Vertical machining offers a number of advantages compared to the more conventional horizontal configuration.

Automotive Industries (AI) asked Uli Kaiser, Business Development South East Asia for the EMAG Group, how the new generation of machines has helped the group to establish a strong hold in the market.

Kaiser: Automotive component manufacturers in Asia are experiencing severe labor shortages and many other problems resulting from manual work concept, such as inconsistent quality and productivity variations due to the “human factor”. The patented EMAG pick-up machines are the simplest and most effective way to reduce labor requirements and eliminate these problems without the complexity usually associated with fully automated lines.

AI: How do you interpret the trend of automation in South East Asian countries that before used manually loaded equipment?

Kaiser: It’s the single biggest threat to the industry and but at the same time a great opportunity to “step up” to world class manufacturing from the traditional Japanese Nagare (one piece flow) systems. In the past South East Asia has been a low cost manufacturing base for Japanese OEMs to serve domestic markets, with Thailand as a regional hub and controlling 90% of the market. In the future, we will see more European engagement, and with that also a transplant of European technology and manufacturing methods.

AI: How have your manufacturing solutions, benefitted automotive high volume manufacturers.

Kaiser: Due to their high productivity, EMAG solutions reduce the number of machines required by up to 50% and labor by up to 75% while achieving a capable manufacturing process. While the investment requirement is slightly higher than with “classic” machines, the cost per part machined is significantly lower.

AI: What factors led to the opening of a new production location in China?

Kaiser: We are living in the Asian Century, with much growth driven by China, India and South East Asia in the future. You can’t service this market from a location on the other side of the globe, so China is a logical choice for our second manufacturing location.

AI: How does energy efficiency and environment play a vital role for EMAG?

Kaiser: Germany has long been the country with some of the strictest rules to protect the environment – and the operators from hazards that are posed by operating machinery such as volatized coolant and oil and also noise. As Germany’s leading manufacturer of vertical, multifunctional equipment our focus has naturally also been safety and environmental protection. This is driven by the German law and our customers who demand nothing but the best solutions for their manufacturing environments.

AI: EMAG continues to contribute in the automotive industry. How has this Summit helped you?

Kaiser: Over the past two years, EMAG has been successful to develop the local market in Thailand, the natural gateway to the South East Asian machine tool market. Indonesia certainly is “the next big thing” and the summit was helpful to get orientation on the market and its future demand and allowed to reach out to potential clients and other players in the industry.

More Stories

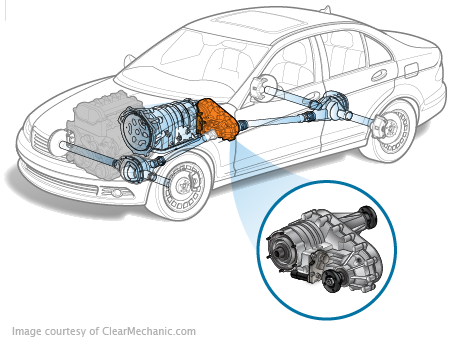

Automating ECU testing for automotive transfer cases using HIL

New LLC Switcher IC From Power Integrations Delivers 1650 W of Continuous Output Power

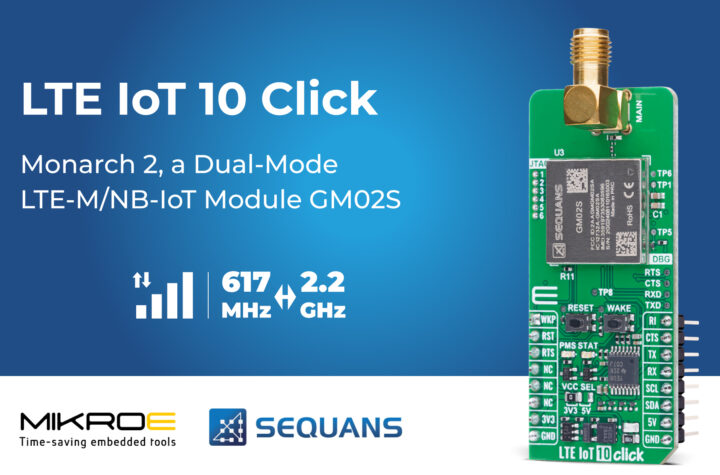

LTE IoT 10 Click Click board from MIKROE provides reliable IoT connectivity