Automotive Industries speaks with a cross-section of Israeli companies to understand better what innovation and creativity the country has to offer automotive companies

This March, the Israeli government gave the joint Israeli-Jordanian-Palestinian Peace Valley project a boost by labeling it a national project which means it will get preferential treatment and a clear passage through bureaucracy.

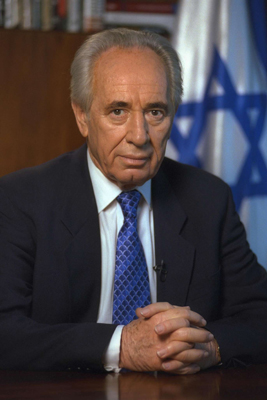

A brain-child of Israeli Vice Premier Shimon Peres, the project includes an industrial and agricultural park, an airport and railway links between the three partners. Peres’ idea being that the 500 kilometer project that will stretch from the Red Sea to the Yarmuk River, will provide stability in the region. The bulk of the funding for the project is expected to come from the World Bank, foreign governments and private investors.

Peres is also pushing to place Israel firmly on the automotive map by making it a regional hub to test the efficacy of electricity-powered cars as well as other novel cars. The pilot program is an initiative with Israeli technology guru Shai Agassi of SAP and the government.

New vehicle testing ground

Peres is reportedly in talks with European and Asian car manufacturers to promote the idea of using Israel as testing ground for new cars. The two projects will help Israel emerge as a hub for automotive companies.

The country’s automotive exports are reportedly US$500-million currently. A major source of interest in Israel for auto companies is die-cast magnesium. The country has large stores of the alloy. Volkswagen AG and the Israeli company Dead Sea Works produce and market magnesium across the globe. Magnesium is the lightest of all commercially available alloys. Israel is also known for its plastic, metals, rubber auto components, parts and sub-assemblies.

The electronics sector is experiencing impressive expansion. This is an area where Israel’s experience in developing electronic systems in the defense sector gives the country a competitive edge. A growing number of high-tech companies is involved in the automotive industry, designing and supplying manufacturing control software, navigation and control systems, diagnostics, testing, measurement, and on-board driver assistance systems.

Supported by over 3,000 members, The Israel Export & International Cooperation Institute or IEICI is the primary organization that facilitates trade opportunities, joint ventures and strategic alliances between international businesses and Israeli companies. “Israel’s unmatched pool of highly skilled workers, world-renowned research capabilities, and free trade agreements with all major economic powers make it the ideal place to do business. Whether you’re in the market for high-tech systems or consumer goods, Israeli market is a reservoir of technological capabilities, innovative solutions, quality manufacturing, trade cooperation opportunities and experienced, talented professionals,” says a blurb on the IEICI website.

The IEICI, set up in 1958 as a non-profit organization, is a joint venture between the Israeli government and the private sector. The IEICI operates in most countries through official Israeli official representatives like embassies, commercial and economic attaches and maintains strong business cooperation with diplomatic and commercial representatives in Israel, as well as with international trade promotion organizations around the world. The organization helps promote 27 industry or technology sectors including automotive through business cooperation on all levels: technological, industrial and commercial.

Middle East Silicon Valley

Israel has a pool of highly skilled workers, winning it the sobriquet of ‘Silicon Valley of the Middle East’.

Israel’s list of automotive companies that offer a range of products to the world is impressive. One such is Recognix Technologies Ltd, a leading software and solutions provider of image processing applications. The company specializes in image processing technologies, image and video analysis, signal enhancement based on an innovative approach to pattern recognition, and system analysis awareness with extensive hands on experience.

Recognix core technology focuses on image processing through innovative approach and algorithms enabling a wide spectrum of business activities both in the security and military fields, as well as the automotive industry. The company has a joint venture with Magal Engineering Ltd to develop and supply the vehicle industry with vision based situation awareness and safety embedded systems. Its advanced drivers assistance system or ADAS, provides advanced information to drivers from areas that drivers cannot maintain constant sight of or dead area. Recognix plans to develop innovative systems that will be based on a small size processing unit, LCD screen and several cameras built into the car body.

Also helping Israel get its Silicon Valley tag, is Nextec Technologies. It specializes in high precision, non contact 3D scanning for geometry inspection, quality control and reverse engineering applications. Nextec says its goal is to help its customers achieve improved, high precision and fast geometry inspection methods for more economical manufacturing and improved quality control process.

Nextec scientists have developed proprietary optical metrology – laser scanning technology that provides solutions for quality inspection, digitizing and real-time process control. These special products – the WIZprobe scanning sensor, The WIZinspect and WIZblade systems and the Hawk digitizer are providing edge of technology solutions to measurement challenges. The technology was installed in Rolls Royce China’s production floor in 2005. Similarly, it was installed in Volkswagen’s Mexican facility. Nextec implemented its first project at Rautenbach-Guss, a German engine head manufacturer for Volkswagen, Audi and Mitsubishi during 2003.

Magnetic Pulse technology

Another company, Pulsar Ltd. offers innovative manufacturing solutions that enable a new level of product design and production possibilities.

Based on its proprietary magnetic pulse technology, Pulsar solutions enable companies to achieve higher quality processes, using a wider range of materials with fewer tools and processing steps, at significantly less cost than ever before. Pulsar says it has invested over 100 man years in bringing its products to maturity and today many leading manufacturers worldwide are producing parts using the Pulsar systems.

For the automotive sector, Pulsar offers a range of products that helps automotive manufacturers who are seeking new design concepts and manufacturing methods. “Weight reduction, quality improvements to avoid rework and warranty costs, and design simplification to reduce manufacturing costs, are becoming major challenges to car makers and their suppliers. Pulsar helps manufacturers address these challenges.

Pulsar solutions, based on magnetic pulse technology, reduce the complexity and cost of manufacturing auto components while increasing their reliability,” says a statement on the company website.

The products include automotive climate control elements such as accumulators and receiver dryers for automotive climate control systems which do not use the typical aluminum parts with thin walls which are assembled by MIG or TIG welding methods. Instead, its Pulsar MP-Weld T, which is a cold weld, eliminates problems like leaking completely. The company says MP-Weld delivers a very high quality, stable and strong weld within an extremely short cycle time. The company also manufactures leak-free fuel filters, exhaust parts, drive shafts, power cables and fuel pipes using its MP-Weld process.

Vision Systems

Another Israeli firm that has been a pioneer in its area of expertise is Mobileye Vision Technologies. The company is a pioneer in the development of vision systems for intelligent transportation systems or ITS. Founded in 1999, the company is recognized as the leading provider of vision-based driver assistance technologies and has been selected by BMW and other major automotive companies worldwide for their production vehicles starting from 2007.

Mobileye says its mission is to develop vision systems for accident reduction and driver assistance. These systems work as a sort of third eye for the driver. Applications such as distance keeping, adaptive cruise control, lane departure warning, forward collision warnings, are tackled with Mobileye’s systems.

“Studies in the U.S. and Europe have shown that providing an early warning in case of an imminent crash can dramatically reduce accidents and casualties. However, the limited application of standard systems available today (based on Radar and LIDAR sensors) and high price have hindered their widespread adoption in the market. Mobileye’s EyeQ vision system-on-a-chip or SOC, represents technological breakthrough that combines high performance, low cost and allows consolidation of multiple applications on a single platform is positioned to revolutionize the implementation of driver assistance systems on a mass scale,” says the company.

Mobileye says it will start delivering its technology in six production platforms starting this year with BMW and two other leading car manufacturers in the US and Europe. Additional OEMs and Tier 1 suppliers have Mobileye evaluation systems installed in vehicles for advanced development and research programs with an additional number of production intent agreements already in place. Mobileye’s R&D center is located in Jerusalem, Israel, with sales and marketing offices in Cyprus, Detroit MI, USA, and Tokyo, Japan. The company has over 160 employees worldwide.

Zinc and Magnesium

Apart from electronics, Israeli firms are known for their zinc and magnesium parts for the automotive industry. Ortal Diecasting specializes in the manufacture of zinc and magnesium die-casting parts, utilizing its knowledge to provide exceptional development, prototypes, tools, mould design, manufacturing and J.I.T supply to companies like Autoliv, General Motors and other automotive companies.

Similarly, Foamotive, specializes in foam-based products for the automotive industry. Set up in 1999, the company specializes in tailor-made foam parts for automotive seating, under-the-hood and outer shell applications. It says it is sole supplier of 30 out of the 32 parts it manufactures.

Israel’s Omen High Pressure Die Casting, is a specialist in high-pressure die-casting using non-ferrous metals like aluminum and brass. It manufactures auto parts like fuel pump covers and clutch pedal assemblies.

Mivrag Cold Forming Technology, is a global supplier of automotive parts that are made by cold forming. Cold forming is a forging process in which metal wire is cut, extruded and shaped on high force multiple-die machines. The company was established in 1952 at the Kibbutz-Ein Hashofet which was settled in 1937 and like other kibbutzim played an important role in the establishment of the State of Israel. Initially, the small communal society relied on agriculture for its livelihood. Today, the kibbutz is a strong and successful group that owns, manages and operates three profitable industrial companies.

European customers

In 1990, began exports to European automotive customers like the PSA Group, Volkswagen, Ford and Delphi Automotive Systems. Mivrag has a state of the art fully automated cataphoretic plating line (E-Coat). The line is the second of its kind to have been installed in the world. The tray-based system replaces the traditional labor-intensive hanging systems, ensuring consistent quality and competitive pricing and allows the plating of parts of a large variety of shapes and sizes.

Another member of the Kibbutz Ein Hashofet is Eltam and MAG. MAG supplies integrative mechanical and electro-mechanical assemblies for the automotive industry. “MAG benefits from in-house competencies including stamping, cold forming, electronics and finishing. When combining these competencies with an extensive network of global suppliers MAG ensures product superiority complemented by competitive pricing. Opel. GM, Audi and VW are customers,” says the company.

The third automotive firm in the Kibbutz Ein Hashofet is Eltam. The company is the largest manufacturer of ballasts in Israel and the Middle East. The company designs and manufactures ballasts and other magnetic and electronic accessories for the lighting industry. In addition to the above, the company has established itself as an approved supplier of cold forming parts and subassemblies to the automotive industries. The company exports to Western and Eastern Europe, the US, south-east Asia, Australia and Africa. It has a tie up with German lighting company Vossloh-Schwabe.

Instrumentation

ScanMaster Systems manufactures quality instrumentation, automated ultrasonic inspection and imaging systems and transducers which are used in various applications including automotive. Each ScanMaster UT system is integrated and has a number of core modules, including industrial PC-based digital ultrasonic instrumentation, production-oriented software packages and servo motion control hardware (for those applications requiring robotic manipulation). These modules are integrated in application-specific configurations, which depend on the inspection requirements for speed, number of channels, on-line display and report documentation.

Research & Development

Many Israeli firms have R&D facilities in Israel and manufacturing locations in countries like the US. Such as Friction Control Solutions or FriCSo, which was founded in 2003 by Dr. Boris Shamshidov and Dr. Alexander Ignatovsky, two scientists specializing in tribology, the science of friction, lubrication and wear. The company’s headquarters are located in Farmington Hills, MI, near Detroit – the heart of the US automotive industry. The R&D center is located in the Tirat Hacarmel Industrial Zone, Israel. The company provides patented, environmentally friendly nanolayer-based technology that significantly reduces friction between moving parts. The technology won the 2006 Frost & Sullivan Technology Innovation Award in the field of automotive coatings. The award recognizes FriCSo’s breakthrough Surface Engineering Treatment (SET) technology, which reduces the friction between moving parts using an innovative mechanical process.

“FriCSo’s solution is not a coating but delivers coating-like performance at a fraction of the time, cost and maintenance required by traditional solutions. Metal parts treated with SET enjoy high wear resistance and improved energy efficiency in the engines. SET is cost effective compared to using exotic metals (such as bronze) for metal-pairs design, DLC and other coatings and bushings, and even offers superior performance in certain applications. Being environment friendly, this technology does not produce any toxic waste and complies with the Environmental Protection Agency (EPA) restrictions,” said Amir Weisberg, CEO of FriCSo, Inc.

Electronic Encoders

Netzer Precision Motor Sensors, manufactures high quality position encoders that are based on a proprietary technology invented by Yishay Netzer. The company continuously develops its electric encoder technology to suit more and more applications. Netzer, has been responsible for innovative, multidisciplinary systems that involve electronic design, optics and mechanical design.

Then, of course, Israel has ISCAR run by Eitan Wertheimer, who is a key player in Peres’ plans to develop cars that run on electricity. ISCAR is a dynamic full line supplier of precision carbide metal working tools, producing a wide range of carbide inserts, carbide end mills and cutting tools covering most metal cutting applications.

ISCAR also provides metal working solutions in both engineering and manufacturing to major industries throughout the world. Many innovative products, designed specially according to customer requirements, have made ISCAR a world leader in manufacturing industries such as automotive, aerospace and die & mold production. Over half of the company’s sales are from products developed within the last five years.

More Stories

Mosaic Click board from MIKROE delivers global coverage multi-band and multi-constellation tracking ability

Current transducer from Danisense selected for DC charging station testing device demonstrator at TU Graz

New Click board from MIKROE helps develop and train ML models for vibration analysis