Evonik is continuing its material campaign in 3D printing. With INFINAM® RG 3101 L and INFINAM® FL 6300 L, the specialty chemicals company has developed two new photopolymers for industrial 3D printing. They expand the product line of synthetic resins launched just this year that are suitable for use in common photopolymer 3D printing processes such as SLA or DLP. Evonik will present the new products for the first time at the Formnext trade show from November 16 to 19 in Frankfurt am Main, Germany, in Hall 12.1 at Booth C69.

“We are relentlessly putting our global innovation strength into the development of new photopolymers that enable infinite applications. In this way, we are resolutely driving large-scale industrial 3D printing forward. The Formnext trade show is one of the most important international industry venues for 3D printing. We are therefore very pleased to present our latest ready-to-use high-performance materials here for the first time,” says Dr. Rainer Hahn, Head of the Market Segment Photopolymers in the Additive Manufacturing Innovation Growth Field at Evonik.

INFINAM® RG 3101 L is another specialty resin for use in SLA and DLP 3D printing technologies from Evonik’s innovation hub in Singapore. The ready-to-use material combines excellent impact resistance with high temperature resistance while exhibiting long-lasting thermomechanical performance. 3D components printed from INFINAM® RG 3101 L, such as drones, buckles, or automotive parts, can be processed by machine and remain fracture-resistant even when subjected to strong forces.

Elastomer photopolymer developed by Cubicure and Evonik With INFINAM® FL 6300 L, Evonik and the Viennese 3D printing company Cubicure are commercializing an innovation project jointly launched in 2019. The hot lithography printing process developed by Cubicure makes it possible for the first time to process highly viscous light-curing polyester-based resins. In contrast to conventional stereolithography, Hot Lithography creates objects at an elevated processing temperature using light-induced polymerization. The process allows a significantly wider range of processable components.

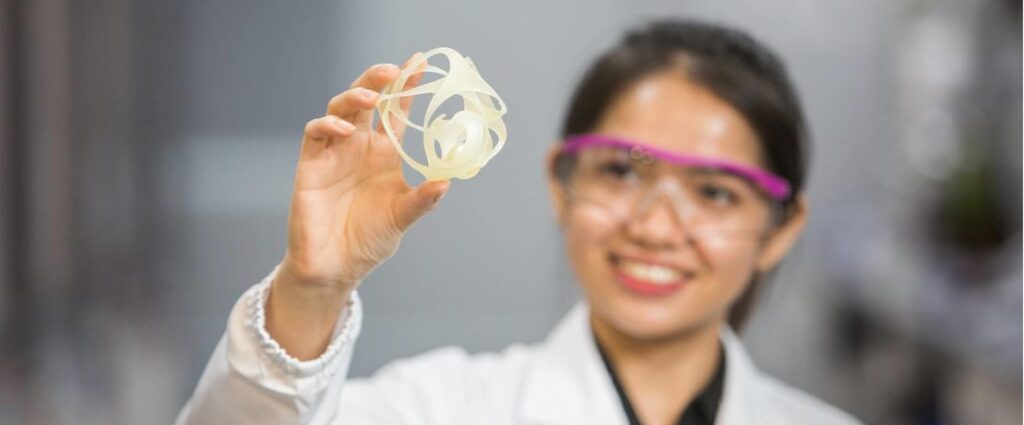

The result of this collaboration is the first industrially suitable elastomer from the photopolymer class. INFINAM® FL 6300 L enables the additive manufacturing of highly flexible 3D objects that excel in material properties essential for elastomers: in addition to outstanding low-temperature elasticity, its strengths include dynamic load cycles of up to one million load cycles.

“INFINAM® FL 6300 L enables completely new manufacturing possibilities in the field of elastic components. Thanks to the high precision with which the elastomer is processed in our hot lithography systems, it is possible for the first time to produce the most complex structures from a rubber-like material. The sports industry is showing great interest in using the material for cushioning elements in shoes, grips or backpacks,” says Dr. Robert Gmeiner, CEO of Cubicure.

INFINAM® materials for infinite 3D applications Evonik bundles its expertise in 3D printing in the Additive Manufacturing Innovation Growth Field. The strategic focus is on the development and production of new high-performance materials for all major polymer-based 3D printing technologies. Within this framework, Evonik has organized its product range of ready-to-use materials under the new INFINAM® brand.

Learn more about Evonik’s innovation topics at the Formnext 2021 trade show from November 16 to 19 in Frankfurt am Main, Germany, in Hall 12.1 at Booth C69 and on our website: \

Company information

Evonik is one of the world leaders in specialty chemicals. The company is active in more than 100 countries around the world and generated sales of €12.2 billion and an operating profit (adjusted EBITDA) of €1.91 billion in 2020. Evonik goes far beyond chemistry to create innovative, profitable and sustainable solutions for customers. About 33,000 employees work together for a common purpose: We want to improve life today and tomorrow.

About Smart Materials

The Smart Materials division includes businesses with innovative materials that enable resource-saving solutions and replace conventional materials. They are the smart answer to the major challenges of our time: environment, energy efficiency, urbanization, mobility and health. The Smart Materials division generated sales of €3.24 billion in 2020 with about 7,900 employees.

More Stories

Mosaic Click board from MIKROE delivers global coverage multi-band and multi-constellation tracking ability

Current transducer from Danisense selected for DC charging station testing device demonstrator at TU Graz

New Click board from MIKROE helps develop and train ML models for vibration analysis