMs to provide electric vans and trucks as soon as possible. A “drop-in” solution for existing ladder framed vehicles is being offered by Canadian auto parts manufacturer Magna.

Automotive Industries (AI) asked Carsten Reisinger, Director, Global Product Management at Magna Powertrain, to tell us more about the company’s Magna EtelligentForce system.

Reisinger: The Magna EtelligentForce is a battery-electric 4WD powertrain system for pickup trucks and light commercial vehicles. It is designed to maintain these vehicles’ full capabilities and not compromise payload or towing capacities.

We call it a drop-in solution. You can fit it into an existing vehicle. Just replace the traditional axle with the electric equivalent. For sure, there are some other modifications needed, such as installing a battery pack instead of a fuel tank, but the conversion is relatively easy.

Based on customer surveys, Magna developed the new eBeam product family for class 1 to 5 vehicle applications for private and commercial use. There were several objectives: Firstly, an electric rear

axle must not have any disadvantages compared with ICE-based powertrains and drivetrains. Secondly, a cost-effective solution was crucial.

Thirdly, the new technology should enable full electrification within the typical ladder frame of existing pickup platforms.

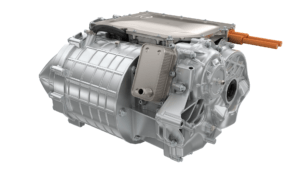

EtelligentForce features Magna’s eDrive technology at the front and its eBeam electrified beam axle at the rear. It is designed for high-payload vehicles, capable of towing up to 14,500 pounds – on par with its internal combustion counterparts in this truck segment. It can provide a total peak power of up to 430 kW – 250kW from the rear eBeam and 180kW from the front eDrive.

As a bonus, this solution omits the need for architectural changes to the vehicle and is totally customizable for automakers to prioritize key performance attributes. Magna’s eBeam replaces traditional beam axles, accommodating existing suspension and brake systems, and avoiding the need for expensive redesign of existing truck platforms. These benefits help automakers simplify the transition toward electrification of these vehicle segments.

AI: So, there is no need for expensive restructuring of existing truck platforms?

Reisinger: Correct. When we built our demonstrator, no structural changes were needed to fit the electric axle. We are using the same suspension components. We are using the same dampers the same m

ounting points, so no modification was needed. If you want to convert an ICE drive train into an electric truck, you need to do all the other modifications like removing the ICE powertrain and adding the battery. But with this exercise, it is really an exchange of components, with no need to do any further modifications.

AI: What about the battery?

Reisinger: The design provides space in front of the eBeam for battery packs

AI: And assembly?

Reisinger: Switching from the assembly of existing ICE vehicles to electric propulsion will not require any significant changes in assembly procedures of the OEM production line. Our colleagues in Graz are producing a traditional ICE model and an EV on the same production line. The eBeam is likely to be 50-60lbs heavier than an axle it is replacing, but there is no real difference for assembly staff so long as the hoist can cope with the extra weight. Then it is just a question of plugging in connections for the batteries, cooling system and general electrical interfaces.

AI: Will the e-version be cost-competitive?

Reisinger: For owners there will be definite savings in maintenance of the drive and powertrain. And there is it is difficult to answer that if you focus on the components specifically on the drive or the powertrain system, then I will say you would expect less maintenance of an electric powertrain system than one driven by an ICE motor.

AI: When will production start?

Reis

inger: Magna is currently building a new EV Center in Troy, Michigan, to support this development. Series applications are planned for 2025.

AI: What has been the response from the OEMs?

Reisinger: So, there is a lot of discussion with various OEMs in North America, Europe and Asia. I have to add the interest is coming from the fact that there is growing demand for electric vehicles in this segment. Magna EtelligentForce makes it possible to meet the demand without redesigning the chassis and building a new assembly line.

AI: What other electric vehicle components is Magna working on?

Reisinger: Magna is one of the preferred partners for all automotive electrified systems. Our products include inverter systems, ECUs and power closures. Our complete system expertise is based on a combi

nation of engineering and development know-how to drive as efficiently and economically as possible.

AI: What is next for Magna?

Reisinger: I can speak for our powertrain products, and we are looking forward to introduce our new eDrive technology in serial production in the near future. It will be one of the highlights for the company.

Looking further ahead, we are planning to introduce software as a product to our product portfolio.

More Stories

The Advantages of Cloud-Based Fax Software for Businesses

40 YEARS OF SILICONE GROWTH IN AMERICA

DuPont materials science advances next generation of EV batteries at The Battery Show