Automakers are test-driving a new torque-vectoring electric drive system by GKN Automotive that will make hybrid vehicles more efficient and dynamic. The ‘eTwinster’ technology is part of a range of new hybrid electric technologies GKN is showcasing to customers at its Wintertest proving ground in Arjeplog, Northern Sweden.

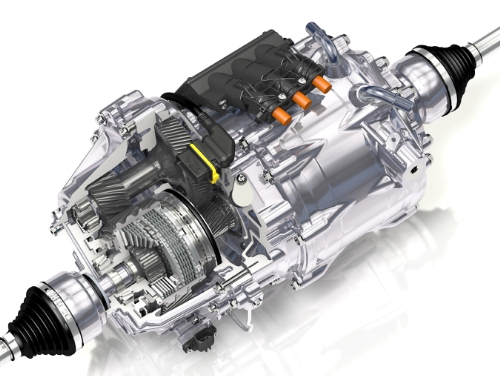

The eTwinster is a plug-in hybrid module that makes it simpler for vehicle platforms to offer electric all-wheel drive and torque vectoring. The driveline combines eAxle technologies proven in the Volvo XC90 T8 Twin Engine, Porsche 918 Spyder and BMW i8 plug-in hybrids and the twin-clutch torque vectoring technology that features in the Ford Focus RS and Range Rover Evoque.

Automakers’ vehicle dynamics experts are test-driving the technology in a premium SUV prototype. In the vehicle, a 60kW, 240Nm electric motor drives an electric axle with a transmission ratio of 1:10. A dual-clutch Twinster system then vectors the resulting 2,400Nm of torque between the rear wheels, significantly improving dynamic response and handling.

GKN Automotive President of Technology Peter Moelgg said: “GKN is the industry leader in eAxle technology with all our core eAxle and torque vectoring technologies now in production and proven expertise in integrating complete driveline systems. We have been building the momentum towards electric torque vectoring for some time. We believe our prototype torque-vectoring eAxle system represents the next step forward for the industry: a production-ready way to create higher performance hybrids that are more rewarding to drive.”

By 2025, GKN forecasts that 40-50% of vehicles will have some level of electrification, with a greater proportion hybrids’ power delivered from the electric motor. The eTwinster could be programmed and integrated into a vehicle platform for production within the next three years.

The eTwinster is part of a range of new eDrive technologies that GKN is developing to help shift the balance of power from engines to batteries in the next decade. Current mass-production vehicle platforms can only draw around 30% of their energy from a battery. GKN expects small, powerful, torque-vectoring electric axles could deliver 60-70% of the power in future vehicles.

Moelgg added: “GKN is focused on developing technologies that can achieve this crucial tipping point for electric drives in mass production. More powerful, dynamic electric drives from GKN will help put batteries in the driving seat and create new electric driving experiences for customers. The success of our eAxle systems in cars for Porsche, BMW and Volvo demonstrated how the right kind of hybridization creates new value propositions for the driver. Torque vectoring is the next step and we are excited to be demonstrating this technology during Wintertest.”

GKN has a history of developing innovations that make vehicles more responsive, controllable and efficient. The company has evolved in the last five years from being the world’s largest supplier of constant velocity joints and lightweight driveshafts into a leader in intelligent hybrid and all-wheel drive systems.

The eTwinster forms part of GKN’s family of Twinster technologies, designed to meet automakers specific vehicle needs.

ABOUT GKN

GKN plc is a global engineering group. It has four divisions; GKN Aerospace, GKN Driveline, GKN Powder Metallurgy and GKN Land Systems, which operate in the aerospace, automotive and land systems markets. Over 55,000 people work in GKN companies and joint ventures in more than 30 countries. GKN is listed on the London Stock Exchange (LSE: GKN) and recorded sales of GBP7.5 billion in the year to 31 December 2014.

ABOUT GKN AUTOMOTIVE

GKN Automotive is the world’s leading driveline technology engineer, an expert in conventional, hybrid and electrified power delivery. Encompassing GKN Driveline and GKN Powder Metallurgy divisions, GKN Automotive is a true integration partner to the world motor industry, delivering brand aligned driving experiences from city to sports cars and advanced all-wheel drive to intelligent hybrids. With 46 manufacturing sites across 22 countries, GKN Driveline employs over 26,500 people globally. GKN Powder Metallurgy, the world’s largest producer of precision powder metal components, boasts an experienced team of 6,500 people and supplies customers from over 30 locations across five continents.

More Stories

Some Ways How Motorists End Up in Collisions at U-Turns

Maximise Margins with Proven PPF Tactics

Finding the Car Boot Release Button – Tips and Tricks