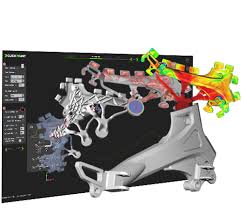

solidThinking announced the latest release of Click2Cast, a powerful casting simulation technology. Click2Cast is designed for beginners and experts alike to predict the manufacturing feasibility of a product’s early design process – minimizing downstream design change orders and retooling costs.

“The beauty of this release is that it includes the addition of advanced simulation capabilities without introducing complexity to the carefully designed user experience,” says Ravi Kunju, Vice President of Manufacturing Solutions for solidThinking. “As manufacturers strive for higher-performing, light-weight casted products, Click2Cast is an ideal solution to rapidly explore the manufacturability of these aggressive designs and make changes early in the design stage to mitigate production risks.”

Juan VILAR, Managing Director of Sandhar Technologies Barcelona states, “Quality of our castings is paramount at Sandhar, due to the nature of safety products we make for our customers. Click2Cast helps us during the entire process, from early quotation all the way to the virtual tryout of the product and tool development. Click2Cast is very easy to use and is the tool we need to support making our decisions quickly while keeping our operational cost in view.”

Key updates in the Click2Cast 4.0 release include:

* Simple process template for investment casting (also called lost-wax or precision casting)

* Easy modeling for inserts, chillers, sleeves and multiple-mold-materials

* Improved visualization of porosity including section cuts

* Newly integrated FEA meshing for improved geometry capture

“Click2Cast 4.0 has everything required to make high quality products, with just five steps,” says Martin Solina, Product Manager of Click2Cast. “Our focus is to delight the customers with fast, easy and accurate answers while keeping the solution affordable. We have been working very hard to give access to casting feasibility simulation to product designers, and manufacturing engineers, so they can have a common purpose and framework to produce great and defect-free products for their customers.”

Click2Cast is part of solidThinking’s manufacturing solutions suite that also includes Click2Extrude, for metal and polymer extrusion, and Click2Form for sheet metal forming. “We feel that having the right tools for concept and detailed process simulation is essential in a world wherein quality and profitability are as important as meeting the challenging demands of the customers,” says Kunju.

For more information about the Click2Cast 4.0 release and to sign up for the latest Click2Cast webinar scheduled for October 6, 2016, please visit: www.solidthinking.com/click2cast

About solidThinking

solidThinking creates, develops, and markets technology that helps organizations make informed decisions and bring the most desirable products to market faster. solidThinking software is sold and supported by a global network of distribution partners and is also available as part of the Altair HyperWorks® suite. solidThinking is a wholly owned subsidiary of Troy, Mich., (USA)-based Altair. To learn more, please visit solidThinking.com

About Altair

Founded in 1985, Altair is focused on the development and application of simulation technology to synthesize and optimize designs, processes and decisions for improved business performance. Privately held with more than 2,600 employees, Altair is headquartered in Troy, Michigan, USA with more than 45 offices throughout 20 countries, and serves more than 5,000 corporate clients across broad industry segments. To learn more, please visit www.altair.com

More Stories

Mosaic Click board from MIKROE delivers global coverage multi-band and multi-constellation tracking ability

Current transducer from Danisense selected for DC charging station testing device demonstrator at TU Graz

New Click board from MIKROE helps develop and train ML models for vibration analysis