Bekaert Diamond-Like Coatings, worldwide leader in performance engine coatings, recently installed a high energy centrifugal barrel micro-polishing machine for camshaft polishing. The machine will enable Bekaert to give camshafts the ideal pre-coating treatment, to ensure optimal smoothness of the surface before applying the black DLC coatings. Additionally, Bekaert will also service customers who are not looking to apply DLC coatings, but would prefer to have smooth camshafts for optimal engine performance.

Surface finishing – a perfect preparation makes half the success

The deposition of black DLC coatings is a precarious process that can only be executed by a DLC coatings expert, such as Bekaert. DLC (short for Diamond-Like Carbon) coatings are the protective layer one can find on coated engine components. These have a typically black color, which makes the coated components easily recognizable. In order to apply such coatings the polished components are put in a vacuum vessel and heated to temperatures between 200°C and 350°C (depending on the application). Using evaporated metals like Titanium and injected carbon gases a stack of layers is formed on the surface of the component. A typical stack will consist of an adhesion layer which bonds very well to the substrate material, a second layer to make the transition to the final functional carbon layer. Needless to say it is imperative the adhesion layers should stick extremely well to the surface of the component, which is why this needs to be treated beforehand.

“Our customers depend on strict and tight deadlines in terms of delivery. By taking care of both the surface finishing preparation and the coating of the components within the same facilities, they no longer have to worry about complicated logistics, extended lead-times and multiple suppliers. Bekaert can function as a one-stop supplier. We will smoothen the surface of the camshafts and apply the DLC coatings. They just need to drop them off.”, Tom Jenkins, Market Manager US at Bekaert, explains this new investment choice.

Niche market of camshaft polishing

In order to comply with the industry’s need for better performance, reduced friction and fuel consumption, engine manufacturers are looking to smoothen up the surface of the camshaft as much as possible. The oil lubrication within the engine has been thus optimized throughout the years that the components now rotate on a small layer of oil, making a smooth surface finish primordial for the engine’s functionality. Unfortunately, the investment in a microfinishing machine is a cost that cannot be made by many a small engine manufacturer. Since Bekaert has the logistics and equipment in place, they will therefore also service smaller customers looking for surface optimization of their camshafts.

“We understand the race industry need for a finetuned camshaft even without DLC coating application. A lot of engine builders have difficulty finding a specialized supplier who can handle just the polishing – we feel this is a missed opportunity. We don’t want to ignore this industry need and hope we help out many engine builders this way.”, adds Mark Boghe, Product Market Manager at Bekaert.

The microfinishing machine will be operating effectively as of June 2010 for existing and new Bekaert customers, as well as companies who do not want to invest in DLC coatings, but would like to have the camshaft polished. For the time being, Bekaert will only apply surface treatment to camshafts for the racing market. Bekaert plans to extend the product offering to other components in the latter half of 2010.

More Stories

AUO Returning to CES Showcase Next Generation Smart Cockpit 2025

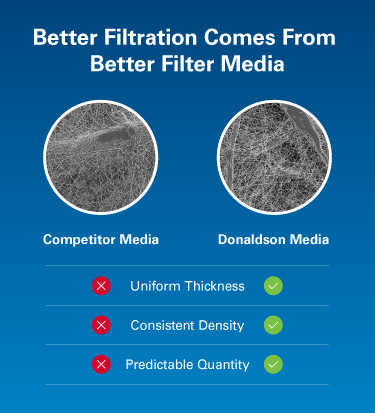

Donaldson Ultra-Web technology aims to set the standard in industrial filtration for cleaner air and cost-savings

Hydrogen’s Role in Decarbonising Sports and Entertainment Events