Driven by stiff competition, increasing pressure to reduce costs, and environmental regulations, automotive manufacturers are seeking new design concepts and manufacturing methods. Israeli company, Pulsar Ltd helps manufacturers address these challenges particularly in the automotive sector which provides up to 80% of its revenues.

Pulsar offers manufacturing solutions based on magnetic pulse technology which harnesses a high energy current that is discharged through a coil surrounding the work piece, and creates a fierce magnetic filed used to manipulate the metal. The technology enables dissimilar material combinations to be welded together to produce tougher and better quality materials than conventional welding.

Pulsar says that companies using this technology can cut the manufacturing process by as much as fifty per cent on top of benefiting from a completely “Green” process.

Rani Plaut, CEO of Pulsar, stated that although the well known and established technology was not invented by Pulsar, the company had perfected the process of solid state cold welding, otherwise known as magnetic pulse welding (MPW). “The company has refined the process to a level where it can be done with an affordable, small footprint machine, operated by any floor shop worker and serviced by the plant’s maintenance guy,†says Plaut.

According to him, most traditional welding techniques simply apply a lot of energy to two pieces of metal placed side by side, causing them to melt. The melted portions of the two pieces get mixed and cooled together and thereby create one piece. “There is only one small problem,†says Plaut, “heat distorts metal, so the welded area is dramatically weaker, corrosion sensitive and deformed. You also end up releasing a lot of the energy and products of the process into the environment including heat, radiation, smoke, gas and sparks. Many of the more advanced techniques such as laser, are trying to minimize these effects by making the heat source more focused, but this just leaves you with a lesser effect and does not eliminate the problem,†says Plaut.

Pulsar’s solid state cold welding can weld dissimilar metals using a cold process so a metal like aluminum can be welded to stainless steel, copper and many other combinations. Solid state cold welding has successfully replaced traditional welding in many products worldwide and serves as a technological enabler for products such as the new generation of air conditioning systems in automotive manufacturing.

Automotive Industries (AI) spoke to Rani Plaut, CEO of Pulsar.

AI: Please give us some examples of how your magnetic pulse solutions have helped automotive manufacturers.

Plaut: Magnetic Pulse Welding (MPW) technology adds value in three areas including improved quality, reduced costs and enabling mechanical designs and material combinations that are not possible with conventional welding methods.

We have seen various examples where implementing magnetic pulse welding has helped to reduce scrap and rework rates dramatically.

We have also seen examples where customers were able to reduce massive quantities of raw material by altering parts of their design. The modifications were made possible by MPW which reduced some of the constraints imposed by traditional welding methods. By using MPW, parts can be thinner and have the same mechanical strength as thicker parts that have been welded with traditional methods.

AI: You said earlier that a mid sized car costs about $3,000 to produce with a total production time of 24 hours in Asia – by how much can your technology cut this cost and time?

Plaut: There are certain inherent properties of magnetic pulse welding that enable cycle time reduction and cost savings. Traditional welding processes are measured by weld length per minute while MPW is under 0.1 seconds regardless of size. A 15 second welding process is therefore shortened to almost nothing. MPW is also a cold weld process, so cooling times are eliminated. Certain upstream and downstream processes including degreasing are also not necessary, and MPW significantly reduces costs by eliminating the need for consumables such as shielding gases and electrodes.

MPW is also a very clean and environmentally friendly process and since gases are not used, there is no need for costly ventilation systems which reduce costs significantly.

AI: How popular is solid state cold welding or MPW in the automotive industry? Have most companies opted for this method or is it still in a nascent stage?

Plaut: MPW is currently making inroads into the automotive manufacturing industry. Market trends such as light weighting have helped to promote this process as an alternative to other welding methods. Steel is being replaced by light weight aluminium, which creates a need for new joining methods such as MPW.

AI: What are the kind of automotive products that benefit from cold welding and why?

Plaut: One of the driving forces behind the move to adopt MPW is the implementation of R744 coolant in mobile air conditioning systems. This adds new requirements for the air conditioning system parts such as the ability to work in increased working pressures, as well reduce weight and lower costs. Certain parts in the air conditioning system, including accumulators and receiver dryers, are very suitable to magnetic pulse welding. We have seen a lot of interest from various manufacturers wishing to implement MPW for the production of these parts.

Another example is the new regulatory requirements for airbag canisters which have to withstand fire. New joining methods are needed, and MPW is uniquely positioned to answer these needs. There is also a trend to reduce electrical cable weight in cars by replacing copper cables with aluminum. The cable lug used to connect the cables will still be made from copper, and so connecting the lug to the aluminium cable is a big challenge which MPW can effectively meet.

AI: What are Pulsar’s future plans? What kind of new manufacturing technologies is the company developing?

Plaut: We are constantly working on expanding the applications of magnetic pulse welding. We focus on three dimensions including geometry, size and materials. Geometrically, we are focusing on tubes. In terms of size, we are constantly expanding the use of MPW on larger parts to meet customers’ needs. Another exciting application is the use of magnetic pulse crimping which replaces joining methods such as riveting and stud welding. Our crimping method is unique and advantageous since it offers an innovative method of joining metal to practically any other material.

Pulsar runs a programme called PREP (Pulsar Research & Educational Program) which brings together a community of opinion leaders and academic institutes. It offers specially priced systems, training and technical support to promote the use and understanding of magnetic pulse welding. PREP has over 50 active members who have helped to implement the technology in other area including the pharmaceutical, construction and white goods industries.

More Stories

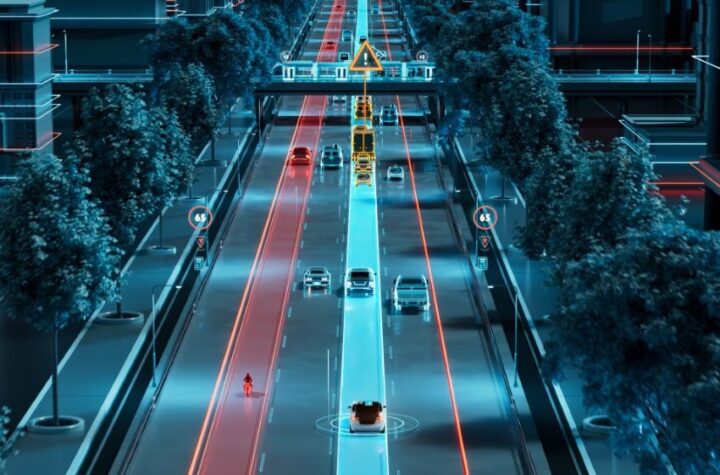

TomTom’s Orbis Maps with 3D Lane geometry set new standards for mapping precision

Accelerating The Development of Hydrogen Vehicles & Infrastructure – Europe’s Biggest Players Meeting at Premier Event

Automotive IQ Announces the 15th Annual Automotive Functional Safety Week 2025