The 27th NPE, the international plastics showcase held in April 2012 proved a resounding success in its new venue of Orlando, Florida.

The NPE exposition, which is held once every three years, was traditionally held in Chicago. It is organized by the SPI: the Plastics Industry Trade Association. NPE2012, which took place from April 1st to the 5th, attracted 1,933 exhibitors and 55,359 plastics professionals. The total exhibit space occupied at NPE2012 was 939,972 sq.ft, (87,326 sq.m), which was 23% more than in 2009.

Of the total attendance in 2012, 26% came from outside the United States- one-third from Latin America. Also setting a new record for international participation was the number of exhibiting companies from outside the United States—approximately 750, or 40% of the total. China sent the most international exhibitors — a little over 300, or 16% of all exhibitors. Another 8% came from the rest of Asia and the Mideast, and 10% from Europe. Canada sent 72 exhibitors—the second-largest country total after China. The 28 exhibitors from Mexico and South America represented the largest contingent ever from Latin America.

The automotive industry was, as usual, well represented at the NPE2012. Automotive components from fuel tanks, wire harnesses, instrument panels, and even new molded windshields were represented at the show. The improved economies and logistics of this new venue have encouraged many NPE2012 exhibitors to bring more machinery to the show, much of it to be operated on-site, according to John Effmann of ENTEK Manufacturing Inc, who is chairman of NPE2012.

Automotive Industries (AI) asked William R. (Bill) Carteaux, president and CEO of SPI to what factors he attributed the success of NPE2012.

Carteaux: Three initiatives by SPI played central roles in making NPE2012 a resounding success: our decision to move NPE to Orlando, our development of co-located events and special programs to provide attendees with a greater return on their trade show investment, and a worldwide program for marketing NPE2012. In addition, the steady recovery of manufacturing industries following the Great Recession helped to make NPE2012 bigger than our hard-hit show in 2009, but I would point out that in a number of key respects NPE2012 surpassed pre-2009 shows as well. For example, there were more exhibitors in 2012 than at each of the three previous NPEs. And the level of international participation—by both exhibitors and attendees—was greater than for any other NPE.

AI: How did the change in venue to Orlando help?

Carteaux: In comparison with our previous venue in Chicago, Orlando offered substantial cost savings for both exhibitors and attendees, dramatically streamlined the logistics of setting up and operating a booth, and was far more accessible to participants from the U.S. Southeast and Latin America. And then there was the hospitality factor: Over and over, NPE2012 participants remarked on how welcome they were made to feel and praised the responsiveness of the vendors they encountered. Clearly the people of Orlando were very happy to have us there.

AI: Were you surprised at the international response to NPE2012? Why is the exposition so important to the plastics industry?

Carteaux: SPI expected a stronger than usual international response, but what actually took place exceeded our expectations. NPE2012 set new records for the number of exhibitors coming from outside the United States, the share of registrations by international attendees, and participation by Latin Americans as both exhibitors and visitors. NPE is important to the plastics industry for a number of reasons, but I would say that its function as a showcase for new technology is its most critical role. Plastics professionals come to NPE with a compelling need to know about technological innovation. What they discover in the few days of show week strongly affects their decisions on capital equipment investment and raw material sourcing. Miss one NPE, and there is a gap of six years between opportunities to encounter the full range of new plastics technologies first-hand. To get an idea of how much influence NPE exerts on the course of the industry, consider that among the attendees at NPE2012 were representatives of more than 19,000 different companies, chiefly plastics processors, designers, and OEMs.

AI: What are some of the automotive technologies highlighted at NPE2012?

Carteaux: Complete automated manufacturing cells for producing automotive components were highlighted by a number of equipment companies. One of these incorporated a new technology for center consoles that replaced traditional buttons and switches with molded-in touch controls. Another fully integrated cell combined insert and over-molding to produce an intake manifold incorporating threaded bushings and three over-molded components, including a TPE gasket.

Weight reduction was, of course, a persistent theme and involved technologies ranging from parts consolidation through multi-material molding to use of glass bubble fillers. Saving weight was an important theme among exhibitors of polymer materials whose special properties—toughness, heat resistance, elasticity, or crystal clarity, for example—make possible the replacement of metals, glass, and rubber.

Renewably-sourced raw materials were widely exhibited at NPE2012, including grades developed especially for use in automotive components. Among the entries in the 2nd International Plastics Design Competition at NPE2012 were innovative automotive components providing substantial weight reduction as well as improved end use performance.

AI: What percentage of participants were involved with the automotive industry?

Carteaux: A large percentage at NPE2012 serve automotive manufacturers by supplying them with equipment systems, raw materials, or specialized services. While a final analysis of attendance at NPE2012 is not yet available, automotive industry involvement is again likely to be quite high. At NPE2009, for example, registrants were asked to list all of the end-use markets or industries that they served, and only packaging was listed more frequently than automotive.

AI: Tell us a little about some of the highlights of the conferences held as part of NPE2012.

Carteaux: SPE ANTEC® 2012, the world’s largest plastics technical conference, was co-located with NPE2012 and included an entire session on innovations in automotive plastics, along with other sessions dealing with process, materials, and engineering technologies of importance to automotive manufacturers.

AI: What do you have planned for NPE 2015? Will it be an even bigger/better show?

Carteaux: We certainly intend to make NPE2015 bigger and better. To start with, SPI, the NPE2012 Committee members, and the partner companies who worked with us on NPE2012 have begun a process of evaluation to determine what succeeded and what can be improved. We will be analyzing the wealth of information that has accumulated about the show and its participants, and we will be carrying out post-show surveys of exhibitors and attendees.

More Stories

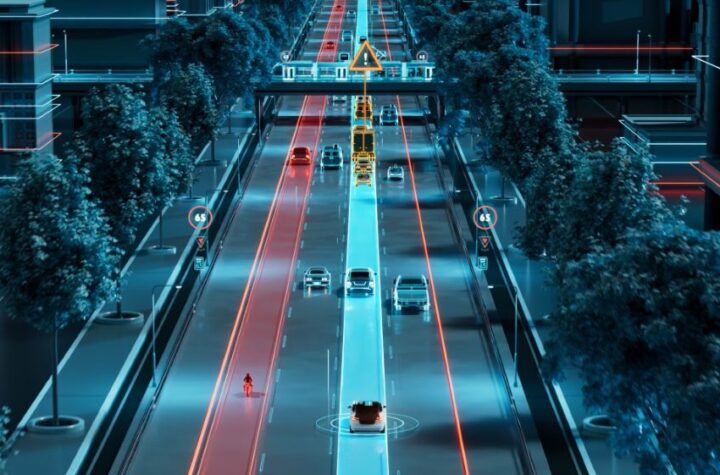

TomTom’s Orbis Maps with 3D Lane geometry set new standards for mapping precision

Accelerating The Development of Hydrogen Vehicles & Infrastructure – Europe’s Biggest Players Meeting at Premier Event

Automotive IQ Announces the 15th Annual Automotive Functional Safety Week 2025