Engineers around the world are able to continue developing new components and technology remotely from home thanks to the growing power of virtual manufacturing which simulates product design and engineering functions, as well as manufacturing processes.

Automotive Industries (AI) asked John Janevic, Chief Operating Officer of MSC Software (Hexagon), to tell us more about “virtual” manufacturing and design.

Janevic: This is a challenge that our customers are coming to grips with during lockdown. Typically, in an automotive design office the CAE engineer will be sitting with her colleagues and talking to them on a regular basis asking questions such as “is this the way you do this? Does that look right to you? Does it seem we are getting the right answers?” That feedback is critical.

It is fortunate that we at MSC have the same telecommuting infrastructure in place as most of our customers, and we have been able to replicate the virtual design office. From what we see customers have been quick to adapt. Our monitoring of the support questions we get tells us that most of our customers have figured out how to communicate remotely. They can also replicate a lot of their computer-aided engineering processes from home.

Another trend we monitor is the usage levels of our software. There are a lot of seats of MSC software deployed out there. At a company level we find that usage is solid and stable. The numbers are essentially the same today that they were one month ago or two months ago, which is encouraging to me because if our customers were struggling to work from home then we would see a decrease in license usage. To me it is encouraging that we’ve been successful in getting remote systems up and running, while customers have been able to continue to use our simulation software in much the same way as they have been before.

AI: Please tell us about your offer to provide free e-learning and “work-from-home licenses” for your computer-aided engineering software.

Janevic: As a company we were able to adapt pretty quickly. We have procedures in place for business continuity – and we develop software. We don’t build cars. Our ability to switch to a work from home situation was pretty straightforward. But, it became obvious pretty quickly that our customers were struggling to adapt to the new work-from-home environment as they could not access their CAE software.

By the middle of March, we were receiving feedback from customers in different locations around the world. We quickly recognized two challenges: One was that customers needed an urgent response. Last week they were working from the office, and this week from home. In order to cut through the licensing red tape, we set up a MSC One emergency license server to ensure that there is license continuity for our customers between the office and home.

*MSC One is a token-based licensing system used by companies to provide employees access to MSC Software’s portfolio of tools.

AI: How close to the real thing is virtual manufacturing?

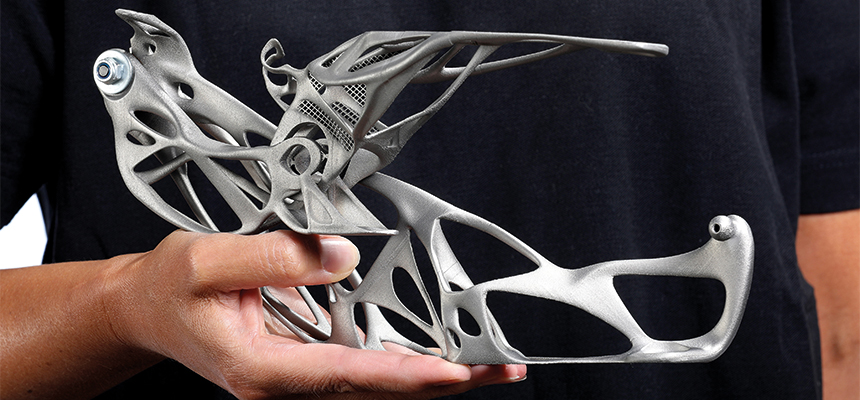

Janevic: It is quite close. The financial return on manufacturing simulation is pretty attractive. Our customers are using it because they get great results and they are able to make decisions and avoid massive expenditure by choosing the wrong tooling or through poor die design and excessive scrap. The alternatives of 3D printing or additive manufacturing can be expensive as well, so you want to make sure that you are right the first time.

AI: Does the industry have the necessary skills?

Janevic: It is a work in progress. In some ways, you can look at what we are doing with our e-Learning platform as an educational mission. Hundreds of customers have capitalized on the opportunity to learn new things. They are also learning to do things better with things like university courses in Germany and India which specialize in manufacturing process simulation. Customers are definitely investing time in learning. It is a rapidly growing segment of our business and it is in the area also where MSC really fits nicely within the Hexagon portfolio.

AI: Do you see the situation with the COVID crisis as an opportunity?

Janevic: There is the old saying “in crisis comes opportunity”. Certainly, from our standpoint we are trying to be very careful not to be very opportunistic taking advantage of the situation. But, for our customers, it is not easy to walk down the hallway to the prototype area, or the test lab and to be able to interact with the physical system in the same way that they have been able to do in the past. It has become more important for them to be able to do more simulation, to be able to simulate a wider range of scenarios and look and understand how the different load cases are affected by the inputs.

AI: Where do you see yourselves positioned in the near future?

Janevic: One of the things that is going to be changing as the result of this crisis is cloud high performance computing (HPC), which has been a buzzword for some time. Some of our more traditional customers, as well as conservative software companies, have been somewhat hesitant to fully embrace it due to concerns around data privacy and security.

One of the things that this Covid-19 crisis makes very clear is that we need to move faster. Not only in what we as a software company are doing, but also our customers. Working from home off a laptop or desktop machine our customers could turn to the cloud to access the high-performance computing power they need.

We have established ourselves as partners in cloud HPC, working closely with infrastructure providers. You will see the results in the not so distant future. Our having to work from home helped re-enforce the importance of cloud computing for both our customers and ourselves. With cloud computing power, our customers can be more than moderately functional. They will be able to enjoy the same type of highly detailed comprehensive simulation work that they have been doing in their office environment.

I think it will be a lasting trend beyond Covid-19 rather than a temporary need. We will be looking at both manufacturing simulation and a broader range of scenarios. Whereas in the past, the isolated simulation of a single part under specific conditions may have provided the results needed, we are now seeing customers wanting a more holistic approach. They want to be able to include more conditions, such as weather and the relationship between different components when the vehicle is in use.

This computing power becomes more important when we talk about autonomous and semi-autonomous vehicles. The trend towards conducting multiple tests under varying conditions will continue.

More Stories

Automotive Industries (AI) Newsletter April 2025

GlobalLogic Pioneering Software-Defined Vehicles, AI Innovation, and Sustainable Solutions for the Future of Automotive Mobility

Cybord TCI – The Future of Manufacturing Integrity