The battery pack of a Rheinmetall Automotive test/demonstration emonstration vehicle built on a FIAT 500 platform has a storage capacity of 29 kW/h. Fitted with a new-generation electric motor the vehicle reaches a top speed of 135 km/h and achieves a range of up to 250 km. These parameters are achieved without encroaching on the luggage or the passenger compartment space normally available on the series version of this vehicle, according to the company.

Rheinmetall Automotive sees this configuration being rolled out into series-production project, with the flexibility for both the motor and housing to be adapted to meet customer needs. The Tier 1 autoindustry supplier and member of the Technology Group Rheinmetall, is responding to the increasing electrification of drivelines in its own product range. Among the new products developed by the company are a modular battery pack and a 90-kW electric drive unit. The new systems are currently installed in the Fiat 500 test/demonstration vehicle. The company has also developed a thermo module that significantly reduces energy consumption when heating or cooling electrically operated vehicles.

Rheinmetall Automotive draws on decades of engineering expertise in electric drive systems for auxiliary vehicle assemblies.

Back in 2004, through its Pierburg subsidiary, it developed the first all-electric coolant pump for the main cooling system, which was then successfully installed and launched in the six-cylinder BMW engines.

An electrically commutated water-recirculation pump developed by Pierburg at its location in Hartha, Saxony, has since its introduction in 2015 been installed in over 50 million vehicles and other pieces of equipment by the world’s foremost manufacturers and suppliers.

Other new additions to the lineup include electric motor housings and battery boxes, which will soon be series-manufactured in

aluminum by Rheinmetall Automotive for international OEMs. The company’s product range for electric mobility is supplemented by electric oil and vacuum pumps, electric coolant valves and actuators, an electric air-conditioning compressor along with heat pump module, as well as special lightweight components in aluminum.

Rheinmetall Automotive is focusing on and specializing in the areas of energy storage and electric drive systems and their peripherals.

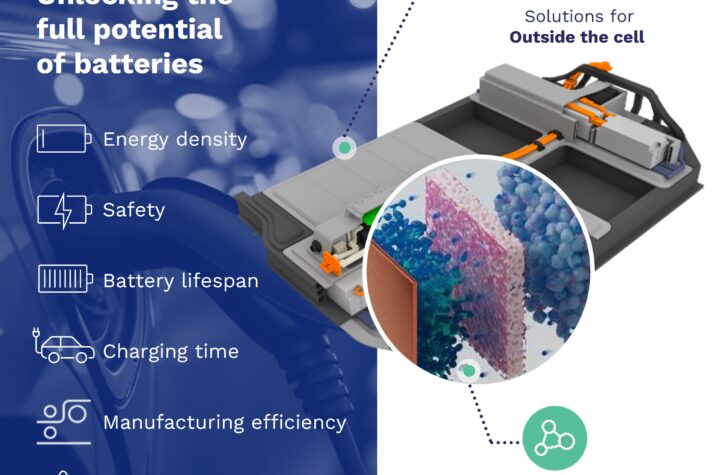

In the case of battery packs, it is pursuing a strategy that attracts OEMs because it allows the integration and thermal conditioning of a variety of battery cell types. Concurrently, it is introducing its own electric drive system with specific performance characteristics.

Underfloor battery packs safely protected

In the design of the new battery pack, Rheinmetall Automotive has worked from the premise that future electric vehicles and

hybrids will largely use underfloor batteries which do not reduced the vehicle’s loading capacity to any major degree while offering advantages in terms of weight distribution and possible integration with the vehicle’s structure.

The basic structure of the battery pack developed by Rheinmetall Automotive is made from aluminum into which customer-specific battery modules can be integrated. The packs have their own cooling system and are shielded from intrusion by a composite-fiber structure developed by an affiliate within the Rheinmetall Group specializing in protection systems. The arrangement allows for high energy density in relation to weight and, thanks to its compact footprint, permits very flexible and wide-ranging use in electric vehicles.

Electric motor with concentrated winding

The new drive unit is a synchronous permanent-magnet motor reflecting Rheinmetall Automotive’s many years of experience

and expertise in high-volume production technology.

The 90-kW high-voltage motor is of polyphase design and features a concentrated winding for optimum space utilization. On Rheinmetall’s test/demonstration vehicle the motor is coupled with a single-stage gear unit. The drive system to be manufactured by Rheinmetall has adaptable output and torque characteristics.The present design is tailored to smaller-sized vehicles, but it can be scaled to power larger vehicles as well.

Heater/cooler module extends range of electric vehicles

The company also offers a heater/cooler module that, by using a heat-pump function, significantly reduces energy consumption when heating/cooling electrically operated vehicles. Current road trials take into account all the heat generated during driving to enable the components to be set to the best-possible operating temperature.

The heater/cooler module is intended as a key component of the air-conditioning system. Existing assemblies such as the drive motor and generator are integrated as heat sources into the vehicle’s heat management system. The reproducible measurements obtained from the test series on an electrically powered small-car prototype under defined drive and ambient conditions complement previous test results.

Accompanying the tests as a recognised and independent party is TÜV Süd e.V., which also provides a wind tunnel for comparative measurements. The range-extending impact of the heater/cooler module has already been demonstrated in previous tests conducted by Fraunhofer Gesellschaft on other vehicles at normal temperature as well as test bench measurements on the module itself.

Proof of performance is documented by directly comparing the mileage range of the pre- and post-integration vehicles. The necessary measurements are carried out at a variety of ambient temperatures and according to the New European Driving Cycle (NEDC). When combined with smart controls for the heat management system, the heater/cooler module helps extend the vehicle’s mileage range without any compromise in driver or passenger comfort. Until now, the vehicles had used electric heaters which correspondingly shortened the mileage range and operating cycles.

Plug-and-play advantages

Apart from maximum energy efficiency, the heater/cooler module offers other advantages. The compact module is designed ready-to-operate and can be installed where most convenient in the vehicle. To integrate it with the vehicle’s HVAC (Heating, Ventilation, Air Conditioning), the customer simply connects the four supply lines of the secondary circuit and power supply. Installation times are accordingly shorter. With this plug-and-play heater/cooler module, it is also possible to carry out the necessary leakage tests on the refrigerant lines, add the refrigerant and start up the system outside of the vehicle.

Refrigerant losses and therefore greenhouse gas emissions are minimized through the combination of hermetic sealing of the refrigerant circuit and a minimum number of connecting elements. Its compact design also reduces the required refrigerant volume.

More Stories

Arkema: from cell phone to EV batteries in 40 years

BRANO and DOMO join forces to replace aluminum with TECHNYL® polyamide

trinamiX – will cars function like Smartwatches in the future?