Volkswagen is pressing ahead with the use of innovative 3D printers in car

production. For the first time, the newest process – known as binder jetting

– is being used to manufacture components at the company’s main plant in

Wolfsburg, Germany. Whereas conventional 3D printing uses a laser to build a

component layer by layer from metallic powder, the binder jetting process

uses an adhesive. The resulting metallic component is then heated and

shaped. Using the binder jetting component reduces costs and increases

productivity – for example, the components weigh only half as much as those

made from sheet steel. Volkswagen is currently the only car maker using this

3D printing technology in the production process. “Despite the ongoing

challenges of the coronavirus pandemic, we’re continuing to work on

innovation,” says Christian Vollmer, member of the Board of Management of

the Volkswagen Brand responsible for Production and Logistics. “Together

with our partners, we aim to make 3D printing even more efficient in the

years ahead and suitable for production-line use.”

Cedrik Neike, member of the Managing Board of Siemens AG and CEO Digital

Industries: “We are very proud to support Volkswagen with our innovative 3D

printing solutions. Our automation and software solutions are leading in

industrial production applications. Using this technology, Volkswagen will

be able to develop and produce components faster, more flexibly and using

fewer resources.”

To achieve this innovative advance, Volkswagen has invested an amount in the

mid-double-digit million euro range over the past five years. In addition,

the company has entered into a software partnership with Siemens and

expanded its existing collaboration with printer manufacturer HP Inc. With

the first full-scale use of binder jetting, they intend to acquire important

experience and learn, for example, which components can be produced

economically and quickly in the future or how additive manufacturing can

support the digital transformation of production at Volkswagen.

HP is providing the high-tech printers needed and Siemens the special

software for additive manufacturing. One key process step that has been

worked on jointly by Siemens and VW is optimizing the positioning of

components in the build chamber. Known as nesting, this technique makes it

possible to produce twice as many parts per print session.

From summer, the three companies intend to establish a joint expert team at

the high-tech 3D printing center which opened in Wolfsburg at the end of

2018 and enables the manufacture of complex automotive components using 3D

printing. The center also trains employees in the use of these technologies.

By 2025, the aim is to produce up to 100,000 components by 3D printing in

Wolfsburg each year. The first components made using the binder jetting

process have gone to Osnabrück for certification: components for the A

pillar of the T-Roc convertible. These weigh almost 50 percent less than

conventional components made from sheet steel. This reduction alone makes

the process especially interesting for automotive production applications.

Volkswagen has already successfully conducted crash tests on 3D-printed

metallic vehicle components. Until now, the production of larger volumes was

not cost-effective enough. However, the new technology and the collaboration

will now make production-line use economically viable.

More than one million components printed in 25 years

Volkswagen has been using 3D printing for 25 years, starting in Technical

Development with the goal of accelerating vehicle development and reducing

costs. Today, there are 13 units at the Wolfsburg plant using various

printing processes to manufacture both plastic and metal components. Typical

examples are plastic components for prototypes such as center consoles, door

cladding, instrument panels and bumpers. Printed metal components include

intake manifolds, radiators, brackets and support elements. Over the past 25

years, more than one million components have been produced.

Volkswagen’s collaboration with Siemens is part of a comprehensive strategic

partnership in the field of digital production platforms. Volkswagen Board

of Management member Vollmer: “I’m pleased that we have a strong and

innovative partner in Siemens so we can start working on the car production

processes of the future. The example of 3D printing shows that this

transformation harbors many diverse opportunities for innovation.”

More Stories

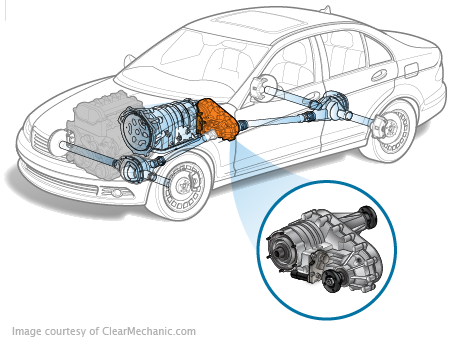

Automating ECU testing for automotive transfer cases using HIL

New LLC Switcher IC From Power Integrations Delivers 1650 W of Continuous Output Power

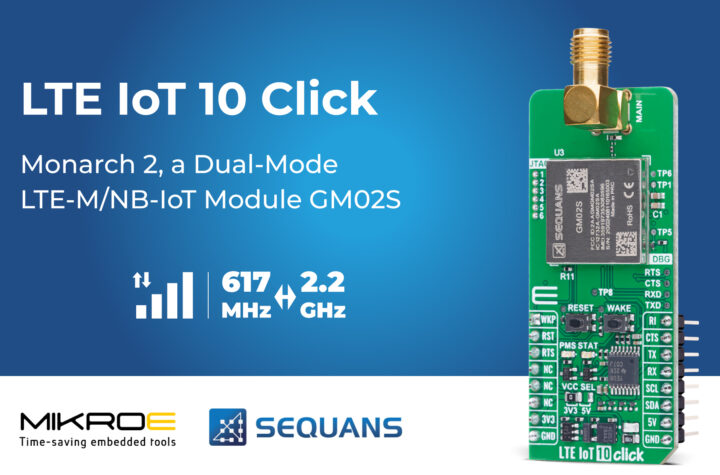

LTE IoT 10 Click Click board from MIKROE provides reliable IoT connectivity