As a cost-efficient answer to continually increasing demands on the absence of burrs and particulate cleanliness, Ecoclean has developed the EcoCvelox system. Its modular design allows a custom configuration and subsequent expansion, at any time, of equipment from a single source to provide a combined high-pressure deburring, cleaning and drying capability. Cycle times of only 15 seconds per pallet can be achieved. Further standard-setting features of the EcoCvelox system include a CAD/CAM interface for rapid and easy offline programming of the high-pressure deburring function plus highly dynamic part handling technology.

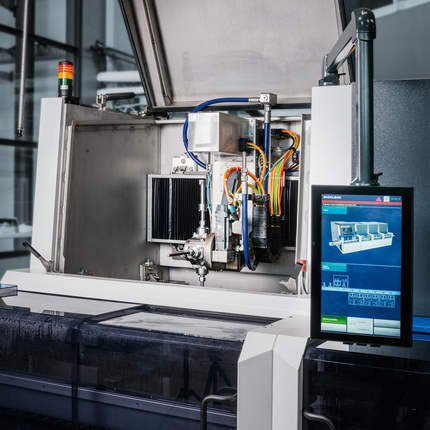

Hydraulic and pneumatic system components, small engine blocks, pump and valve housings, nozzles, transmission parts, steering and brake elements and other, mechatronic components – these are just some examples of parts subject to ever more stringent specifications regarding deburring and technical cleanliness. Formerly, meeting both requirements in an optimum manner called for the use of multiple equipment from different manufacturers. Now, with its innovative EcoCvelox concept, Ecoclean has developed a modular solution that combines 5-axis high-pressure deburring with various part cleaning and drying processes in an efficient and space-saving way. Moreover, in addition to flexibility, the new system sets standards in terms of the process-to-cycle time ratio, equipment level, operating convenience, ease of maintenance, and overall availability.

Maximum flexibility makes for optimum adaptability to user needs

The modular design allows users to configure individual systems that merge high-pressure deburring, part cleaning and drying from a single source, and to expand them as needs evolve. A combination with other products from this machine manufacturer, e.g., solvent cleaning prior to deburring in applications involving high oil input, is also possible. The diverse standard modules of the EcoCvelox are rated for parts measuring 200 x 200 x 200 mm which are supplied on pallets. This format covers most general industry applications.

Tooling configuration for the various processes is likewise adaptable to the specific parts. Thus, high-pressure deburring can be performed using the standard single spindle at up to 1000 bar pressure (or a maximum of 3000 bar should the need arise). An optional HP turret accommodating up to five different tools supports complex deburring operations. It provides a tool-to-tool changeover time of only 1.5 seconds. The tools for the spindle and the HP turret can be custom designed to match the given part and can be made by 3D printing. For part cleaning, the processes of injection flood washing, spray cleaning and selective rinsing are available and can be combined. Drying can be achieved by high-velocity air blow-off and/or vacuum, with the air blowing solution being integrated into a cleaning module as well.

CAD/CAM interface for easy programming of deburring operations

An absolute novelty in deburring systems, although a common feature on today’s machine tools, is the CAD/CAM interface that can be integrated into the equipment. It allows a transfer of part design data for purposes of programming the high-pressure deburring step. This can be done offline to load the data into the machine controller, which is easier and faster than any conventional teach-in method. In addition, this capability helps to set up deburring processes for new parts in minimum time and at low cost. For part identification, a camera system can be integrated. The result is an effective and cost-efficient deburring operation, even with ‘lot size one’ parts.

14.5 seconds process time in a 15-second cycle

Part handling for the deburring process takes place in one Y-axis in the basic version. However, for high throughputs and the associated cycle time requirements the module can be fitted with a second Y-axis. This allows loading and unloading to happen in parallel with deburring. The process time, at 14.5 seconds, thus becomes almost equivalent to the 15-second cycle duration. The same can be achieved for the cleaning and drying module by integrating a second, concurrently operating work chamber.

Pallets are moved between the individual processing stations by means of a linear drive system that is characterized by its highly dynamic performance and wear-free motor. It conveys the parts from one station to the next at a speed of 4 to 5 meters per second, thus contributing further to the system’s operating efficiency. The loading process can be manual or automated by means of a gantry system or robot.

At least 50 percent increase in tool life

Due to process-inherent reasons, all tools used for deburring are subject to wear, which in turn results in a pressure drop. This means that tools need to be replaced after a certain number of operating hours. On the new EcoCvelox, a patented software and a VFD-controlled high-pressure pump ensure that the process pressure is readjusted for this effect. This smart solution, providing a continual adaptation of the high-pressure level, extends tool life by at least 50 percent while boosting overall equipment availability.

For a fast and efficient tool change, the deburring module has a lateral maintenance door. This provides easy access to both the lance of the single spindle and to the turret-mounted high-pressure tools.

A smart solution for easy and effective operator control

Another feature contributing to the equipment’s high process reliability and availability rates is its new intuitive operator guidance system. On the 19″ flat screen monitor (HMI), all of the system’s modules are presented separately and clearly in a complete overview diagram, similar to a smartphone display. If a problem occurs, this is indicated by a color change of the affected module, e.g., to a shade of yellow or red. As the digital documentation is integrated into the HMI, it suffices to touch the image of the respective module briefly on the touch screen to view a process technology diagram, flow diagram or electrical circuit diagram in which all installed components are neatly shown, with the “malfunctioning” component (e.g., a pump) highlighted in a different color. A detailed view of this item can in turn be pulled up at the touch of a finger. Various functions such as activating or deactivating this component not only support fast intuitive troubleshooting but also supply clear problem-solving information. Moreover, the lists of wear parts and spare parts featured in the digital documentation will facilitate part ordering if necessary.

Due to its high flexibility in terms of both equipment configuration and process design, the EcoCvelox is an efficient, one-stop solution for all deburring, cleaning and drying needs. To avoid exhaust air, the system can optionally be equipped with an energy efficient air recirculation system.

The SBS Ecoclean Group develops, produces and markets forward-looking machinery, systems and services for industrial part cleaning and surface treatment applications. Its globally leading solutions help companies around the world in conducting efficient and sustainable manufacturing to high quality standards. The client base comes from the automotive industry and its suppliers in addition to a broad range of market sectors ranging from medical equipment, micro technology and precision devices through mechanical and optical engineering to power systems and aircraft industry. Ecoclean’s success is based on innovation, cutting-edge technology, sustainability, closeness to the customer, diversity and respect. The Group employs a workforce of about 900 people at its twelve sites in nine countries worldwide.

More Stories

AVL ThermalLab™ brings dynamic road VTMS conditions to the laboratory

Sika – where battery storage technology for EVs, wind and solar meet

Driving Change with Circular Aluminum: Hydro’s Role in the Automotive Future